Data logging is the process of collecting and storing data from various sources for analysis and reporting. For the purpose of monitoring and optimising the performance of equipment and procedures in industrial automation systems, data logging is essential. The MicroLogix 1400 PLC provides data logging capabilities with its integrated data recording capability.

The MicroLogix 1400 PLCs data recording feature allows engineers and technicians to collect and store data from various sensors and other devices connected to the PLC. The data can be kept in local memory or on a removable SD card. The data logging function supports a wide range of data logging types, including cyclic logging, event logging, and change of state logging.

Cyclic logging is used to log data at predefined intervals, whereas event logging is used to capture data when a specific event occurs. Change of state logging is used to capture new data whenever the status of a certain input or output signal changes. Data that can be inspected and used for reporting, optimisation, and troubleshooting are logged by the MicroLogix 1400 PLC.

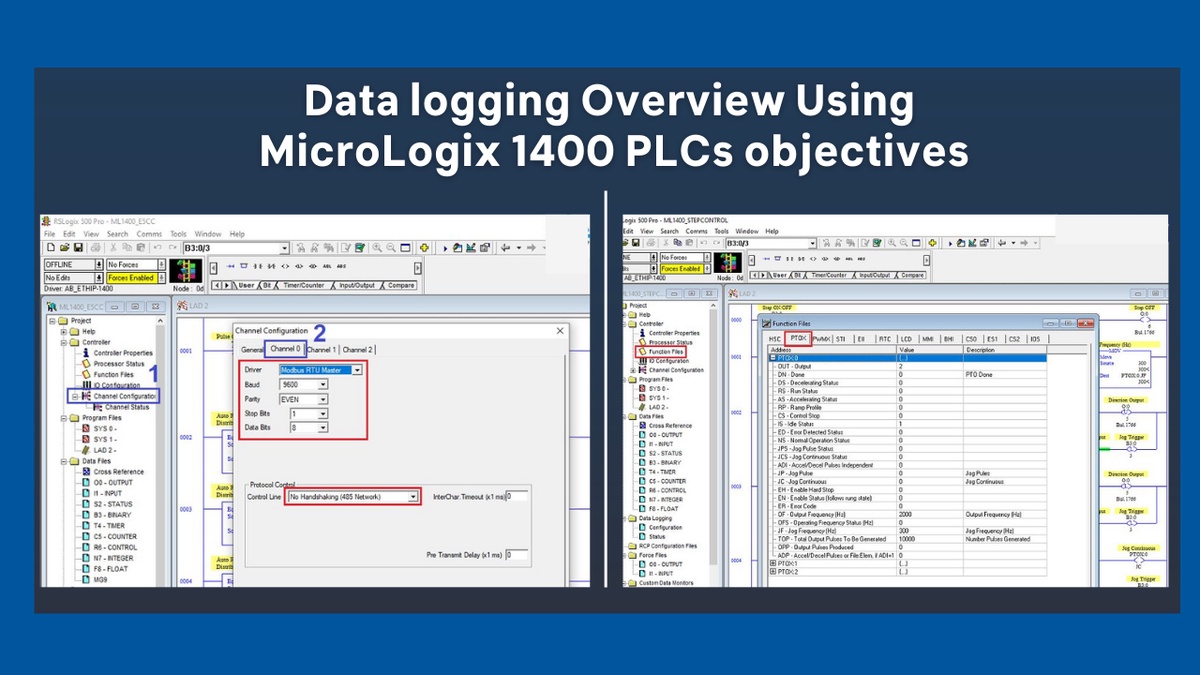

Before activating the data logging feature of the Rockwell Automation MicroLogix 1400 PLC, engineers and technicians must set the logging parameters using the RSLogix 500 software. During the configuration procedure, the kind of data recording, the interval, the duration, and the data to be logged are all provided.

Understanding data logging with the MicroLogix 1400 PLC is necessary for engineers and technicians that work with industrial automation systems. They are able to effectively monitor and maximise the effectiveness of industrial gear and processes by collecting and assessing data.

can be used to increase the efficiency of the equipment or process being observed.

How to Data Logging with MicroLogix 1400 PLCs :

Continuously gathering and preserving data for further analysis and review is known as data logging. In industrial settings, data logging can be used to monitor and enhance the operation of equipment and processes. A popular programmable logic controller used in industrial automation is the MicroLogix 1400 PLC. It can collect and analyse data from a variety of sensors and devices because to its data recording capabilities.

The steps below can be used to implement data logging with a MicroLogix 1400 PLC:

- Configure the Data Logging Parameters:

Use the RSLogix 500 programme to configure the data logging parameters. This involves specifying the information to be logged, the frequency, the duration, and the type of information to be logged (cyclic, event-based, or change-of-state). Configuring the data logging parameters is the first step in establishing data logging with a MicroLogix 1400 PLC.

- With the RSLogix 500 programme, you can start a new project or open an existing one.

- Navigate there to launch the Data Logging Configuration dialogue box.

- Choose the type of data logging to use (cyclic, event-based, or change-of-state) depending on the specific requirements of the application.

- Choose the interval at which the data will be logged, or how frequently.

- It is necessary to specify the length of time for which the data will be logged.

- Choose the data that will be logged. This may include any supported data type by the MicroLogix 1400 PLC, including analogue and digital data.

- After being saved, the data recording configuration must be downloaded to the MicroLogix 1400 PLC.

- Connect Sensors and Devices:

Connect the sensors and machinery whose data needs to be logged to the appropriate input channels on the MicroLogix 1400 PLC.

- Create a Data Table:

Create a data table in the RSLogix 500 programme to save the logged data. When building this data table, it is important to consider the size and type of the data that will be logged.

- Create a Ladder Logic Program:

Create a ladder logic programme in the RSLogix 500 programme that receives sensor data and outputs it to the data table. This software should be set to run continuously with the data logging option enabled.

Also Read :- Rockwell Automation 1766-L32BXBA MicroLogix 1400 PLC

- Configure the Data Logging Feature:

Configure the data recording feature of the MicroLogix 1400 PLC to start logging data at the predetermined interval and for the predetermined period of time. This can be done using the configuration software provided by the vendor.

- Monitor Data Logging:

Keep an eye on the data logging process to ensure that the logged data is being stored in the data table. For this, you can utilise the RSLogix 500 programme or direct access to the PLC's data table.

- Analyze the Logged Data:

Utilise professional analytic programmes or programmes like Microsoft Excel to analyse the recorded data. By using this data to identify trends and patterns in the data, the performance of the equipment or process being monitored can be enhanced.

It is essential to keep in mind that data recording settings like logging interval, length, and data to be logged should be carefully chosen in order to ensure that the data collected is relevant to the industrial process being monitored. It's also crucial to regularly examine and analyse the logged data in order to spot trends and patterns that could be used to improve the performance of the equipment or process being monitored.

It is possible to install data recording and use the logged data to improve the performance of industrial machinery and processes using a MicroLogix 1400 PLC and these techniques. It is essential to regularly assess and study the logged data to ensure that it is still relevant and useful for ongoing optimisation efforts.

The newest provider of automation parts and components is Asteam Techno Solutions Pvt. Ltd. In order to make your job easier, we function as a middleman between the manufacturers and you. We conduct business with several producers, including the most well-known names in the industry as Allen Bradley, Phoenix Contact, Moxa, Schneider Electrics, Omron, Siemens, Vipa, and many others. We are prepared to offer the best and highest-quality industrial replacement parts. Do not be hesitant to get in touch with us; all you need to do is send us an email once you have the part's code. We have a very broad selection and can provide practically all brands. Our consumers may expect us to provide them with low rates and prompt deliveries. Get in touch with us to learn more.

No comments yet