Spot drilling is a crucial step in many machining operations. It is used to create a small indentation in the workpiece to guide the drill bit during subsequent drilling. Spot drills are typically made from high-speed steel (HSS), but in recent years, carbide has become an increasingly popular material choice.

Carbide is a composite material made up of tungsten carbide particles and a metallic binder. It is known for its exceptional hardness, wear resistance, and high melting point. Let’s explore what makes carbide a good material for spot drills and how it can improve drilling performance.

Let’s explore what makes carbide a good material for spot drills and how it can improve drilling performance.

What is Carbide?

Carbide is a composite material made up of tungsten carbide particles and a metallic binder, typically cobalt or nickel. Tungsten carbide is an incredibly hard and wear-resistant material, making it ideal for use in cutting tools.

The metallic binder helps to hold the tungsten carbide particles together and provide additional toughness and durability.

Advantages of Carbide for Spot Drills

Spot drills made with carbide have several advantages over traditional high-speed steel spot drills. Some of the key advantages include:

Hardness

Carbide is significantly harder than HSS, which means it can maintain its cutting edge for longer. This results in less downtime for tool changes and improved overall drilling performance. Since Carbide is harder, it can maintain its cutting edge for longer.

This results in less downtime for tool changes and improved overall drilling performance.

Wear resistance

Carbide is more wear-resistant than HSS, which means it can withstand higher speeds and feeds without dulling or chipping. This results in faster drilling times and improved productivity.

Heat resistance

Carbide has a high melting point of around 2,870°C, making it suitable for use at high temperatures. This means it can handle high-speed drilling without degrading or melting.

Low coefficient of thermal expansion

Carbide has a low coefficient of thermal expansion, which means it does not expand or contract significantly with temperature changes. This allows for more precise and accurate drilling.

Improved surface finish

Because carbide maintains its cutting edge for longer and is more wear-resistant than HSS, it can produce a smoother and more precise finish on the workpiece.

Types of Carbide Spot Drills

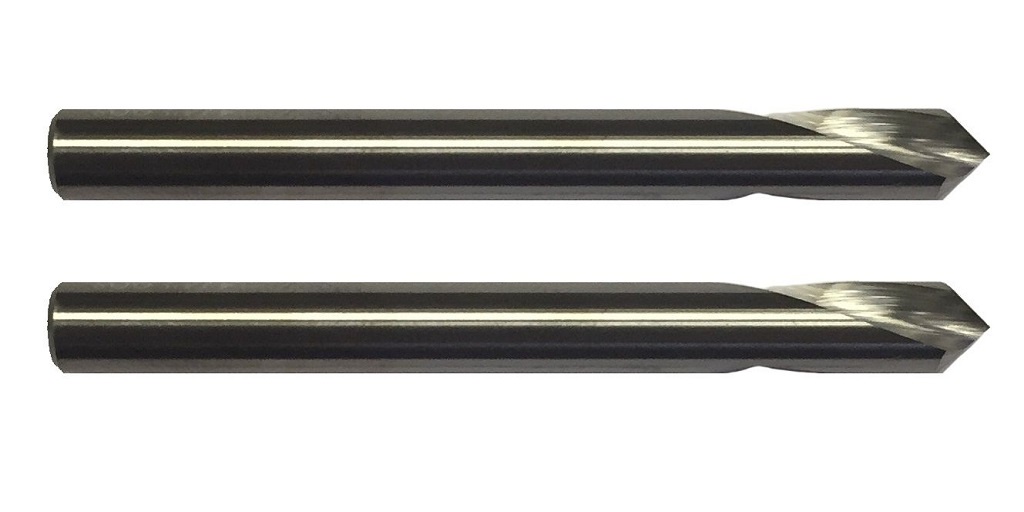

Spot drills in carbide come in various types, each with different features and benefits. Here are some of the most common types of carbide spot drills:

Single margin spot drills

These are the most common type of carbide spot drill and are designed to create precise center holes in workpieces. They have a single cutting edge and a straight shank, and are suitable for use on a variety of materials.

Double margin spot drills

These spot drills of carbide have two cutting edges that help to increase stability and reduce chatter during drilling. They are ideal for use on softer materials, such as aluminum, brass, and plastics.

Spotting and centering drills

These are designed to perform two functions - spotting and centering. They have a pointed tip that creates a small indentation in the workpiece, which helps to guide the drill bit and prevent it from wandering.

90-degree spot drills

These carbide spot drills have a 90-degree angle on the tip, which makes them ideal for creating countersink holes. They are commonly used in the aerospace industry for drilling holes in aircraft structures.

Pilot spot drills

These carbide spot drills have a short shank and a small diameter tip, which makes them ideal for creating small pilot holes in workpieces. They are commonly used in precision drilling applications.

Coolant-fed spot drills

These drills have internal coolant channels that allow coolant to flow directly to the cutting edge. This helps to reduce heat buildup and increase cutting speeds, making them ideal for use in difficult-to-machine materials.

Carbide is a popular material for spot drills due to its many advantages. It is an extremely hard and durable material that can withstand high temperatures and wear, making it ideal for use in high-speed drilling applications.

Overall, the use of carbide spot drills is a smart choice for anyone looking for an efficient and effective drilling solution.

For More Information about End Mills For Aluminum and Stub Drills Please Visit : Online Carbide

No comments yet