The current top grade on the ingress protection (IP) scale is IP69K. A worldwide system known as the IP scale rates products according to how well they can tolerate the entrance of particles and liquids.

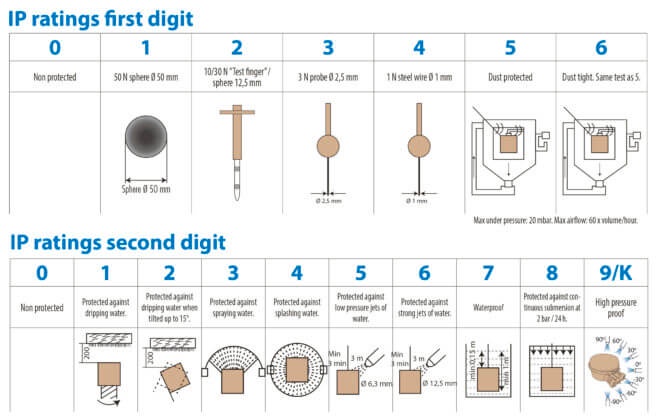

A product's level of dustproof ness is indicated by the first number in the rating, which ranges from 0 to 6. A product's watertightness is indicated by the second number, which ranges from 0 to 9. A "K" is added after the second digit to denote particular high-pressure jet protection. These ratings enable a business to select machinery with the appropriate level of protection for a particular setting.

An item is totally dustproof if it has the IP69K designation, which also means that it can handle washdown pressures of 80 to 100 bar/1,160 to 1,450 PSI, phases of 14 to 16 l/min, and temperatures of up to 176°F/80°C.

In actuality, that means high-pressure jets can spray hot water at a piece of industrial machinery without it suffering any harm.

KPI screen enclosures and other IP69K enclosures are perfect for use in facilities that follow rigorous washdown processes to adhere to high levels of sanitation.

1) Manufacturers Can Meet Standards With IP69K Enclosures:

One in six Americans, or roughly 48 million people, contract a foodborne illness each year, according to the U.S. Food & Drug Administration. 1 The Food Safety Modernization Act was created in response and lays out strict guidelines designed to prevent contamination at every point in the food chain.

In order to achieve these increasingly demanding criteria, makers of food and pharmaceuticals need IP69K equipment. High-pressure jets can easily clear away debris from IP69K items, which are also easily disinfected thanks to the high temperature.

The food-grade (316) stainless steel used in many IP69K items, such as shop-floor display board enclosures, is used in these products. Manufacturers can be more confident in the cleanliness of their facility thanks to this material's corrosion resistance and antibacterial properties.

2) Boosting Of IP69K Enclosures:

Electrical equipment can be installed almost anywhere that is severe thanks to the IP69K grade. It is possible to place equipment precisely where operators need it, which enhances workflow and reduces waiting time.

For instance, stainless-steel computer enclosures enable employees to use PCs right on the production floor, saving them time from having to trek to an office. Similar to this, facilities can install KPI screens in washdown areas using IP69K display enclosures. These displays enhance communication among workers on the manufacturing floor and provide them with current measurements that enable them to fulfill their goals.

3) IP69K Enclosures Reduces Downtime:

In challenging environments, IP69K enclosures are incredibly reliable. Greater assurance that manufacturing can run continuously and without interruption as a result.

Additionally, IP69K enclosures permit manufacturers to employ any equipment they choose. For instance, almost any VESA-compatible screen of a specific size can be housed in an IP69K sanitary TV enclosure. Users may quickly remove, fix, and replace the display without the need for a qualified engineer because of the screen's easy access. Faster repairs and maximum uptime result from this.

No comments yet