Introduction

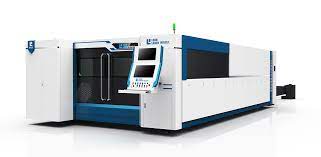

High-power laser cutters have emerged as game-changers in the field of industrial manufacturing. These advanced machines utilize intense beams of coherent light to cut through a wide range of materials with unparalleled precision and speed. This article delves into the world of high power laser cutter exploring their principles, applications, and the transformative impact they have on modern manufacturing processes.

I. Principles of High Power Laser Cutting

A. Basics of Laser Technology

Laser stands for Light Amplification by Stimulated Emission of Radiation.

High-power lasers generate a focused beam of coherent light using powerful amplification mechanisms.

The intense energy in the laser beam allows for efficient material removal through various processes.

B. Laser Generation and Amplification

High-power lasers often employ solid-state, gas, or fiber-based technologies for generating and amplifying laser beams.

The amplification process increases the energy density of the laser beam, enabling it to cut through dense materials.

C. Beam Focusing and Control

High-power laser cutters use specialized optics to focus the laser beam into a small, intense spot on the material's surface.

Computer numerical control (CNC) systems precisely guide the laser beam's movements for accurate cutting.

II. Applications of High Power Laser Cutting

A. Metal Fabrication and Manufacturing

Cutting and shaping of various metals, including steel, aluminum, and titanium, for automotive, aerospace, and industrial applications.

High-power lasers are used in processes like laser welding, drilling, and additive manufacturing.

B. Precision Engineering and Tooling

Creating intricate parts and components with tight tolerances for industries like medical devices, electronics, and microengineering.

Prototyping and production of specialized tooling for high-precision applications.

C. Construction and Architecture

High-power lasers are used for precise cutting and shaping of construction materials like steel beams, concrete, and composite panels.

Intricate architectural details and decorative elements can be produced with high precision.

D. Electronics and Semiconductor Manufacturing

Laser cutting and drilling of circuit boards, semiconductor wafers, and microelectronics components.

High-power lasers play a critical role in producing miniaturized electronic devices.

III. Advantages of High Power Laser Cutting

A. Unparalleled Precision and Accuracy

High-power laser cutters can achieve micron-level precision, ensuring intricate designs and tight tolerances are faithfully reproduced.

B. High Processing Speeds

The intense energy output of high-power lasers allows for rapid material removal, resulting in increased production efficiency.

C. Minimal Material Waste

Non-contact laser cutting minimizes material wastage, making it a more environmentally sustainable option compared to traditional machining methods.

D. Versatility in Material Types and Thicknesses

High-power lasers can cut through a wide range of materials, from metals to plastics, ceramics, and composites, with varying thicknesses.

E. Reduced Thermal Distortion

The localized application of energy in high-power laser cutting leads to a smaller heat-affected zone, minimizing distortion and preserving material properties.

IV. Considerations and Challenges

A. Safety Measures and Regulations

High-power laser cutters require specialized safety measures to protect operators from potentially harmful laser radiation.

B. Maintenance and Operating Costs

High-power laser cutters are sophisticated machines that require regular maintenance and may have higher initial acquisition costs.

C. Material Compatibility and Reflectivity

Some materials may have properties that affect laser absorption, requiring adjustments in laser parameters or additional surface treatments.

V. Future Trends in High Power Laser Cutting

A. Advancements in Laser Technology

Continued research and development aim to enhance laser power and beam quality, enabling even more precise and efficient cutting processes.

B. Integration of AI and Automation

The incorporation of artificial intelligence and automation in high-power laser cutting systems is expected to further optimize processes and increase productivity.

C. Green Laser Technology

Efforts are underway to develop energy-efficient and environmentally-friendly laser technologies, reducing the ecological footprint of high-power laser cutting.

Conclusion

High-power laser cutters represent a technological leap forward in modern manufacturing. Their unparalleled precision, speed, and versatility have revolutionized industries ranging from aerospace to electronics. As research and development in laser technology continue, we can anticipate further refinements and innovations in high-power laser cutting, driving continued growth and innovation in industrial manufacturing processes.

No comments yet