How to Fusion Splice Fiber?

Using the fusion splice process to join two fibers is a simple process, but you will need to ensure that your splice is accurate. Use an optical time domain reflectometer (OTDR) to measure the loss. Then, align and melt the fibers, and protect the splice joint with a heat shrink tube.

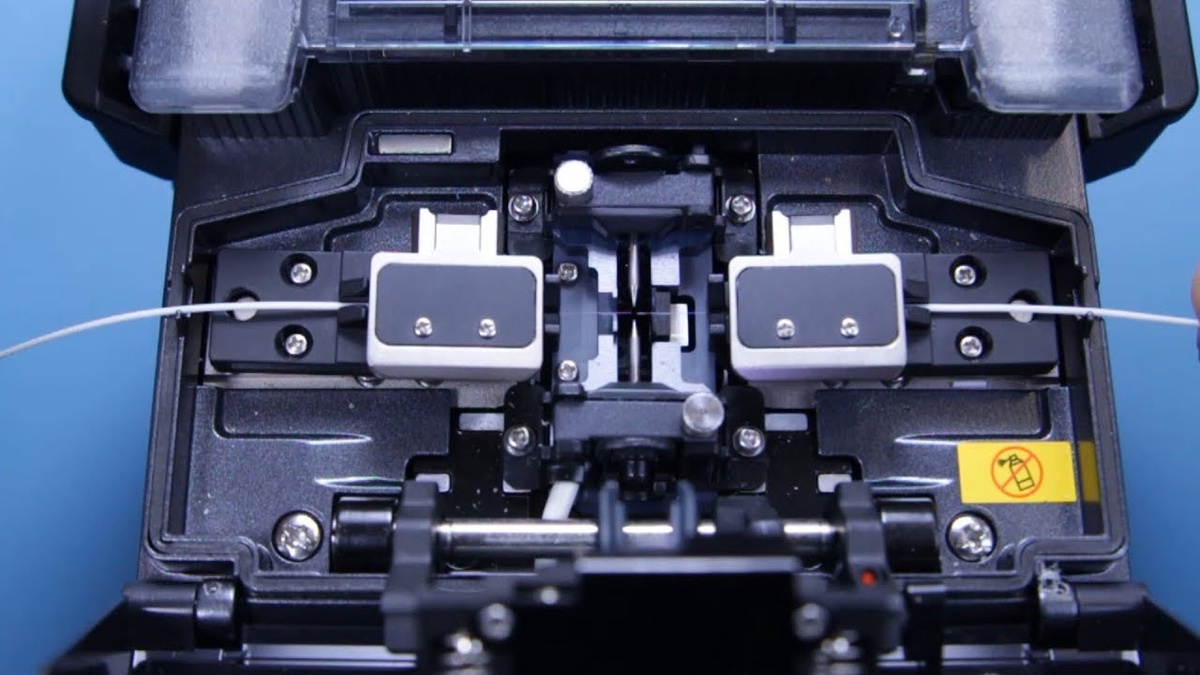

Align and melt fibers

Optical fibers are heated and melted in fusion splicing. In the process, the splicing ends are pressed and aligned. The ends are also polished to obtain a mirror-smooth surface.

The self-alignment ratio is a measurement of the amount of E by which the fiber offset D decreases. In fusion splicing, the ratio is calculated during test discharge before the fusion splicing operation. The purpose of this measurement is to provide a method of compensation for the offset.

The fusion splicing apparatus is expensive and requires a lot of training. However, the results of Fusion Splicer are generally good. This process requires careful handling, and a clean environment is essential. Fusion splices are very stable, and will not break during normal handling.

To achieve the most accurate splice, you will need an excellent flash welding knife. The cost is approximately $1,000 to $3,000. A flash welding knife can produce a cutting angle of 0.5 degrees. You will also need to have a good fiber cleaver to minimize light loss.

A good fiber cleaver should not only be smooth, but also perpendicular to the fiber axis. You will also need a mirror-smooth cut end. You will also need to remove any jackets, coatings, or other layers of material from the fiber ends.

image source: https://www.pinterest.ph

Protect the splice joint with a heat shrink tube

Using a heat shrink tube when fusion splicing fiber is important to protect the splice joint. The splice joint needs to be protected from excessive bending forces. This is especially important for fusion splices, which use an electrical arc to join two fiber ends together.

The heat shrink tube protects the splice joint by shrinking into a tube that wraps the fiber joint. It also provides physical protection to the spliced joint. The tube is made from cross-linked polyolefin and includes a steel strength member.

The strength member should be installed first in the target holder position. Then the fibers should be slid onto the sleeve. The fibers should be placed into V-grooves. This will prevent fibers from twisting.

Once the fibers are installed, the splice sleeve holding apparatus is then used to hold the fibers in place. This prevents contact and allows for easy removal of the splice sleeve.

The strength member is made from stainless steel, non-metallic materials, or silicone. The Fiber Multimeter should never be installed before the strength member is installed. This ensures a solid fiber joint.

The splice sleeve should be installed in a splice holder, where it can be inspected for air bubbles and punctures. If air bubbles are present, they can cause the sleeve to split. The sleeves should also have uniform tension. If there is too much tension, it may cause the fiber to break.

image source: https://www.pinterest.ph

Verify the splice loss with an optical time domain reflectometer (OTDR)

Optical time domain reflectometers (OTDRs) are extremely useful test instruments for fiber optic systems. They can verify the loss of a splice and help detect problems during installation or troubleshooting.

OTDRs use a system similar to radar sets to calculate the amount of light reflected from a connector. The instrument sends a light pulse into the fiber and measures the amount of light reflected back. This information is used to calculate the loss.

OTDRs can be used to measure the overall loss of a optical fiber identifier system, point losses caused by splicing, and individual connectors. They also provide data in real time. The instrument's output can be stored on internal memory and sent to a computer for downloading. These measurements can be used to determine the best compromise between noise and resoluton.

An OTDR is essential for short-reach single-mode applications. They are also useful in determining the location of faults in a fiber optic system. They can also be used to measure the length of a cable or to identify bent sections.

OTDRs can be used for splice loss verification, but you must be careful when using them. Some connectors, particularly fusion splices, can reduce transmitted power on the fiber.

When measuring splice loss, you will need markers close to the splice. To get accurate measurements, you must use two markers that are roughly the same distance from the splice.

No comments yet