The use of a laser beam to etch a design onto a solid substance (such as glass, wood, or metal) is known as laser etching. For permanent cuts, the amount of heat needed varies from material to material, and most lasers can be adjusted accordingly. The cutting procedure can be performed by either hand-held lasers or machine-operated lenses, both of which are often used by manufacturers. Technicians frequently employ portable lasers to address small defects and improve product quality. Craftspeople and engravers can also use portable lasers to do detailed work on surfaces that aren't too big. Learn more about the features and benefits of laser etching machines by reading this review.

Types of Laser Etching Machines

Laser etching and engraving are both types of laser etching machines. The difference between the two is how deep the laser goes into the material.

Laser engraving: It can take several passes, and takes longer than laser etching. Larger laser powers can increase speed, but you probably won't need more than 100W for etching.

Laser etching machine: This could save you time and money if you want to make long-lasting product labels, mark your items without worrying about your logo fading, or make high-quality workplace signs.

How Does Laser Marking Work

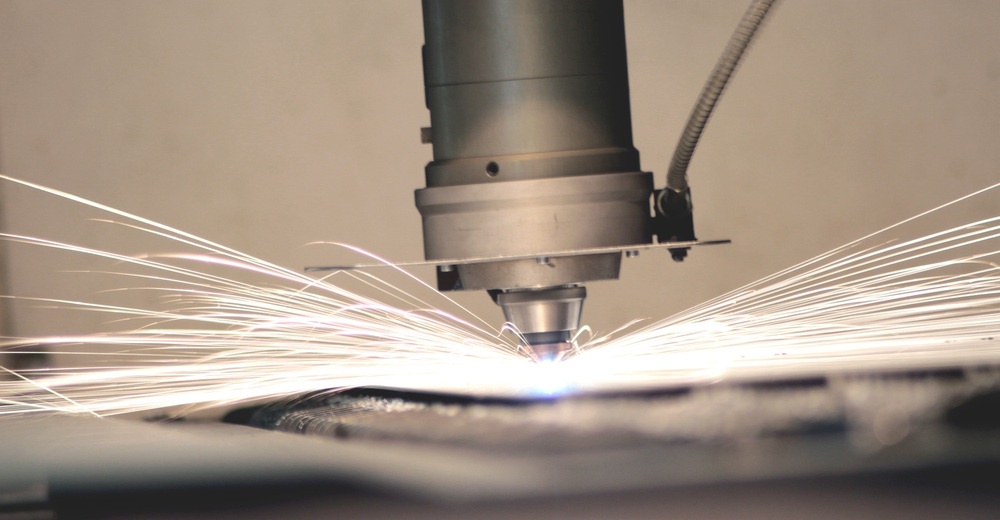

Laser marking uses a concentrated beam of light to mark the surface of a material. When the beam strikes a surface, it changes the material's characteristics and appearance. The laser marking machine's pinpoint accuracy and high-contrast, long-lasting marks are suitable for almost any material because the beam is focused on a small area. Because of this, laser marking is ideal for applications requiring precision and durability.

How Can a Laser Machine Make a Mark?

The machine can etch characters, numbers, signs, pictures, codes, and more in a wide range of sizes and shapes. Uses abound for these printed patterns:

- A means of identifying the original manufacturer and protecting against counterfeits (logo, brand name, copyright)

- Measurements, such as circumference, are useful for end-users and consumers.

- Information about a product's location and how to track it, such as a serial number, release date, and different graphic and numeric codes

- Details that show the product meets or exceeds the market's established quality standards

- Individualization of the goods

Each type of laser etching machine is best suited for use with a certain type of surface.

Benefits of Laser Etching

Precision

Depending on the model, a high-quality laser marking machine can perfectly etch a broad range of materials, from metal and wood to foam, leather, porcelain, and even cloth, allowing you to fulfil virtually any design request. The beam's non-contact nature means it solely impacts the region being heated, sparing the surrounding area from abrasions and other harm. So, you can be sure that the final product won't have any mistakes and will be the best it can be.

Elevate safety

Using a laser to make a mark is a risk-free method. This is the primary motivator for many businesses to purchase such equipment. You can make the workplace safer for employees quickly, especially if everyone on the team knows how to use the equipment correctly and is aware of any extra safety measures that need to be taken when working with certain materials.

Increased Development Speed

The time and effort needed to complete a project can be reduced by using laser etching machines instead of laborious manual methods. As a result, both productivity and hourly profits go up, lead times go down, capacity goes up, competitiveness goes up, and a lot of money is saved.

With laser and computer technology, the user can simply change the design at any time, boosting manufacturing flexibility. A laser etching machine is a great bargain for start-up firms, hobbyists, and educational institutions. It can etch jewelry, architectural models, and educational and craft projects.

The Laser Etching Machine Buying Guide

You should think about both the pricing and the features of laser etching machines before making a purchase. Make sure the machine gets hot enough and has enough power to cut the material you intend to use.

Prices for laser etching machines can range from quite low to quite high, depending on the machine's specific capabilities and features. There is no need to invest in a top-of-the-line laser etching machine if you just plan on using it sometimes. In the event that you won't be the one to operate the laser etching equipment, feel free to consult with ThunderLaser for advice. Doing so will ensure that the final product is a functional machine that can fulfill your requirements.

No comments yet