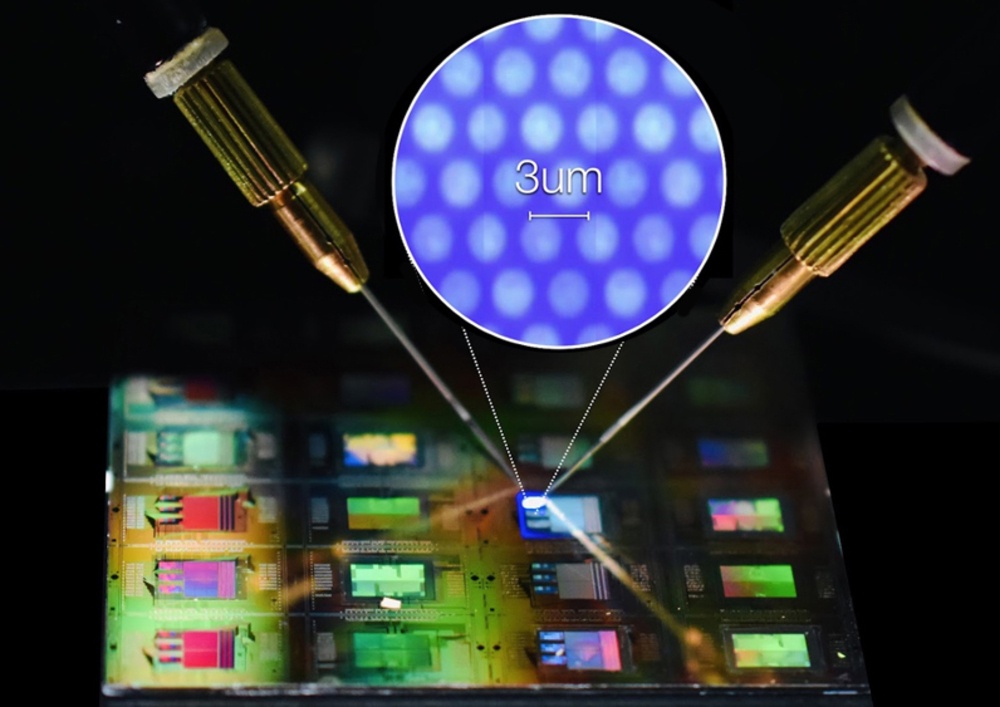

MICLEDI Microdisplays is an ingenious technology firm developing microLED displays designed to make use of the latest Gen. AR Glasses Technology and has demonstrated the first array of microLEDs designed for AR built on a 300 mm CMOS manufacturing platform.

MicroLED is a groundbreaking technological advancement in the screen that claims bright and high contrast while cutting down on power consumption. These features are particularly important for augmented reality (AR) and virtual reality (VR) applications, which offer the most immersive and immersive experience for the user.

The features of technology in the most current product are:

-

CMOS-fab-compatible RGB epitaxial material that has been reconstructed onto 300 mm CMOS wafers, which are integrated into the latest CMOS backplane ASICs through hybrid bonding W2W.

-

Pixel-level Fresnel beam shape of the lens for High-Efficiency Waveguide integration.

-

MicroLED technology is designed specifically for industry-standard tooling and manufacturing processes that are employed to produce large quantities for CMOS foundries. CMOS foundries.

(Enclosed microLED dies with test arrays)

AR headsets are currently heavy and heavy. The quality of the images is not at excellent resolution and the headsets cost a lot. Nearly every major tech company spends money on AR to influence the future of its consumer products. According to a research company Yole Development, the demand for displays with microdisplays AR headsets is predicted to rise at a rate higher than 100 percent, increasing to more than $1.8B by 2025, and then more than $4.9B in 2027.

About MICLEDI

MICLEDI Microdisplays is a fabless manufacturer of microLED displays aimed towards the Augmented Reality (AR) market. MicroLEDI's technology relies on an innovative mix of III/V material processing 3-D integration, as well as 300mm CMOS ASIC Backplane technology which is joined wafer-to-wafer to create an independent compact monolithic AR display that has high-quality images and high energy efficiency. The process of technology, as well as the prototyping, is being improved together with IMEC and then transferred to the industrial partners to make it possible to manufacture in bulk. MIC LED is supported by Flanders Innovation and Entrepreneurship (VLAIO).

No comments yet