Introduction:

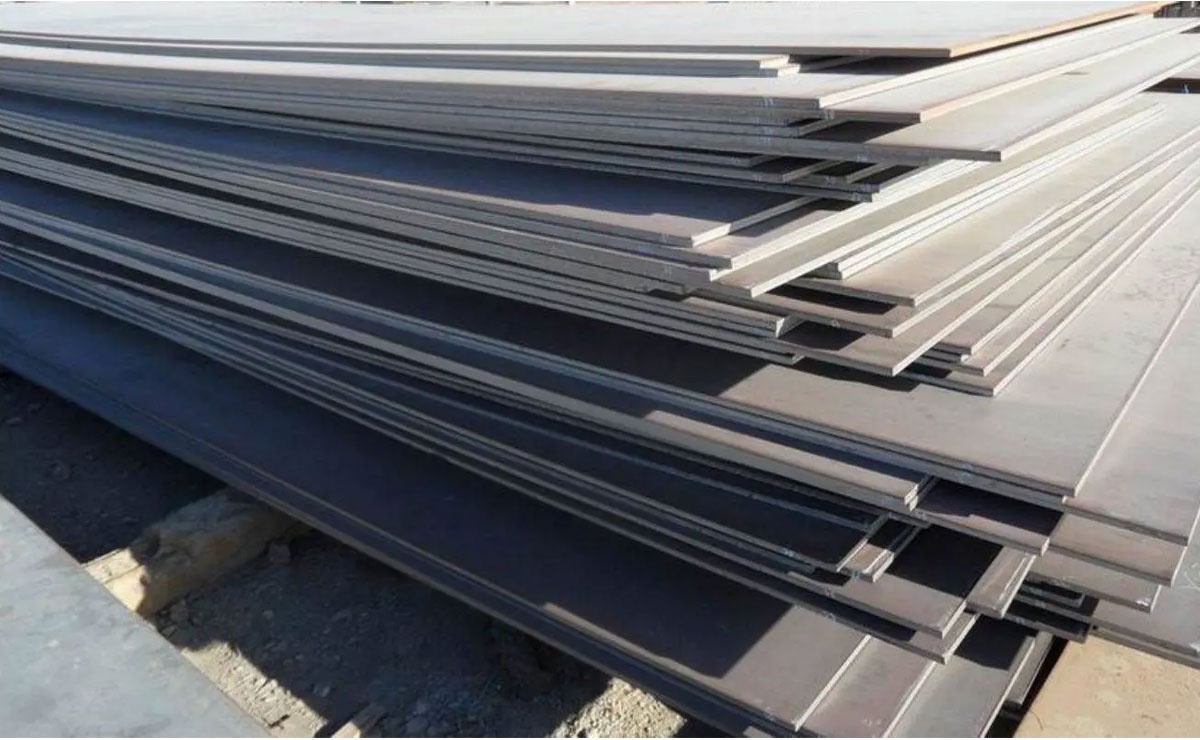

MS Sheets have become indispensable in various industries, playing a crucial role in construction, manufacturing, automotive, and beyond. One of the most widely used types of metal sheets is Mild Steel (MS) sheets. In this comprehensive guide, we'll delve into the world of MS sheets, exploring their properties, applications, and the reasons behind their widespread popularity.

Understanding MS Sheets:

1. Composition and Properties:

Mild Steel, also known as low carbon steel, is primarily composed of iron and a small percentage of carbon. This composition provides MS sheets with unique characteristics such as ductility, weldability, and versatility. MS sheets typically have a carbon content ranging from 0.05% to 0.25%, making them suitable for a wide range of applications.

2. Types of MS Sheets:

MS sheets come in various types, including hot-rolled, cold-rolled, and galvanized sheets. Hot-rolled MS sheets are produced at high temperatures, making them ideal for structural applications. Cold-rolled sheets undergo processing at lower temperatures, resulting in smoother surfaces and tighter tolerances. Galvanized sheets are coated with a layer of zinc to enhance corrosion resistance.

Applications of MS Sheets:

1. Construction Industry:

MS sheets find extensive use in the construction sector for manufacturing beams, columns, and other structural elements. Their high strength and durability make them an excellent choice for building frameworks.

2. Automotive Manufacturing:

In the automotive industry, MS sheets are employed to fabricate various components, including car bodies, chassis, and panels. Their formability and weldability contribute to the efficiency of manufacturing processes.

3. Fabrication and General Engineering:

MS sheets are widely used in fabrication and general engineering due to their versatility. From creating machine parts to manufacturing everyday items, the adaptability of MS sheets makes them a preferred material.

Advantages of MS Sheets:

1. Cost-Effective:

Mild Steel is relatively inexpensive compared to other types of steel, making MS sheets a cost-effective choice for many applications.

2. Formability and Weldability:

MS sheets are known for their excellent formability, allowing for easy shaping and fabrication. Additionally, they are highly weldable, making them suitable for various joining techniques.

3. Strength and Durability:

With adequate strength and durability, MS sheets offer reliable performance in diverse conditions. This makes them suitable for both indoor and outdoor applications.

Conclusion:

MS Sheets are an integral part of numerous industries, contributing to the creation of structures, vehicles, and everyday products. Their versatile nature, coupled with cost-effectiveness and desirable properties, has solidified their position as a preferred material in the world of metal fabrication. As technology advances, the applications and innovations surrounding MS sheets are likely to expand, further showcasing the enduring significance of this humble yet robust material.

No comments yet