In today's fast-paced manufacturing environment, ensuring the quality and durability of packaging materials is paramount. Among the various tests conducted to assess packaging strength, the box compression tester stands out as a crucial step. With the advent of technology, traditional manual testing methods have evolved into computerised systems, offering enhanced accuracy and efficiency.

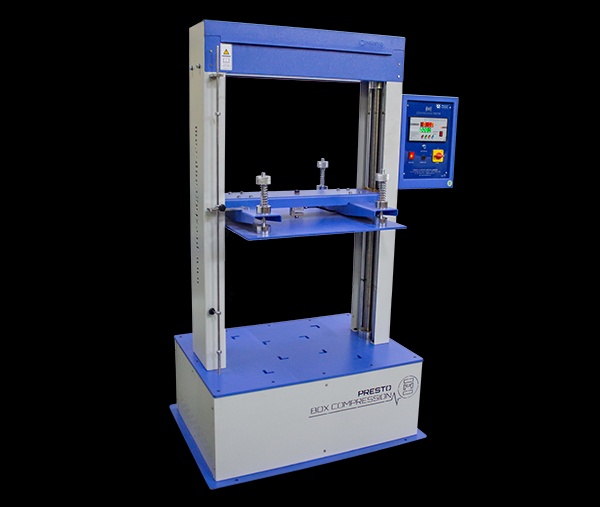

A box compression tester computerised serves as a vital tool in evaluating the structural integrity of packaging materials, particularly corrugated boxes. By subjecting the boxes to controlled compressive forces, manufacturers can simulate real-world scenarios, such as stacking during storage or transportation, to determine their load-bearing capacity. In essence, this test aids in identifying potential weaknesses in packaging design or materials, thereby facilitating improvements to enhance product protection and minimise risks of damage or breakage.

In conclusion, computerised box compression testers represent a significant advancement in packaging quality assurance practices. By leveraging technology to automate testing processes and enhance data analysis capabilities, manufacturers can effectively identify and address potential vulnerabilities in packaging materials. Ultimately, investing in a reliable and efficient box compression tester manufacturer is not only a sound business decision but also a testament to a commitment to delivering superior products to consumers.

No comments yet