The Amazing World of Plastic Injection Molding

Plastic injection molding is a procedure employed to make parts being synthetic huge amounts. Various businesses need synthetic injection molding to make their products or services as it provides benefits.

Advantages – Plastic injection molding delivers a few advantages like low work costs, high manufacturing cost, and uniformity in quality. For the reason why the strategy involves a device or gear that will do the thing which is same and regularly.

Innovation – Tech has improved the procedure, making this more efficient and effective. Innovations like 3D publishing are to be able to create molds which can be complex higher precision.

Safety – Many services and products require strict protection standards, offers the benefit of creating elements that meet regulatory requirements. The technique helps make certain that no contaminants exist into the item used to produce these products.

Use – In the industry which is automotive such as for example dashboard panels, door handles, along with other synthetic elements, are manufactured that way. Likewise, the customer services and products sector also relies heavily with this procedure to make toys, activities gear, along with other items that are artificial.

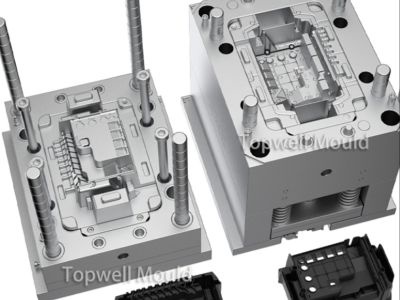

How to utilize – It requires equipment which is specialized the product which is right produce quality products. The strategy involves plastic which is inserting and melting them as a mildew. After the cools that are synthetic the mold is eliminated.

Service – Companies that focus on this process must be sure they provide exemplary service making use of their clients. This might consist of troubleshooting issues, providing design help, and on occasion even providing to help in item selection.

Quality – The quality for the product used, plus the accuracy of this mold design, all may play a role which is significant the typical associated with the product which is finish. Therefore, it is vital to identify a provider which is dependable of injection molding solutions whom prioritize the standard of their work.

Application – It is often used to produce small parts which are synthetic as buttons, as well as larger components like automobile components. The process can also be appropriate making shapes that are complex can be tough to mold by other practices.

Conclusion:

Plastic injection molding is a vital process used in many industries to produce plastic products. Its advantages include high production rates, competitive labor costs, and high quality. The process has undergone significant innovation, adapting to changing technology, and it has been a reliable method for producing quality products consistently. As such, it remains an essential process for the creation of many everyday items.

No comments yet