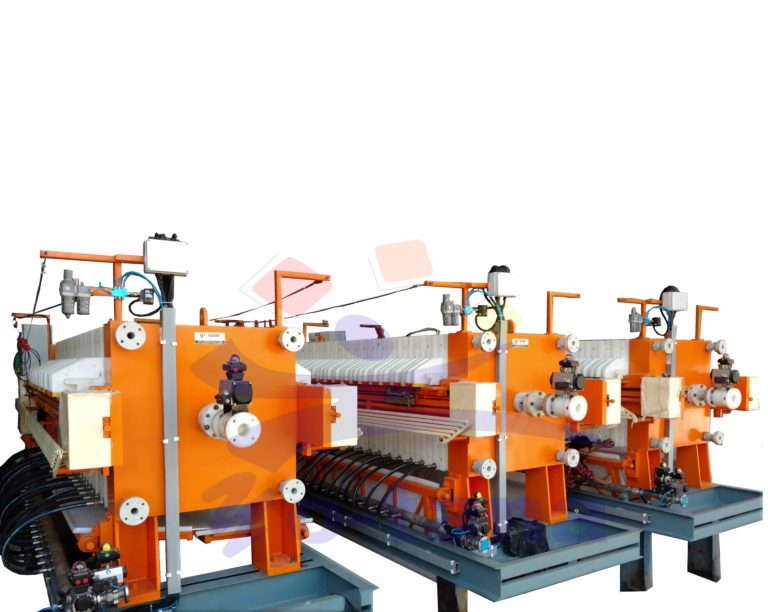

Introduction - In the world of industrial filtration, the membrane filter press stands as an innovative option that revolutionizes the splitting-up procedure. Yo-Tana Machine Tools Pvt.Ltd, based in Ahmedabad, has established itself as a leading manufacturer and supplier of membrane filter presses. In this article, we look into the functionality, advantages, and applications of membrane filter presses, highlighting how Yo-Tana Machine Tools Pvt.Ltd has contributed to their advancement.

Understanding Membrane Filter Press

The membrane filter press contains a collection of chambers, each having filter plates with incorporated membrane layers. These membranes are pumped up using compressed air or hydraulic stress, applying stress on the filter cake to eject the liquid.

Applications of Membrane Filter Presses

Yo-Tana Machine Tools Pvt.Ltd accommodates a variety of industries by using membrane filter presses appropriate for numerous applications.

Chemical Industry - Membrane filter presses efficiently different solids and fluids in chemical manufacturing procedures, such as dyes, pigments, and specialty chemicals.

Pharmaceuticals - The pharmaceutical industry takes advantage of the exact splitting up and premium filtration attained by membrane filter presses throughout drug manufacturing and purification.

Yo-Tana Machine Tools Pvt. Ltd. focuses on technological innovations and client satisfaction, we constantly improve the layout and functionality of our filter presses. Our extensive selection of high-efficiency membrane filter presses is designed to satisfy particular industry demands, guaranteeing dependable and efficient filtration procedures

Throughout membrane filtration, a single feed stream is passed through a membrane layer that serves as a physical barrier, just permitting certain compounds with unique attributes to travel through.

The material that goes through the membrane layer is established by the size and purification media of the membrane. The most common kinds of membrane filtration include microfiltration (MF), ultrafiltration (UF), Nano filtration (NF), and turn-around osmosis (RO).

Exactly how does a filter press job?

Filter press is made use of for the splitting up of strong and liquid impurities. It works on the principle of a slurry-pumped machine. In this case, the strong obtain dispersed throughout the filling of the cycle, and as a result with the help of filter cloth and filter cake, the corner port obtains converted into the manifold.

Filter press is a type of filtration method that needs feed pump pressure. Once the strong begin creating within the chamber, for that reason, the choke which has plenty of solid types the cake. There are certain applications where the membrane filter press works. The filter papers can be constructed utilizing a vast array, of sizes.

The dimensions or abilities with 1500, and 2000 mm filter documents to extract the pollutants of solid right into liquid in a wide range of markets are therefore used. The sectors where these filter paper jobs are food and beverage, chemical manufacturing, power generation steel mill, municipal plant, mining, and so on.

Listed below we'll look at the key benefits of membrane filtration systems for different procedure media.

Benefits of Membrane Filtration Systems

High flexibility: Membrane filtration has a variety of applications, from removing big particulate products to getting rid of liquefied substances. This implies that no matter your separation obstacle or application needs, different membrane filtration products are available to resolve them.

Lower production costs: Unlike other technologies, membrane filtration is generally more economical. This is because of its reduced installment expenses, lower energy expenses, and fewer processing actions. At the same time, it creates a better level of pureness and higher general yields. Membrane filters do not lead to a filter cake, successfully removing prices because of deposit disposal.

No need for chemicals: To address the need for restricting chemical concentrations utilized in water therapy, membrane filtration is an optimum option because it does not require any kind of chemical ingredients. Rather, membrane filtration physically removes pathogens and eliminates the requirement to include chemicals, such as in chlorination.

Removes pathogens: Membrane filtration can eliminate 90% to 100% of microorganisms from the procedure fluid.

Energy efficiency: Membrane filtration has considerably low power requirements. For instance, making use of ultrafiltration before Nano purification and reverse osmosis saves power by 20%.

Keeps proteins intact: Membrane filtration is one of the most effective techniques for separating proteins without denaturing them. Because it does not present chemical reagents or warmth input, membrane filtration preserves the honesty of healthy proteins.

Ideal for testing: Membrane filtration is an effective approach to evaluating liquid samples for different types of contamination. By transferring the membrane filter from one tool to one more, it can separate and mention different microbial nests.

Saves time: When acquiring quantitative information, membrane filtration offers quicker results than the MPN (most potential number) approach. It just takes 1 day for membrane filtration to yield results.

High-quality output: Membrane filtration is a tidy, environment-friendly technology that uses reputable, appropriate results. The separation process is based just on the molecular dimension, eliminating the demand for additives. This results in a high-quality final product, which much more easily abides by the high criteria of customers and the stringent needs of regulatory authorities.

Membrane Filtration Systems from Membrane Layer System Specialists

Membrane filtration is utilized in a wide variety of applications, from milk processing to wastewater therapy to beer brewing. The separation process supplies many advantages, including flexibility, lower power demands, decreased production costs, the capacity to sterilize heat-sensitive materials, and the removal of approximately 100% of microorganisms.

At Yo-Tana Machine Tools Pvt.Ltd, we provide customized membrane filtration systems that meet your distinct application needs.

Conclusion

The membrane filter press has emerged as a game-changer in industrial purification, giving improved effectiveness, boosted cake dampness web content, and greater solids retention. Yo-Tana Machine Tools Pvt. Ltd, based in Ahmedabad, is a leading supplier of advanced membrane filter presses, providing cutting-edge options to a varied range of sectors. By leveraging the advantages of membrane filter presses, Yo-Tana Machine Tools Pvt.Ltd contributes to the optimization of industrial procedures, driving effectiveness and sustainability in filtering procedures.

No comments yet