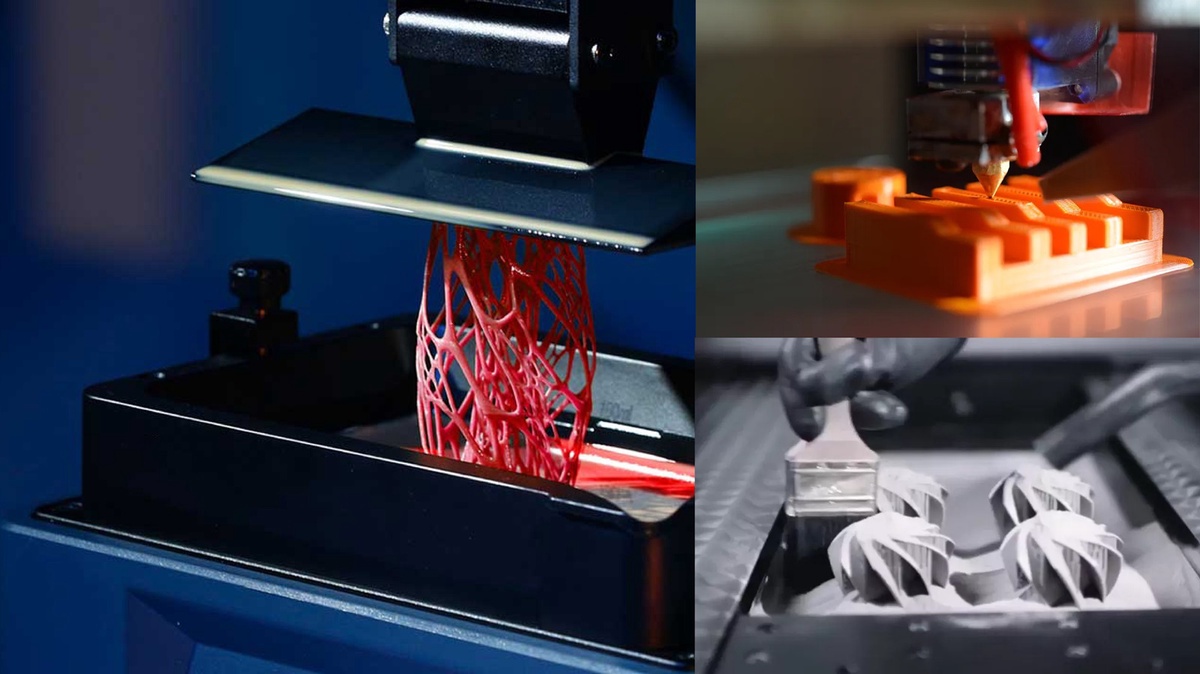

Metal 3D printing technology is revolutionizing manufacturing across various industries in India. This innovative technology allows for the production of complex metal parts with unprecedented precision and efficiency. As a result, several sectors are leveraging metal 3D printing to enhance their operations and drive growth. In this blog, we'll explore seven industries in India that are reaping the benefits of metal 3D printing services, with a focus on the keywords metal 3D printing India and "metal 3D printing service."

- Aerospace and Defense

The aerospace and defense industries in India are embracing metal 3D printing to manufacture lightweight yet robust components for aircraft, missiles, and satellites. Metal 3D printing allows for the creation of complex geometries that were previously difficult or impossible to achieve with traditional manufacturing methods. This technology enables faster prototyping, customization, and cost-effective production of aerospace parts.

- Automotive

In the automotive sector, metal 3D printing is revolutionizing the production of vehicle components, including engine parts, exhaust systems, and lightweight structural components. By utilizing metal 3D printing services, automotive manufacturers in India can reduce lead times, optimize designs for performance and efficiency, and minimize material wastage.

- Healthcare

Metal 3D printing is making significant strides in the healthcare industry, particularly in the production of customized medical implants and prosthetics. In India, hospitals and medical device companies are utilizing metal 3D printing technology to create patient-specific implants, such as hip and knee replacements, dental implants, and cranial implants. This personalized approach improves patient outcomes and reduces the risk of implant rejection.

- Tooling and Machinery

Metal 3D printing is transforming the tooling and machinery sector by enabling the rapid production of complex molds, dies, and machine components. Indian manufacturers are leveraging this technology to enhance productivity, reduce tooling costs, and shorten production cycles. Metal 3D printing also allows for the creation of conformal cooling channels within molds, improving efficiency and quality in plastic injection molding processes.

- Electronics

The electronics industry in India is adopting metal 3D printing for the fabrication of heat sinks, electronic enclosures, and custom components for electronic devices. Metal 3D printing offers the flexibility to produce intricate designs with integrated features, such as cooling channels and electrical pathways. This capability enables electronics manufacturers to optimize thermal management and enhance the performance and reliability of their products.

- Energy

Metal 3D printing is finding applications in the energy sector, particularly in the production of components for renewable energy systems, such as wind turbines and solar panels. Indian energy companies are leveraging this technology to manufacture lightweight, durable parts that withstand harsh environmental conditions. Metal 3D printing also enables the design and production of complex shapes optimized for energy efficiency and performance.

- Jewelry and Fashion

In the jewelry and fashion industry, metal 3D printing is revolutionizing the way custom designs are created and produced. Indian jewelers and fashion designers are using this technology to bring intricate and personalized designs to life, offering customers unique and high-quality pieces. Metal 3D printing allows for the production of lightweight yet durable jewelry and fashion accessories with intricate details and textures.

In conclusion, metal 3D printing technology is driving innovation and transformation across various industries in India. By leveraging metal 3D printing services, companies can enhance their manufacturing capabilities, reduce costs, and bring high-quality products to market faster. As the technology continues to advance, its impact on Indian industries is expected to grow, paving the way for a more efficient and sustainable future.

No comments yet