In the dynamic world of packaging, ensuring that products withstand the rigors of transportation is paramount. Drop testers, specifically designed machines for assessing the impact resistance of packages, play a pivotal role in guaranteeing the robustness of packaging materials. Let's delve into the realm of drop testers, exploring their significance, the technology behind them, and reputable manufacturers in the industry.

- The Significance of Drop Testers

Drop testing is a critical step in the quality assurance process for packaging. It simulates real-world scenarios where packages may be subjected to accidental drops during handling, transportation, or even in a retail setting. By utilising a drop tester, manufacturers can gauge the durability of their packaging, ensuring that products remain intact and undamaged under various impact conditions. This not only safeguards the contents but also enhances customer satisfaction by delivering products in pristine condition.

- The Technology Behind Drop Testers

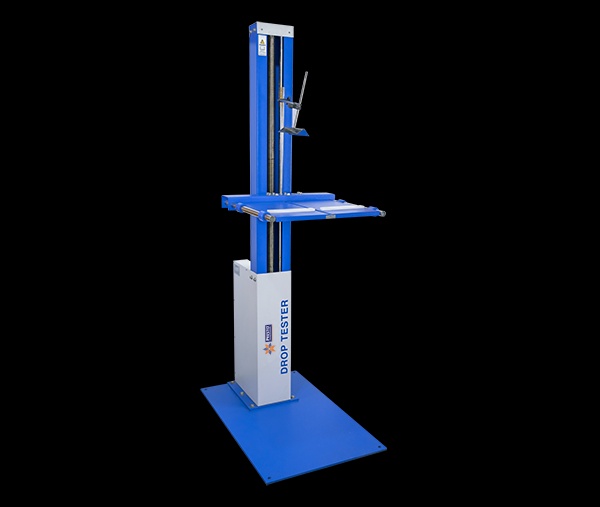

Drop testers are sophisticated machines designed to mimic the forces experienced during a fall. These machines typically consist of a sturdy frame, a mechanism to release the package, and sensors to measure the impact. Controlled drops from specified heights allow for a systematic evaluation of how packaging materials perform under stress. Advanced models may feature programmable settings, allowing for a tailored testing approach to suit diverse packaging requirements.

- Leading Drop Tester Manufacturers

When it comes to investing in a drop tester, opting for a reputable drop tester manufacturer is crucial to ensure accurate and reliable results. One prominent player in the industry is . Renowned for their commitment to innovation and quality, they offer a range of drop testers designed to meet the diverse needs of the packaging industry. With cutting-edge technology and a track record of customer satisfaction, it stands out as a go-to choice for businesses seeking precision in drop testing.

- Unveiling the Drop Tester Machine

The drop tester machine is a testament to engineering excellence. Engineered for precision, durability, and ease of use, their drop testers are equipped with features that make them suitable for a wide range of applications. Whether you are testing fragile electronics, robust industrial components, or delicate consumer goods, drop testers provide the accuracy and repeatability needed for comprehensive quality control.

- Choosing the Right Drop Tester

Investing in a drop tester is an investment in the reliability of your packaging. With commitment to quality, you can trust that their drop tester machine will deliver consistent and accurate results, ensuring that your products reach their destination in optimal condition. Evaluate your specific testing requirements, consider the types of packages you handle, and choose a drop tester manufacturer that aligns with your business needs.

In conclusion, the world of drop testers is one of precision and assurance. With leading the way, businesses can elevate their packaging quality control, ultimately enhancing the resilience of their products in the supply chain. As you embark on the journey to fortify your packaging processes, consider as your trusted partner in ensuring that your packages stand up to the challenges of the real world.

No comments yet