Water meter calibration is a vital process that ensures the accuracy of water measurements, billing, and efficient resource management. With the advent of smart technologies, this field has seen significant advancements that enhance the calibration process and improve the overall reliability of water meters.

Water Meter Calibration- Ensure Accuracy and Fair Billing

Water meters are essential devices used in residential, commercial, industrial, and municipal settings to measure the consumption of water. To ensure fair billing and efficient resource management, it is crucial that these meters provide accurate measurements. Calibration is the process of adjusting and verifying a water meter's accuracy, and it plays a central role in maintaining the reliability of water measurement systems.

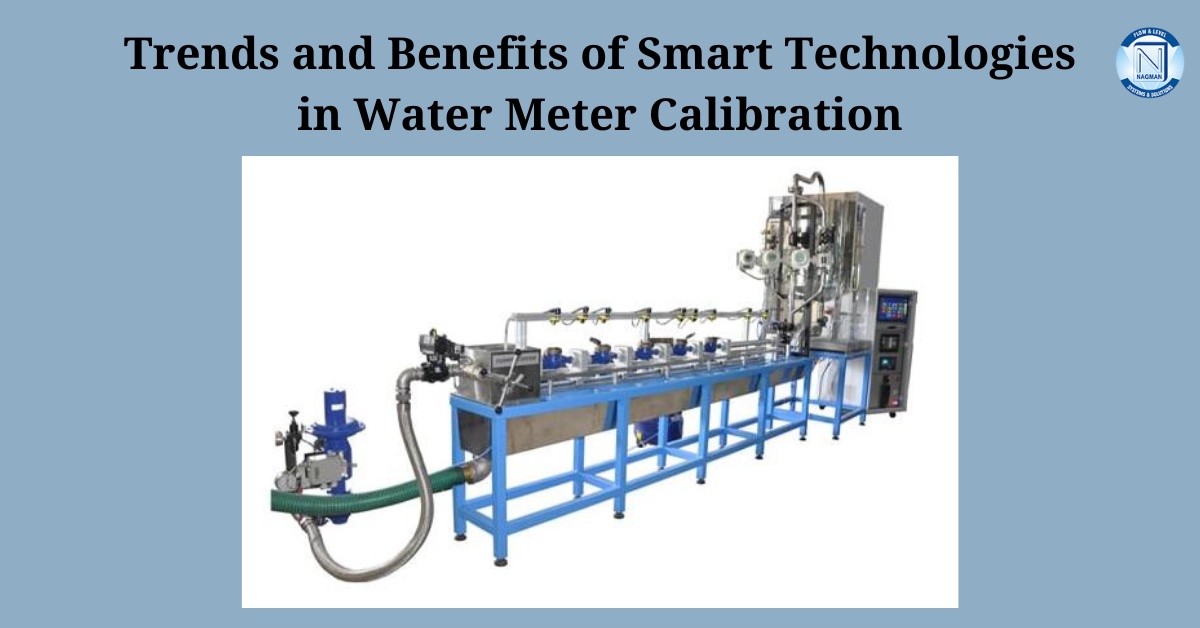

The Significance of Calibration Equipment

Water meter test bench manufacturers, such as test bench producers, are instrumental in ensuring the precision and reliability of water meters. Manufacturers of these systems play a pivotal role in shaping the calibration industry. They design and produce cutting-edge equipment that aligns with the latest industry trends. These advanced solutions are essential to meet the growing demand for highly accurate water meters, especially with the increased focus on water conservation and sustainability.

Portable Water Meter Test Benches - On-the-Go Calibration

Portable water meter test bench units are innovative solutions that cater to the changing needs of the industry. These compact and mobile units offer flexibility and convenience for calibrating water meters at various locations. They are particularly valuable in the field, where traditional fixed calibration setups may not be feasible. **Portable test benches** come equipped with state-of-the-art technology to ensure high-precision calibration, making them indispensable in the calibration process.

Ultrasonic Water Meters in India - The Technological Leap

Ultrasonic water meter India represents a significant technological leap in the field of water metering. These meters utilize ultrasonic waves to measure the flow of water through the pipe. They have gained prominence in India and around the world due to their accuracy, durability, and ability to measure even low flow rates with precision. Ultrasonic water meter manufacturers in India have been at the forefront of adopting and advancing this technology to meet the growing demands of the Indian water industry.

Water Meter test bench with Gravimetric

A Gravimetric Water Meter Test Bench is a specialized and advanced piece of equipment designed to ensure the utmost precision in water measurement. It plays a vital role in the calibration process for water meters, which are crucial devices used in various settings, including residential, commercial, industrial, and municipal applications.

The primary objective of a gravimetric water meter test bench is to verify and adjust the accuracy of water meters. It accomplishes this by precisely measuring the flow of water, comparing it to the measurements of the water meter under examination, and making necessary adjustments to ensure the meter's accuracy. These test benches are equipped with highly sensitive instruments, advanced technology, and carefully controlled conditions to provide the most accurate and reliable results.

By using gravimetric water meter test benches, utilities and water management authorities can guarantee that water meters provide precise measurements. This, in turn, ensures fair billing for consumers and promotes the efficient use of water resources.

Ultrasonic Water Meter Test System

The Ultrasonic Water Meter Test System represents a remarkable advancement in the field of water meter calibration, specifically focusing on ultrasonic water meters. These systems are designed to enhance the accuracy and efficiency of water meter measurements, and they have gained prominence, particularly in India, due to their exceptional performance.

Ultrasonic water meters utilize ultrasonic waves to precisely measure the flow of water within pipes. What sets them apart is their ability to measure even low flow rates with unparalleled accuracy, making them a preferred choice in the industry. Their durability, high accuracy, and minimal maintenance requirements further contribute to their widespread adoption.

In India, manufacturers have been at the forefront of advancing this technology to meet the growing demands of the water industry. The result is a technologically advanced water meter that offers bidirectional measurement capabilities, meaning it can measure water flow in both directions. This is invaluable for applications such as leak detection.

The integration of ultrasonic water meters into the water meter test system landscape has brought about significant benefits, including improved accuracy, longevity, and remote reading capabilities. As the industry continues to evolve, these advancements play a pivotal role in achieving more precise water measurements, responsible resource management, and efficient billing practices. The Ultrasonic Water Meter Test System is at the forefront of these positive changes, ushering in a future of more accurate and efficient water measurement and management.

Level Calibration System

The Level Calibration System is an essential component in various measurement processes, aimed at enhancing the precision and accuracy of measurements. It primarily focuses on ensuring that instruments and devices accurately determine and report levels of substances such as liquids or solids. This system plays a critical role in multiple industries, including manufacturing, construction, environmental monitoring, and more.

The fundamental principle behind a level calibration system is to verify the accuracy of level measurement instruments and make necessary adjustments when deviations are detected. This is crucial in applications where even slight variations in measurement can lead to significant consequences, such as material wastage, product defects, or safety risks.

The calibration process within this system involves comparing the measurements of a level instrument against a known reference, such as a standardized level. If disparities are identified, adjustments are made to align the instrument with the reference, ensuring precise and reliable measurements in the future.

Level calibration systems have far-reaching benefits, including increased product quality, reduced waste, and improved safety in industrial processes. Additionally, in environmental monitoring, these systems contribute to more accurate data collection, which is vital for assessing and mitigating potential environmental hazards.

Bell Prover Calibration Procedure

The Bell Prover Calibration Procedure is a fundamental and indispensable process in maintaining the accuracy and reliability of water measurement systems. It is a key step in the calibration of flow meters, including gas meters and water meters, and is essential for industries such as utilities, manufacturing, and energy, where precise measurements are paramount.

A bell prover is a specialized calibration device designed to compare the accuracy of a flow meter with a known reference. It operates on a straightforward principle: a bell-shaped chamber is filled with a precisely measured volume of fluid, often air or water, over a defined period. The flow meter under calibration is then tested by comparing its measurements to the bell prover's known volume. Any deviations from the reference are recorded and used to make necessary adjustments to the flow meter.

This procedure plays a pivotal role in ensuring that flow meters, whether for gas or liquid, provide accurate and reliable measurements. The accuracy of flow meters is crucial for a wide range of applications, from billing in utilities to quality control in manufacturing processes and environmental monitoring. Inaccurate measurements can lead to financial discrepancies, safety hazards, or suboptimal product quality.

The bell prover calibration procedure involves several key steps:

- Initialization: The bell prover is filled with a precisely known volume of fluid, and its measurements are established as the reference.

- Flow Meter Testing: The flow meter under calibration is connected to the bell prover, and measurements are taken simultaneously.

- Data Analysis: The data collected from the flow meter is compared to the bell prover's measurements.

- Adjustments: If deviations are identified, adjustments are made to the flow meter to align it with the bell prover's reference.

- Verification: The calibration procedure is repeated to confirm that the flow meter now provides accurate measurements.

The bell prover calibration procedure is a meticulous process that requires a controlled environment, precise instrumentation, and skilled technicians to carry out. While it may seem elaborate, it is essential for ensuring the reliability and accuracy of flow meters. The accuracy of these instruments directly impacts industries' operational efficiency, billing accuracy, and the safety of various processes.

The Advantages of Ultrasonic Water Meters

Ultrasonic water meters offer a host of advantages:

- High Accuracy: Ultrasonic meters are known for their exceptional accuracy in measuring water flow. They can detect even the smallest variations in flow rates, ensuring precise measurements.

- No Moving Parts: Unlike traditional mechanical meters, ultrasonic meters do not have moving parts, making them more durable and less prone to wear and tear.

- Low Maintenance: These meters require minimal maintenance, reducing operational costs.

- Bidirectional Measurement: Ultrasonic meters can measure water flow in both directions, which is crucial for applications like leak detection.

- Non-Invasive: Ultrasonic meters do not require cutting into pipes for installation, which simplifies the process and minimizes service disruptions.

- Remote Reading: Many ultrasonic water meters are equipped with remote reading capabilities, enabling real-time monitoring and data collection.

- Longevity: These meters have a longer operational life, providing value for investment over an extended period.

No comments yet