4×8 plasma cutter machine is a type of equipment used for metal cutting, typically with a plasma arc. The dimensions “4’x8′” refer to the size of the cutting table or bed, which measures 4 feet in width and 8 feet in length. This means the machine can accommodate metal sheets or plates up to that size for cutting.

Plasma cutting is a process that utilizes a high-velocity jet of ionized gas, known as plasma, to melt and sever metal. The plasma arc is created by passing a gas, such as compressed air or nitrogen, through a small nozzle at high speeds and then introducing an electrical arc that ionizes the gas. The resulting plasma arc can reach temperatures of up to 30,000 degrees Fahrenheit (16,650 degrees Celsius) and can effectively cut through various metals, including steel, stainless steel, aluminum, and copper.

A 4’x8′ plasma cutter machine is commonly used in industrial settings, fabrication shops, and metalworking industries where large-scale metal cutting is required. It offers the advantage of high cutting speeds, precision, and versatility in terms of the types and thicknesses of metals it can cut. The machine may include additional features such as automated CNC (Computer Numerical Control) systems for precise and repeatable cutting patterns.

There are many kinds of power sources for the customer to choose according to the metal thickness. Such as 65A,80A,100A,125A ,160A and 200A. And the working size of the plasma cutting machine is also customized.

Plasma Cutter Machine Advantage & Features

- The Plasma Cutting Machine can cut all metal sheets. The cutting area is very wide.

- The cutting speed of the metal cutting machine is very fast and the efficiency is high. The cutting speed can reach more than 10m/min.

- The cutting precision is higher than the flame cutting machine. The underwater cutting has no deformation, and the fine plasma cutting has higher precision.

- The Plasma Cutting Machines use a professional plasma CNC system. It is all offline work and humanized operation.

- The CNC Plasma uses the advanced USB interface to work offline with fast data transmission and does not occupy computer resources.

- This Metal Cutting Machine can be compatible with a variety of software.

- The machine is with the function of continued carving when power outages and breakpoints. And the function of processing time prediction and automatic tool setting.

- Affordable factory direct price and one-year warranty.

Plasma cutting is a fast and precise method of cutting metals, and is often preferred over other methods such as oxy-fuel cutting or laser cutting. The plasma cutter machine is controlled by computer software, which allows for precise and repeatable cuts, even in complex shapes and designs.

When operating a plasma cutter machine, it’s important to follow proper safety procedures, including wearing protective gear such as eye protection and gloves. The machine also requires regular maintenance, including cleaning the torch and replacing consumable parts such as the nozzle and electrode.

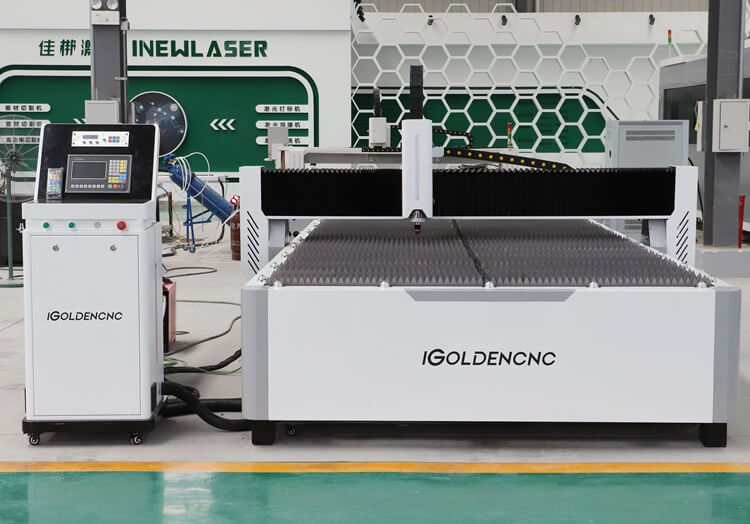

Cheapest 4×8 Plasma Table

This is a 4×8 CNC plasma table cutter,it is very popular in the metal process industry.The 4×8 plasma table cutter has many advanced CNC plasma parts.Such as the high precision plasma cutting head, which has high precision cutting performance and cutting speed. And The aluminum profile gantry beam of this machine is a light duty and fast speed.A 4×8 CNC plasma cutting table is a versatile tool for small to medium-sized businesses and workshops involved in metal fabrication and metalworking. Its ability to cut metal sheets with precision, speed, and efficiency makes it an essential asset for those requiring high-quality and cost-effective metal cutting solutions.

so if you like this 4×8 plasma table for sale, we will provide the most affordable price and the most comprehensive service, please leave your contact information.

iGOLDEN CNC plasma cutting tables are configured with a motion controller that sets the bar for acceleration and deceleration rates, a plasma cutter that increases cut speeds and outlasts competing consumable life cycles by nearly 3x, and a linear motion system that hits gantry and torch travel speeds of up to 500 ipm. All of these features accelerate cost savings for our customers. The faster cut speeds and higher acceleration and deceleration rates reduce job cycle times and increase the amount of metal parts your shop is able to sell.

Key Features of Cnc Plasma Cutting Table:

- Cutting Area: The 4×8 5×10 table provides a spacious cutting area, allowing for the processing of large metal sheets. This is particularly useful for industries that require large-scale metal cutting, such as metal fabrication, manufacturing, and construction.

- Plasma Cutting: Plasma cutting is a thermal cutting process that uses a high-velocity jet of ionized gas (plasma) to melt and remove metal from the workpiece. It is known for its speed and versatility in cutting various thicknesses of metal.

- CNC Control: The machine is controlled by a computer with CNC software. Operators can input cutting designs, and the CNC system precisely controls the movement of the plasma torch to follow those designs, resulting in accurate and repeatable cuts.

- Precision: CNC plasma cutting table offer high precision and accuracy in cutting metal materials, making them suitable for applications that require tight tolerances and intricate designs. Material Compatibility: These machines can cut a variety of metal materials, including mild steel, stainless steel, aluminum, and other alloys. They are versatile and adaptable to different types and thicknesses of metal.

- Speed and Efficiency: Plasma cutting is a fast and efficient process. The high cutting speeds and minimal heat-affected zones reduce production time and labor costs. Customization: Operators can create custom cutting designs, making it possible to produce unique components and parts. This is useful for applications in which specialized or one-of-a-kind pieces are required.

- Minimal Material Waste: Plasma cutting produces minimal waste, which is cost-effective and environmentally friendly.

- Reduced Setup Time: CNC plasma cutting table are designed for quick and easy setup, which is advantageous when switching between different cutting tasks or designs.

CNC Plasma Cutter

The term CNC stands for Computer Numerical Control. That is a CNC cutter will cut through metal using ionized gas with computerized command. A CNC plasma cutter is a type of computer numerical controlled automatic cutting system that uses ionized gas torch to cut metals into different profiles and shapes with CNC controller, including mild steel, stainless steel, carbon steel, galvanized steel, hot rolled steel, cold rolled steel, iron, brass, copper, alloy, aluminum, bronze, and titanium.

A CNC cutter kit is composed of machine frame, controller, power supply, gas torch, blade or sawtooth table, driver, motor, control system, software, guide rail, ball screw, optional parts and consumable parts. Some of the synonyms of a plasma cutter are cutting torch, arc cutter, cutting machine, arc welding cutter, cutting system, plasma table, metal cutter, cutting tool, arc welding machine, or plasma cutting device.

No comments yet