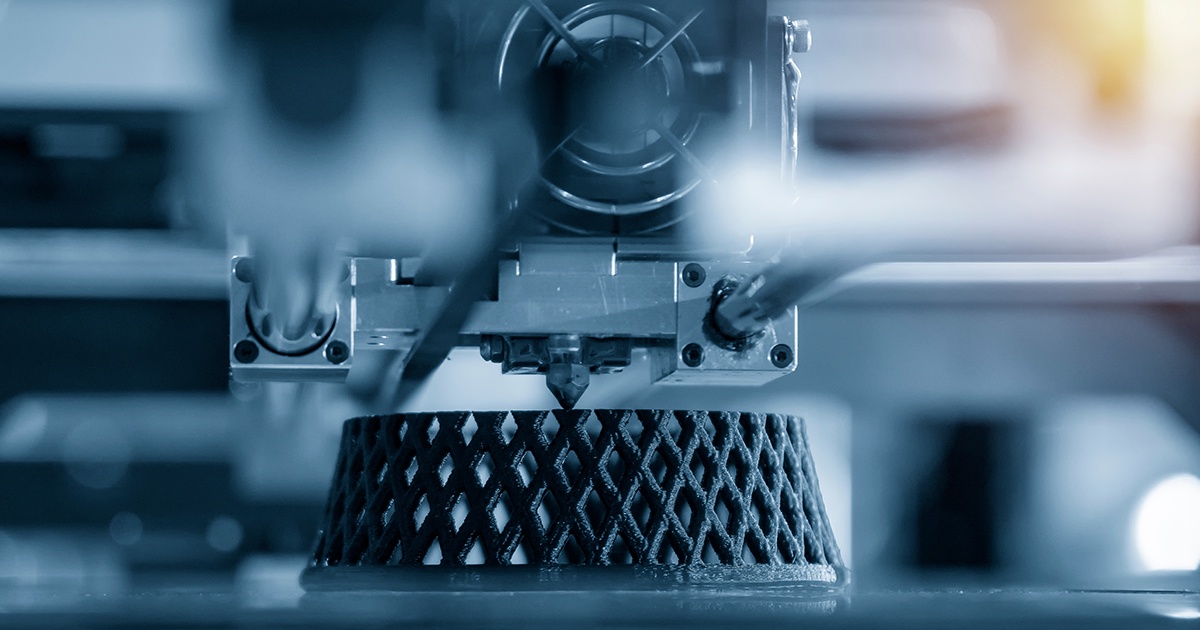

Additive manufacturing (AM) is the process of building parts layer by layer from a digital model. It can be used to produce a variety of materials including metals, ceramics, and polymers.

Unlike traditional manufacturing methods, AM allows for design freedom and a greater opportunity to create customized products. The digital process can also be used to reduce material wastage, enabling rapid prototyping with minimal cost.

Design Freedom

Compared to traditional manufacturing processes, AM materials provide designers with significant design freedom. This enables them to create parts that perform better or cost less than conventional alternatives, which can be especially useful for aerospace and automotive applications.

However, AM also presents some unique challenges. Firstly, AM processes often produce complex shapes and materials distribution that are not possible with traditional manufacturing methods.

In order to take advantage of this potential, designers need to be able to overcome these constraints and exploit the many benefits AM materials can offer. This is where Design for AM (DfAM) comes into play.

Lightweight

Additive manufacturing (AM) materials have the potential to reduce the weight of vehicles. However, they also offer a range of other performance and commercial benefits.

One of the most significant benefits of AM is its ability to minimize material consumption, build time and therefore manufacturing costs. This is a key focus for many manufacturers seeking to reduce production costs while still maintaining component quality.

For example, a lightweight metal AM technique can be used to aluminum additive manufacturing large rear wing flap extensions in composite structures, or hollow composite brake-cooling ducts. The process can also be used to produce custom honeycomb structures that are difficult to fabricate through traditional processes.

Durability

Additive manufacturing (AM) processes allow for the creation of virtually any shape and size, including complex geometries that are difficult or impossible to make through traditional subtractive techniques. This freedom allows designers to create parts that perform better or cost less than their conventional counterparts.

Durability is another benefit that AM materials offer. This means that parts can be manufactured more robustly, making them last longer in the field and saving on support calls and rework costs.

AM materials can be made from a wide range of different polymers, ceramics, and metals. This includes metals such as gold, silver, stainless steel and titanium. Alternatively, they can be created using thermoplastic polymers like acrylonitrile butadiene styrene (ABS), polylactic acid (PLA) and polycarbonate (PC). This means that AM can be used for a wide variety of products.

On-Demand

Unlike traditional manufacturing methods that require dedicated equipment and tooling, AM enables the on-demand production of spare parts from digital files. This enables companies to minimize spare-parts inventories and streamline maintenance operations.

Moreover, AM materials are easy to disassemble and recycle in the event of failures. This significantly reduces waste and costs throughout the product lifecycle.

The on-demand nature of AM also allows for the production of parts for a variety of unique needs and applications. This allows for a more bespoke, high-value, and personalized experience.

This level of customization has been demonstrated in medical devices, such as orthopedic implants. It has enabled surgeons to customize the shape, dimensions, and function of a bone implant, allowing them to match the morphology of the patient. It has also been used in pharmaceuticals, creating pills with customized drug doses and release characteristics.

Speed

Unlike CNC milling, which requires a long, subtractive process, aluminum materials can be used to rapidly prototype new parts. It's a great way to test design changes, and it can reduce costs, particularly when printing smaller quantities.

For example, aerospace companies use AM to create complex, high-strength parts that can withstand harsh environmental conditions. They're also able to print lattice structures that can make their parts lighter and more aerodynamic.

AM can also be used to simplify assembly processes, reduce inventory, or improve product reliability. A fuel injector head for the latest Ariane 6 rocket, for example, was additively manufactured as a single piece.

No comments yet