Introduction

When it comes to industrial heating applications, two popular options stand out: cartridge heaters and duct heaters. Both of these heating solutions offer unique advantages and are designed to cater to specific needs in various industries. In this comprehensive comparison, we will explore the features, benefits, and ideal applications of cartridge and duct heaters, helping you make an informed decision based on your specific heating requirements.

1. Understanding Cartridge Heaters

Cartridge heaters are compact, cylindrical heating elements used for localized heating in machines, tools, and various industrial processes. They consist of a resistance coil embedded in a metal sheath, providing direct heat transfer to the target material. These heaters are known for their versatility, fast heating speeds, and simplicity of installation.

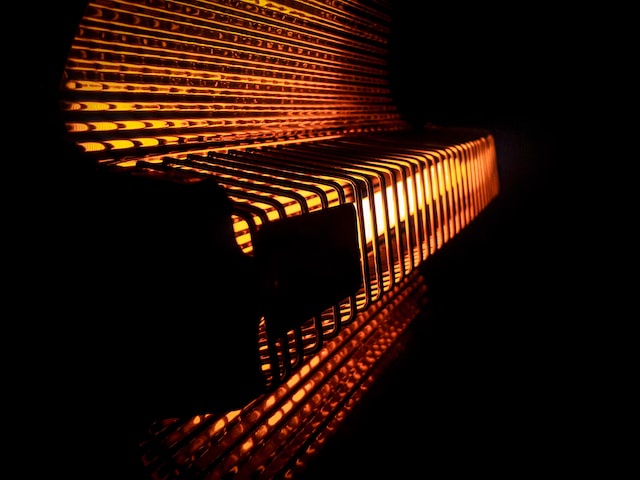

2. Understanding Duct Heaters

Duct heaters, on the other hand, are designed to heat moving air or gases within a duct system. They are larger in size compared to cartridge heaters and are specially constructed to withstand airflow and environmental conditions within ducts. Duct heaters are commonly used in HVAC systems, industrial air heating, and processes where forced air heating is required.

3. Heating Efficiency

3.1 Cartridge Heaters

Cartridge Heater are highly efficient in localized heating applications. Since they directly contact the material, there is minimal heat loss during the heating process. They can quickly reach high temperatures, making them suitable for tasks that demand rapid heat-up times and precise temperature control.

3.2 Duct Heaters

Duct heaters are designed for heating large volumes of air or gases in duct systems. Their efficiency lies in evenly distributing heat throughout the airflow. However, some heat loss may occur during the transfer process due to the nature of forced air heating.

4. Installation and Maintenance

4.1 Cartridge Heaters

Cartridge heaters are relatively easy to install, especially in small spaces where direct heating is required. They are available in a variety of diameters and lengths for various functions. Maintenance typically involves inspecting the connection and ensuring the heater remains securely seated in its mounting.

4.2 Duct Heaters

Installing duct heaters can be more complex due to their larger size and integration into duct systems. Proper positioning within the duct is crucial for even heating. Regular maintenance involves cleaning air filters and checking electrical connections to ensure optimal performance.

5. Applications

5.1 Cartridge Heaters

Plastic molding and extrusion processes

Packaging machinery, such as heat sealing

Hot runner systems in injection molding

Lab equipment and analytical instruments

5.2 Duct Heaters

HVAC systems for commercial and industrial buildings

Industrial ovens and dryers

Air preheating in industrial processes

Air heating in spray booths

6. Temperature Range

6.1 Cartridge Heaters

Cartridge heaters can achieve higher temperatures, typically ranging from 200°C to 1200°C (392°F to 2192°F), depending on the application and sheath material.

6.2 Duct Heaters

Duct Heater generally have a lower temperature range, typically from 0°C to 650°C (32°F to 1202°F). This range is suitable for most forced air heating applications.

7. Customization Options

7.1 Cartridge Heaters

Cartridge heaters offer a wide range of customization options, including different sheath materials, wattage, voltage, and termination styles to suit specific industrial processes.

7.2 Duct Heaters

Duct heaters can also be customized with various wattages, voltage, control options, and airflow designs to meet the specific requirements of different duct systems.

Conclusion

In conclusion, both cartridge heaters and duct heaters serve distinct heating needs in various industrial applications. Cartridge heaters excel in localized heating tasks with their quick response times and precise temperature control. On the other hand, duct heaters are ideal for heating large volumes of air or gases in duct systems. The two options can be chosen depending on the application's needs, heating efficiency, and temperature range. By understanding their features and capabilities, you can select the most suitable heating option to optimize your industrial processes and achieve efficient and reliable heating performance.

No comments yet