Automotive casting is a fundamental manufacturing process that plays a crucial role in the production of automobile components. It involves pouring molten metal into a mold to create intricate and robust parts, ranging from engine blocks to suspension components. In this guide, we will explore the world of automotive casting, covering the types of casting methods, materials used, the casting process, and how innovation is shaping the future of this industry.

Types of Automotive Casting:

-

Sand Casting:

- Sand casting is one of the oldest and most widely used casting methods in the automotive industry.

- It's cost-effective and suitable for creating large, complex components like engine blocks.

- The mold is made of compacted sand, providing flexibility and versatility.

-

Die Casting:

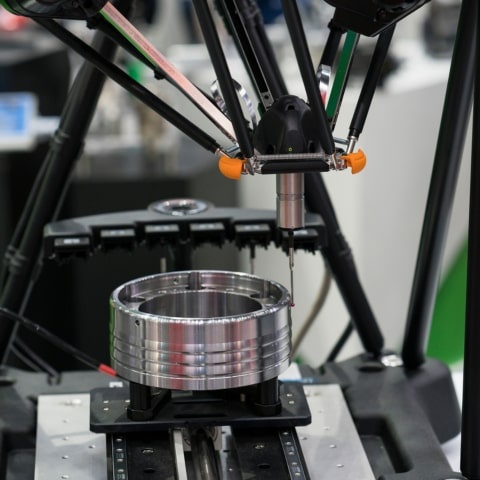

- Die casting is a high-pressure process ideal for producing intricate, high-precision parts like transmission cases and wheel rims.

- It uses metal molds and a fast injection of molten metal, ensuring precise dimensions and surface finish.

-

Investment Casting:

- Also known as lost-wax casting, this method is used for producing detailed and small components, such as turbocharger impellers.

- It yields excellent surface finish and dimensional accuracy but is relatively more expensive.

Materials for Automotive Casting:

-

Aluminum:

- Widely used for lightweight components like cylinder heads and intake manifolds.

- Aluminum is preferred for its excellent thermal conductivity and corrosion resistance.

-

Iron:

- Cast iron is chosen for its durability, making it suitable for engine blocks and brake components.

- It has excellent wear resistance and damping properties.

-

Steel:

- Steel is used for high-stress components such as crankshafts and camshafts.

- It offers a balance between strength and formability.

The Casting Process:

-

Pattern Making:

- The first step involves creating a pattern or replica of the desired component. This pattern is used to form the mold.

-

Mold Preparation:

- Depending on the casting method, the mold is made from sand, metal, or ceramic materials.

-

Melting and Pouring:

- The chosen metal is melted at high temperatures, and then, it is poured into the mold cavity.

-

Solidification:

- The molten metal cools and solidifies within the mold, taking the shape of the desired component.

-

Ejection and Finishing:

- Once the metal has cooled and solidified, the mold is removed, and the cast component is trimmed and finished to meet the required specifications.

Innovation in Automotive Casting:

-

Computer-Aided Design (CAD) and Simulation:

- CAD software allows for the precise design of casting patterns and molds.

- Simulation tools help optimize the casting process, reducing defects and material waste.

-

3D Printing for Prototyping:

- 3D printing is increasingly used to create rapid prototypes of casting patterns, reducing lead times and costs.

-

Metal Additive Manufacturing:

- Additive manufacturing techniques are being explored to directly produce complex metal parts, eliminating the need for molds.

-

Sustainable Casting:

- Eco-friendly initiatives are promoting the use of recyclable and green materials, as well as reducing energy consumption in the casting process.

Conclusion:

The automotive casting is a vital aspect of automobile manufacturing, producing essential components with precision and efficiency. By choosing the right casting method and materials, automotive manufacturers can ensure the durability, performance, and safety of their vehicles. Moreover, ongoing innovations in casting technology promise to enhance the industry's sustainability and flexibility, driving the automotive industry toward a more dynamic and eco-conscious future.

No comments yet