When it comes to fluid transfer, choosing the right pump for your specific needs is crucial. The two main types of pumps are centrifugal and positive displacement. In this guide, we'll focus on positive displacement pumps, including Positive Displacement Chemical Pumps and industrial peristaltic pumps, and how to choose the right one for your fluid transfer needs.

What are Positive Displacement Pumps?

Positive displacement pumps work by trapping a fixed amount of fluid in a cavity and then forcing it through a discharge port. The two main types of positive displacement pumps are rotary and reciprocating.

Rotary Positive Displacement Pumps

Rotary positive displacement pumps are the most common type of positive displacement pump. They work by rotating a mechanism to displace fluid. Some examples of rotary positive displacement pumps include gear pumps, lobe pumps, and screw pumps.

Reciprocating Positive Displacement Pumps

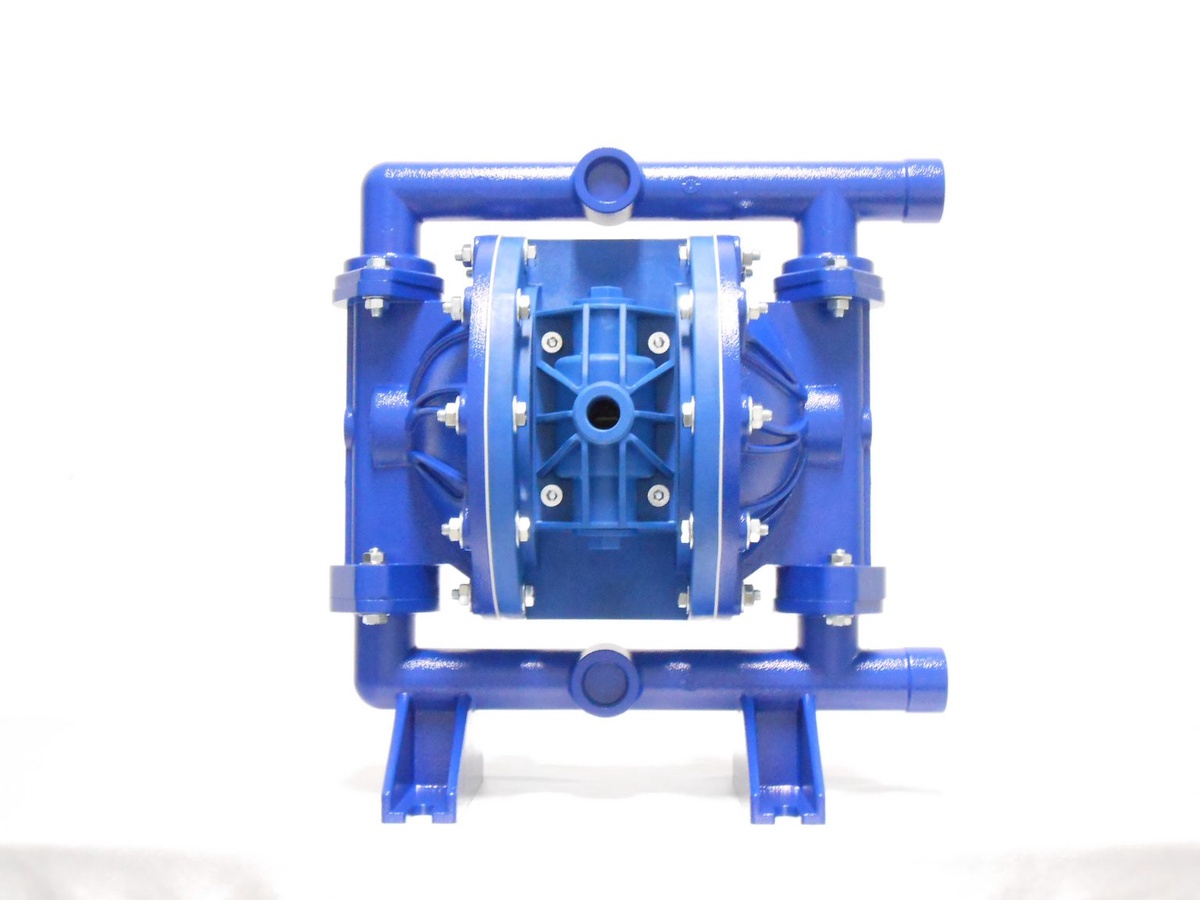

Reciprocating positive displacement pumps work by moving a plunger or piston back and forth to displace fluid. Some examples of reciprocating positive displacement pumps include diaphragm pumps and piston pumps.

How to Choose the Right Positive Displacement Pump

When choosing a positive displacement pump, there are several factors to consider:

- Viscosity: The viscosity of the fluid being pumped is crucial. Positive displacement pumps are designed to handle high viscosity fluids, making them ideal for thick, heavy liquids.

- Flow Rate: The flow rate, or the amount of fluid that needs to be pumped in a given amount of time, is another crucial factor to consider. Positive displacement pumps are ideal for low to medium flow rates.

- Pressure: The pressure at which the fluid needs to be pumped is another important consideration. Positive displacement pumps can handle high-pressure applications.

- Compatibility: Ensure the pump material is compatible with the fluid being pumped. Positive displacement pumps can handle a wide range of fluids, including corrosive and abrasive liquids.

- Maintenance: Positive displacement pumps require regular maintenance, including lubrication, seal replacement, and cleaning. Consider the maintenance requirements before making a purchase.

Positive Displacement Chemical Pumps

Positive Displacement Pumps are designed specifically for handling corrosive and abrasive chemicals. These pumps are made of materials that can withstand exposure to harsh chemicals, making them ideal for use in the chemical industry.

Industrial Peristaltic Pumps

Industrial peristaltic pumps are another type of positive displacement pump. They work by squeezing a flexible tube to displace the fluid. These pumps are extremely ideal for applications where gentle pumping is required, such as in the food and pharmaceutical industries.

In conclusion, choosing the right pump for your fluid transfer needs is crucial. Positive displacement pumps, including Positive Displacement Chemical Pumps and industrial peristaltic pumps, are ideal for handling high viscosity fluids and low to medium flow rates also. When choosing a positive displacement pump, consider factors such as viscosity, flow rate, pressure, compatibility, and maintenance requirements. By taking these factors into account, you can choose the right pump for your specific needs and ensure efficient, reliable fluid transfer. Contact us now if you have any confusion or you want to know more!

No comments yet