DTF (Direct-to-Film) printing has become a popular printing method in recent years, especially for businesses that want to create high-quality and durable prints on fabrics. With its cost-effectiveness, versatility, and high-quality prints, DTF printing is a great option for both small and large businesses. But can you print DTF at home?

The short answer is yes, you can print DTF at home. However, it requires some specialized equipment and materials that may not be readily available to most home users. In this article, we will discuss the equipment and materials needed to print DTF at home and the steps involved in the printing process.

Equipment Needed for DTF Printing at Home

To print DTF at home, you will need the following equipment:

- DTF Printer: A DTF printer is specially designed to print on the DTF film using CMYK ink and white ink. There are several models of DTF printers available in the market, ranging from entry-level to professional-grade.

- DTF Film: The DTF film is a specialized heat transfer paper that is coated with an ink-receptive layer and a special adhesive that allows it to be transferred onto the fabric using heat and pressure.

- Heat Press: A heat press is used to transfer the DTF film onto the fabric. It applies heat and pressure to the film, causing it to adhere to the fabric.

- Computer and Design Software: A computer and design software such as Adobe Photoshop or Illustrator are needed to create the design that will be printed on the DTF film.

- Inks: DTF printers use CMYK ink and white ink to print on the DTF film. The white ink is used as an underbase to ensure that the colors are vibrant and accurate, especially on darker fabrics.

Steps Involved in DTF Printing at Home

The following are the steps involved in DTF printing at home:

You can also start DTF Printing with epson DTF Printers, they are the entry level DTF Printers. They can help you to start your business or fulfill your printing purpose.

- Prepare the Design: The first step is to create or select the design that will be printed on the DTF film. The design can be created using graphic design software such as Adobe Photoshop or Illustrator. Once the design is ready, it is printed onto the DTF film using the DTF printer.

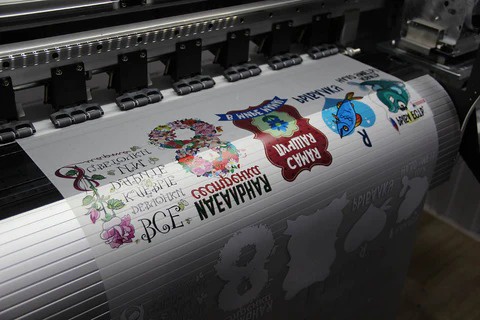

- Print the Film: The DTF printer uses a piezoelectric printhead technology that allows for precise droplet placement and control, resulting in high-quality prints with sharp details and vivid colors. The ink is delivered to the printhead through a system of tubes and channels, and the droplets are fired onto the film at high speeds.

- Transfer the Film onto the Fabric: Once the film is printed, it is ready to be transferred onto the fabric. The film is placed onto the fabric with the printed side facing down, and a heat press is used to apply heat and pressure to the film, causing it to adhere to the fabric.

- Curing the Print: The final step in the DTF printing process is to cure the print. Curing refers to the process of using heat and pressure to set the ink onto the fabric, ensuring that it is resistant to fading, cracking, and peeling.

No comments yet