Electric vehicles (EVs) are the future of the automotive industry. It’s literally revolutionizing the global transportation system, offering an eco-friendly and more sustainable alternative to fuel like petrol or diesel. However, the challenge to EVs is optimizing vehicle efficiency in terms of mileage, speed, and performance. This is where aluminum components play a crucial role in lightweight EVs, aerodynamic designs, and durability.

Aluminum components: Big advantage to EV manufacturers

Aluminum alloys are used in several ways in making diverse automotive components. Well-known components manufacturers such as Rockman Industries have proven expertise in dis casting aluminum alloy wheels, drive chains, suspension components, braking components, body parts, and many other components. For EV manufacturers it’s a huge advantage over traditional materials like steel:

- Lightweight components: Making an EV lightweight is the biggest challenge to the manufacturers. The lighter the vehicles are, the better their fuel efficiency. Every unit reduction in weight directly adds to the driving range for EVs. EV aluminium components boast significantly lower weight than traditional materials like steel.

- Corrosion resistance: This is another big advantage of using aluminium components. Aluminum is naturally corrosion-resistant. Aluminium components are suitable for cars and bikes exposed to adverse weather or road conditions. EV Aluminium components reduce the need for any extra coatings. The overall manufacturing process is simplified and manufacturing expenses are reduced.

- Design flexibility: Aluminum alloys are highly formable. Various complex shapes and designs could be implemented with various categories of aluminium alloys. This characteristic of aluminum helps the manufacturers create intricate shapes and aerodynamic bodies that further make the EVs speedier and fuel efficient.

- Recyclability: Aluminium is one of the most effective recyclable metals on the earth. Aluminium retains almost all its properties even after repetitive recycling. This translates into a more sustainable and cost-effective manufacturing process. When the world is looking for eco-friendly solutions to everything, EV Aluminium components are a step forward toward that effort.

Key EV aluminium components

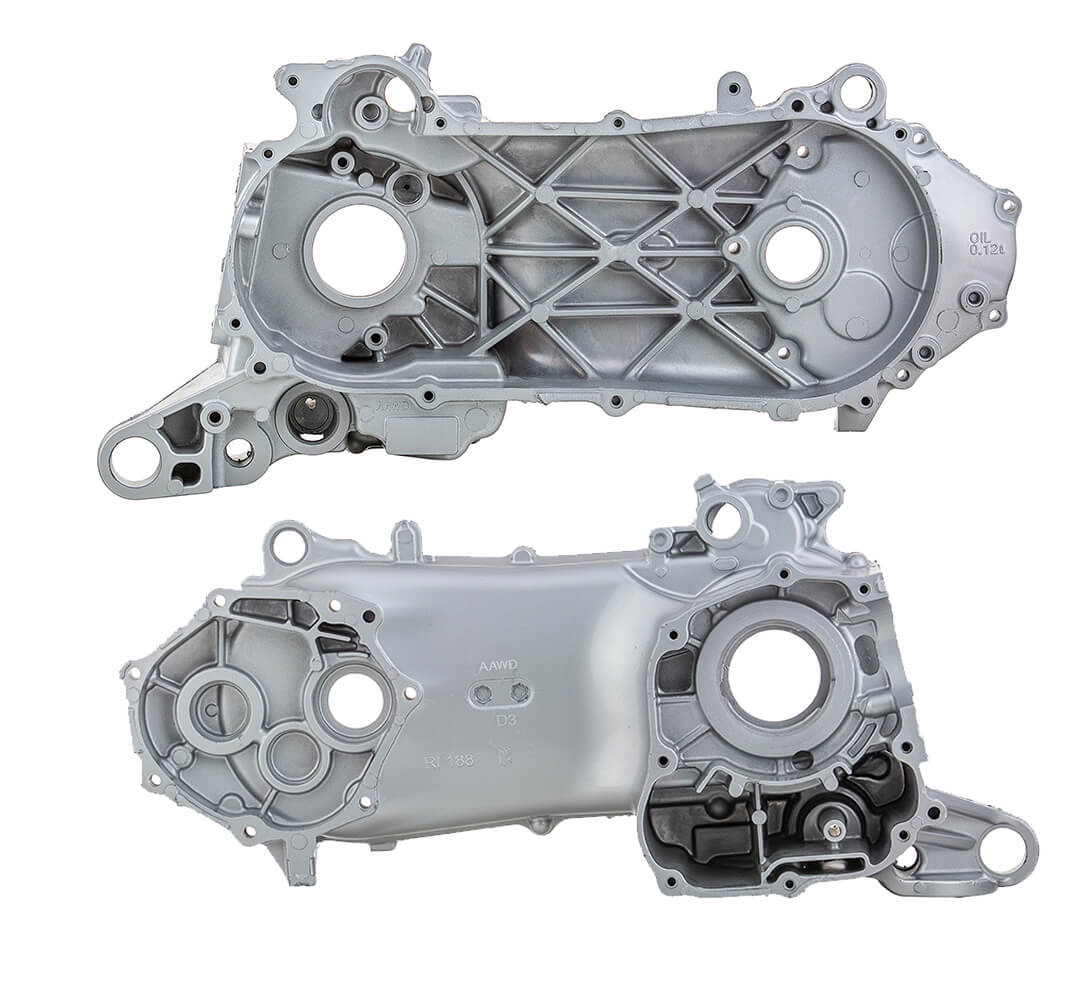

Aluminum die casting is found to be an advantage to EV manufacturers. Meeting their demands for various parts and components, prominent die casting companies such as Rockman Industries provide strong support to EV manufacturers around the globe. Several types of EV components are manufactured with aluminium:

- Battery enclosures: The battery is the heart of an EV. It provides the necessary energy to the engine. Its housing needs to be strong and lightweight. Aluminum has both of these properties. An aluminium housing is at least 30% lighter than a steel housing for a battery. Moreover, aluminium can dissipate heat faster than steel. It protects the battery from external heat and adverse weather.

- Motor housing: EV motor housing needs to be as strong as steel but lighter than steel housing. EV Aluminium components fulfill this requirement also. Aluminium motor housing is designed to be protective and durable. It decreases the weight of the vehicle and contributes to overall efficiency.

- Other components: Several other EV parts such as wheels, suspension components, outer body parts, and heat sinks are also manufactured with aluminium.

Benefits of aluminium components for EVs

The widespread applications of aluminium components for EVs offer various benefits making the vehicles easier to handle and more reliable:

- Enhanced driving range: As the vehicle weight reduces, an EV’s driving range is enhanced significantly.

- Better control: Reduced weight means better control over the vehicle improving the driving expereince of EV owners.

- Improved efficiency: The weight reduction achieved through EV aluminium components leads to reduced energy consumption.

Die casting aluminium components is the game-changer for the EV manufacturing sector. Its core advantages like lightweight, high formability, high corrosion resistance, faster heat dissipation, and high rigidity makes it an ideal material for various EV components.

No comments yet