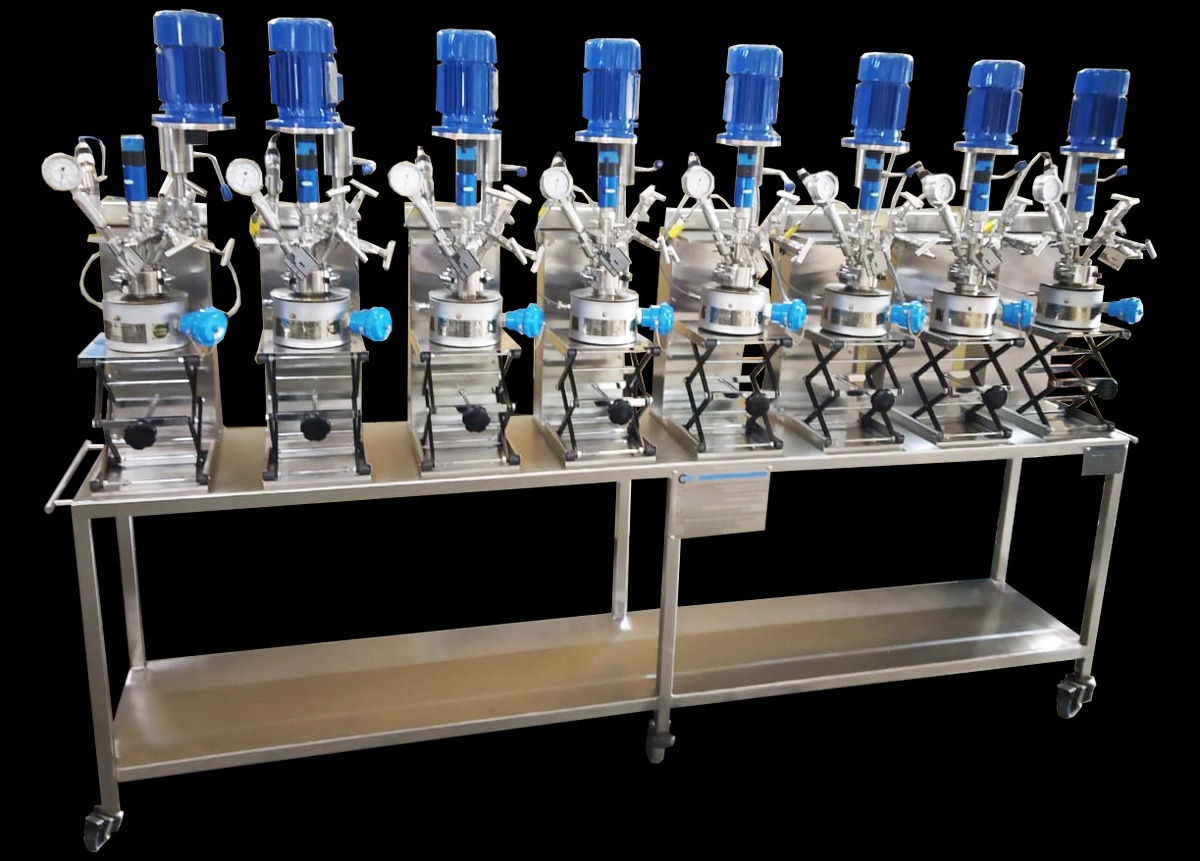

The pharmaceutical sector depends heavily on innovation to discover new medications, improve production methods, and raise product quality. In this endeavor, high pressure reactors have shown to be an invaluable tool, providing a wide range of applications that promote pharmaceutical research and development. These reactors give chemical reactions a controlled setting at high pressure, enabling researchers and engineers to explore new avenues and overcome difficulties. We will examine high pressure reactors' uses in the pharmaceutical sector in this blog article and show how important they are to determining the course of medical advancement.

- Hydrogenation & Catalysis:

For hydrogenation and catalytic processes, high pressure reactors are widely utilised in the pharmaceutical production industry. The process of hydrogenation involves adding hydrogen to unsaturated molecules, which produces useful pharmacological intermediates or finished goods. By providing the ideal pressure, temperature, and selectivity conditions, high pressure reactors make effective hydrogenation processes possible. High pressure circumstances can help catalytic reactions, which use catalysts to speed up chemical transformations, by increasing reaction rates and producing the desired products.

- Synthesis of Active Pharmaceutical Ingredients:

To guarantee excellent purity, yield, and consistent product quality during the synthesis of active pharmaceutical ingredients (APIs), reaction conditions must frequently be precisely controlled. Pharmaceutical chemists can optimise reaction parameters including temperature, pressure, and residence time in high pressure reactors because they provide a controlled and customizable environment. High pressure reactors improve the synthesis of complex APIs, particularly those with difficult stereochemistry, by offering better control over reaction kinetics, resulting in more efficient and economical operations.

- Polymorph & Crystallization Studies:

The bioavailability and stability of pharmaceutical goods can be considerably impacted by polymorphs, which are several crystal forms of the same chemical. In order to better understand polymorphs and crystallisation processes, high pressure reactors are essential. Researchers can investigate several polymorphic forms, find the most stable form, and comprehend the mechanisms underlying their creation by exposing substances to various pressure and temperature circumstances. Using this understanding, pharmaceutical formulations with better bioavailability, solubility, and stability can be created.

- Supercritical Fluid Extraction:

A method called supercritical fluid extraction (SFE) uses supercritical fluids like carbon dioxide to extract desired chemicals from source materials or matrices. High pressure reactors offer the ideal environment for the emergence of supercritical fluid states, improving the extraction effectiveness and selectivity. SFE with high pressure reactors is employed in the pharmaceutical sector for the extraction of bioactive substances from natural sources, the isolation of contaminants, and the purification of pharmaceutical intermediates. This method has a number of benefits, including the ability to extract temperature-sensitive chemicals, lessened solvent usage, and reduced environmental effect.

- Polymerization & Nanoparticle Synthesis:

Pharmaceutical polymers having specified features, such as controlled release, improved stability, or increased bioavailability, are produced using high pressure reactors in polymerization operations. Researchers can regulate the rate of polymerization, the molecular weight, and the structure of the polymer by applying high pressure to monomers. Additionally, the synthesis of nanoparticles for drug delivery systems is made possible by high pressure reactors, allowing for exact control over particle size, shape, and surface properties. These nanoparticles can raise the solubility of drugs, strengthen targeting, and boost therapeutic effectiveness.

Conclusion:

The pharmaceutical business has seen a transformation because to high pressure reactors, which provide a flexible platform for many different chemical reactions and operations. Their uses include polymorph research, supercritical fluid extraction, hydrogenation, catalysis, and polymerization. High pressure reactors give researchers and producers the capability to accurately manage pressure, temperature, and reaction parameters, enabling them to create novel medication formulations, better production methods, and improve overall drug quality. High pressure reactors will stay at the vanguard of the pharmaceutical industry's evolution, enabling innovations in medication research, development, and delivery that will ultimately benefit patients all over the world.

To know more about High Pressure Reactors, please visit - High Pressure Reactors

No comments yet