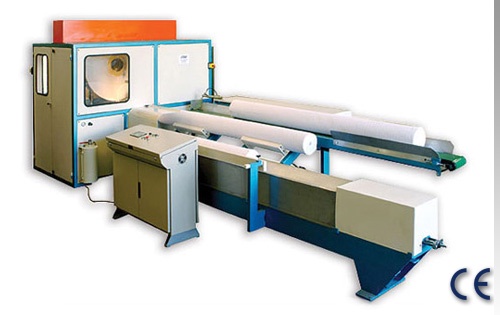

In the manufacturing of hygiene products like toilet paper, paper towels, and facial tissues, precision and efficiency are paramount. A paper log saw is a crucial piece of machinery that offers numerous benefits in this industry. In this blog, we will explore the advantages of using a paper log saw in the production of hygiene products.

- Precision Cutting

- Consistent Length: Paper log saws are designed to cut rolls of paper into precise and uniform lengths, ensuring that every product meets the desired specifications.

- Minimized Waste: Accurate cutting reduces the amount of wasted material, optimizing production efficiency and cost-effectiveness.

- High Production Rates

- Increased Output: Paper log saws are capable of cutting a high number of rolls per minute, significantly boosting production rates.

- Meeting Demand: With the ability to handle high volumes, these machines help meet the ever-increasing demand for hygiene products.

- Versatility

- Customizable Sizes: Paper log saws can be adjusted to cut rolls into various sizes, catering to the diverse needs of customers and markets.

- Multi-Product Use: They can be used for different hygiene products, from toilet paper to kitchen towels, enhancing manufacturing versatility.

- Improved Safety

- Reduced Manual Handling: Automation in cutting reduces the need for manual labor, minimizing the risk of workplace injuries.

- Safety Features: Modern paper log saws are equipped with safety features and protocols to protect operators.

- Enhanced Quality Control

- Visual Inspection: The precision of paper log saws allows for easy visual inspection of the cut products, ensuring that each roll meets quality standards.

- Consistency: Consistent cuts result in uniform product thickness and appearance.

- Efficient Roll Changeover

- Quick Changeovers: Paper log saws are designed for efficient roll changeovers, reducing downtime between production runs.

- Increased Efficiency: Faster changeovers enable manufacturers to respond swiftly to shifts in product demand.

- Cost Savings

- Reduced Labor Costs: Automation and high-speed cutting minimize labor requirements, leading to cost savings in the long run.

- Material Efficiency: Accurate cuts reduce material wastage, further contributing to cost efficiency.

- Scalability

- Adaptable to Growth: As a manufacturing operation expands, paper log saws can be easily scaled up to accommodate increased production demands.

- Market Flexibility: Scalability ensures that manufacturers can pivot and adapt to changing market conditions.

- Consistent Product Appearance

- Professional Finish: The precision cutting of paper log saws results in a clean and professional appearance for each roll, enhancing product appeal to consumers.

- Branding: A consistent appearance is vital for maintaining a brand's reputation and image in the market.

Conclusion

A paper log saw is an indispensable piece of machinery in the hygiene product manufacturing industry. Its ability to provide precision cutting, high production rates, versatility, and cost savings makes it a valuable asset for any manufacturing operation. By investing in this technology, manufacturers can streamline their production processes, meet consumer demands, and ensure the consistent quality of their hygiene products.

No comments yet