In industrial operations, welding is an indispensable process utilized across various sectors, from construction to manufacturing. However, welding poses significant safety hazards amidst its efficiency and utility if not conducted with proper precautions. Ensuring welding facility safety is paramount to protecting workers, equipment, and the surrounding environment. Here are some best practices to uphold safety standards in welding environments, including adherence to proper welding habitat procedures.

Comprehensive Training Programs

One of the foundational pillars of welding safety is providing comprehensive training programs for all personnel involved. These programs should cover the technical aspects of welding and emphasize safety protocols, hazard identification, and emergency procedures. Properly trained personnel are better equipped to recognize risks and respond effectively, mitigating potential accidents.

Personal Protective Equipment

The provision and consistent use of appropriate personal protective equipment (PPE) are non-negotiable in welding habitats. This approach includes welding helmets, gloves, aprons, goggles, and respiratory protection. Employers must ensure that PPE is readily available, adequately maintained, and worn by all workers during welding activities to minimize exposure to hazards such as UV radiation, sparks, and fumes.

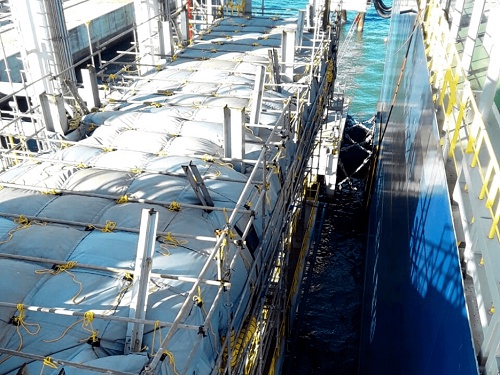

Facility Design

The layout and design of the welding area can impact safety. Make sure there is adequate ventilation to remove fumes and smoke. Use screens or curtains to protect other workers from arc flash. Designate the welding zone clearly and restrict access when welding is in progress. Ensure emergency eyewash stations and fire extinguishers are accessible. Store cylinders securely and design workspaces to avoid tripping hazards.

Adequate Ventilation Systems

Effective ventilation systems are essential to control airborne contaminants generated during welding processes. Local exhaust ventilation (LEV) systems can capture and remove fumes and gases directly at the source, safeguarding workers' health and maintaining air quality in the welding habitat. Regular inspection and maintenance of ventilation equipment are imperative to ensure optimal performance.

Fire Prevention Measures

Welding operations inherently involve high temperatures and sparks, making fire prevention a top priority. Implementing fire safety measures such as proper storage and handling of flammable materials, maintaining clear workspaces, and having firefighting equipment readily available can significantly reduce the risk of fire incidents in welding facilities.

Routine Equipment Inspection and Maintenance

Regular inspection and maintenance of welding equipment are crucial to identify and address potential safety hazards before they escalate. This process includes checking for leaks, damaged cables, and faulty electrical connections and ensuring that equipment is properly grounded. Scheduled maintenance procedures should be documented and adhered to diligently to uphold equipment reliability and safety.

Controlled Access and Signage

Controlling access to welding areas and clearly marking hazardous zones with appropriate signage can prevent unauthorized personnel from entering potentially dangerous environments. Signage should include warnings about specific hazards in the welding habitat procedure, safety instructions, and emergency contact information.

Emergency Preparedness

No welding facility is immune to accidents, making emergency preparedness an indispensable aspect of safety management. Establishing clear emergency procedures, conducting regular drills, and providing first aid training to employees can mitigate the impact of accidents and ensure prompt response in critical situations. Additionally, having readily accessible emergency communication systems and evacuation routes can save lives in the event of an emergency.

Professional Welding Enclosure Services

Hiring professional welding enclosure services is crucial for specialized welding projects or when dealing with hazardous materials. These services provide tailored welding habitats that meet project-specific needs, ensuring optimal containment of hazards and compliance with safety regulations. Professional enclosure services offer expertise, customization, efficiency, and risk mitigation, making them a valuable asset in maintaining a safe working environment.

Conclusion

Safety in welding facilities is a multifaceted endeavor that demands a proactive approach and commitment from all stakeholders. Consider prioritizing safety to protect lives and property and contribute to the overall sustainability of welding operations. Consistent safety training and open communication are key to preventing accidents and upholding high standards.

No comments yet