Introduction:

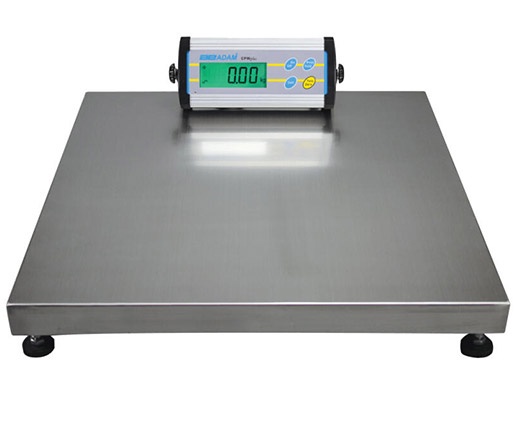

In today's fast-paced business environment, maximizing productivity is crucial for staying competitive. One often overlooked aspect of productivity is the efficient handling of goods and materials within a warehouse or manufacturing facility. This is where industrial floor scale technology comes into play. By accurately weighing and measuring items, these scales can revolutionize your business operations, saving time, reducing errors, and boosting overall productivity. In this article, we will delve into the game-changing benefits of industrial floor scale technology and how it can transform your business.

The Accuracy Advantage

Industrial floor scales offer unparalleled accuracy, enabling precise measurements of items of all sizes and weights. Gone are the days of relying on estimates or manual measurements that are prone to errors. With advanced load cells and calibration techniques, these scales provide reliable and consistent results, leaving no room for guesswork or inaccuracies.

Reliable Load Cells for Uncompromised Precision

The heart of any industrial floor scale is its load cells. These electronic devices detect and measure the weight placed on the scale platform. The accuracy of a scale heavily relies on the quality and performance of its load cells. Advanced load cells, such as strain gauge or hydraulic load cells, are designed to provide precise and reliable weight measurements, even in demanding industrial environments.

Calibration and Verification for Accurate Readings

To maintain accuracy over time, regular calibration and verification of industrial floor scales are essential. Calibration involves adjusting the scale to ensure it provides accurate readings, while verification involves testing and confirming that the scale meets specified accuracy standards. This ensures that your business can rely on the scale's measurements for critical operations such as inventory management and quality control.

"Accuracy is the foundation of productivity. By investing in industrial floor scales, you eliminate the uncertainties and errors associated with manual measurements." - John Adams, Warehouse Manager

Streamlined Workflows with Enhanced Efficiency

Industrial floor scale technology not only enhances accuracy but also streamlines workflows, improving efficiency across various business operations. Let's explore some of the key areas where industrial floor scales can make a significant impact:

Efficient Goods Receiving and Shipment

Receiving and shipping goods are fundamental processes in any business. Industrial floor scales simplify these tasks, enabling quick and accurate weight measurements. By integrating floor scales into your receiving and shipping areas, you can ensure that incoming and outgoing shipments are properly accounted for, reducing the chances of errors, discrepancies, and shipping delays.

Optimized Inventory Management

Inventory accuracy is crucial for preventing stockouts, improving customer satisfaction, and reducing carrying costs. Industrial floor scales play a vital role in inventory management by accurately weighing incoming and outgoing goods. By implementing scale-driven processes, such as weight-based inventory control and automated reordering systems, you can streamline operations, minimize stock discrepancies, and keep inventory levels optimal.

Precise Recipe and Formula Weighing

In industries such as food production and pharmaceuticals, precise recipe and formula weighing are essential for product consistency and compliance. Industrial floor scales with fine increment measurements and advanced features, such as tare weight functionality, enable accurate weighing and proportioning of ingredients. This results in consistent product quality, reduces waste, and ensures regulatory compliance.

- Industrial floor scales streamline workflows, improving efficiency in areas such as goods receiving, shipping, inventory management, and recipe weighing.

- By incorporating scale-driven processes, businesses can minimize errors, reduce stock discrepancies, and maintain optimal inventory levels.

The Cutting-Edge Technologies Enhancing Industrial Floor Scales

Industrial floor scale technology has evolved significantly over the years, introducing innovative features and technologies that further enhance productivity. Let's explore some of the cutting-edge advancements that make these scales indispensable in modern business environments:

Wireless Connectivity and Integration

Wireless connectivity has revolutionized industrial floor scales, allowing seamless integration with other systems and devices. Scales equipped with wireless technologies can communicate with computers, barcode scanners, printers, and inventory management software, eliminating the need for manual data entry. This integration reduces human errors, saves time, and ensures real-time visibility into weighing data across different departments and systems.

Portable and Mobile Solutions

Conventional floor scales are often fixed in one location, limiting their usability and flexibility. However, the latest advancements in industrial floor scale technology have introduced portable and mobile solutions. These scales can be easily moved across different areas of your facility, providing on-the-spot weighing and measurement capabilities where needed. Portable scales are especially beneficial for organizations that require versatility and frequently shift their operations or handle goods in multiple locations.

Advanced Data Management and Analytics

Industrial floor scales with advanced data management capabilities allow businesses to analyze and derive insights from weighing data. With features like data logging and integration with analytics software, scales can track and record measurement data over time. This data can be analyzed to identify trends, optimize processes, and make data-driven decisions for continuous improvement.

"The ability to track and analyze weighing data has been a game-changer for our business. We now have a comprehensive understanding of our manufacturing processes and can make informed decisions to enhance productivity." - Mark Davis, Production Supervisor

Conclusion

Industrial floor scale technology presents an incredible opportunity to boost your business productivity. With their unmatched accuracy, streamlined workflows, and cutting-edge features, these scales can revolutionize the way you handle goods, manage inventory, and maintain quality control. By embracing this game-changing technology, you set your business on the path to enhanced efficiency, reduced errors, and improved overall productivity.

So, why wait? Take the leap and invest in industrial floor-scale technology to unlock the full potential of your business operations.

Also Read- Increase the Efficiency of Your Laboratory with Top-Notch Pipette Calibration Services

No comments yet