The Benefits of CAD Software for Manufacturing

Introduction

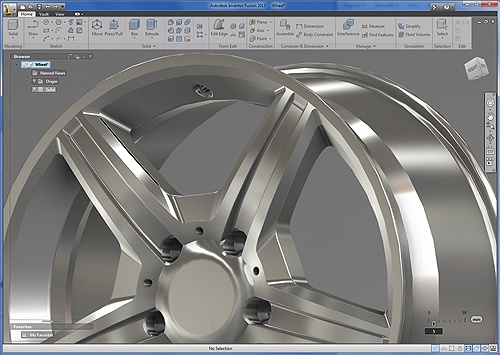

In today's highly competitive manufacturing industry, staying ahead of the curve is imperative. One essential tool that has revolutionized the manufacturing process is Computer-Aided Design (CAD) software. From creating 2D drafts to intricate 3D models, CAD software offers numerous benefits that improve efficiency and productivity in the manufacturing sector. In this article, we will delve into the benefits of free CAD software for manufacturing, highlighting its role in streamlining operations, reducing errors, enhancing collaboration, and increasing overall profitability.

Streamlined Operations

One of the primary benefits of CAD software for manufacturing is its ability to streamline operations. Gone are the days of manually creating blueprints and technical drawings. CAD software allows manufacturers to design complex components and assemblies digitally, eliminating the need for time-consuming manual work. With CAD software, manufacturers can create 2D and 3D models, perform virtual simulations, and even generate material lists and bills of materials with just a few clicks.

Reduced Errors

Another significant advantage of CAD software in manufacturing is its potential to reduce errors. In traditional methods, human errors in measurements and calculations were common, leading to costly mistakes and delays. However, CAD software provides precise and accurate measurements, eliminating the risk of errors caused by human factors. Additionally, CAD software allows manufacturers to detect design flaws and potential issues before production, enabling them to make necessary revisions without incurring substantial costs.

Enhanced Collaboration

Collaboration plays a crucial role in the manufacturing process, and CAD software facilitates seamless collaboration among designers, engineers, and other stakeholders. With the ability to create and share digital designs in real-time, CAD software enables teams to work together efficiently. Furthermore, CAD software allows for easy integration with other software tools, such as computer-aided manufacturing (CAM) software, leading to a seamless transition from design to production.

Increased Profitability

CAD software not only improves efficiency and reduces errors but also contributes to increased profitability in the manufacturing industry. By streamlining operations and reducing costs associated with manual drafting, CAD software helps manufacturers save both time and money. Additionally, CAD software enables manufacturers to explore multiple design iterations quickly, resulting in optimized designs that can enhance product performance, reduce material waste, and ultimately lead to cost savings.

Conclusion

In conclusion, the benefits of CAD software for manufacturing are undeniable. By streamlining operations, reducing errors, enhancing collaboration, and increasing profitability, CAD software has become an essential tool for manufacturers around the world. Embracing CAD software unlocks endless possibilities and opens doors to innovation, allowing manufacturers to stay ahead in a fiercely competitive market. As technology continues to evolve, the role of CAD software will only become more critical in driving success in the manufacturing industry.

No comments yet