Capacitor Discharge (CD) welding machines represent a significant leap in welding technology, offering rapid, high-quality welds with minimal heat input. Taylor-Winfield Technologies, a pioneer in the field of material joining equipment, has been instrumental in advancing CD welding machines, making them a cornerstone in manufacturing industries where precision and efficiency are crucial.

The Power of Capacitor Discharge Welding

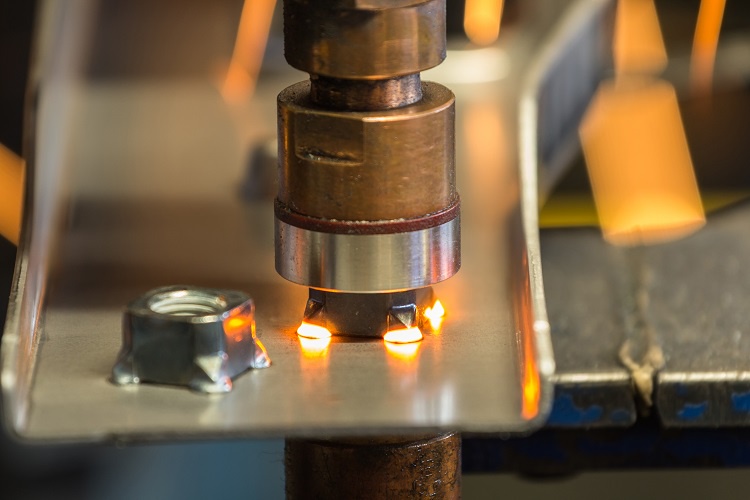

CD welding utilizes the energy stored in capacitors to create a weld in milliseconds. This process is ideal for joining small parts and thin materials where traditional welding methods could cause warping or damage due to excessive heat. Taylor-Winfield’s CD welding machines harness this technology to provide fast, consistent, and high-quality welds.

Taylor-Winfield’s CD Welding Machines: Features and Benefits

- Rapid Welding Cycles: The CD welding machines from Taylor-Winfield are designed for speed, completing welds in a fraction of the time required by other methods.

- Precision Welding: With precise control over the welding parameters, these machines deliver accurate and repeatable welds, ensuring high-quality joints.

- Energy Efficiency: The capacitors in CD welding machines require less energy compared to continuous power sources, leading to cost savings and a reduced carbon footprint.

- Minimal Heat Input: The quick discharge of energy localizes the heat to the weld area, minimizing the heat-affected zone and preserving the integrity of the parts being joined.

- Versatility: Taylor-Winfield’s CD welding machines can join a wide range of materials, including dissimilar metals, expanding their applicability across various industries.

Innovations in CD Welding by Taylor-Winfield

Taylor-Winfield Technologies has introduced several innovations in their CD welding machines, such as the Multi-Capacitor Source (MCS) system. This system allows for a flexible and controlled release of energy, enabling the welding of different materials and thicknesses with precision.

Applications of CD Welding Machines

The versatility of CD welding machines makes them suitable for numerous applications, including:

- Automotive Industry: For welding components like airbag initiators, electrical contacts, and battery tabs.

- Electronics Manufacturing: Ideal for joining delicate electronic components without damaging adjacent areas.

- Medical Device Fabrication: Ensures strong, clean welds for medical devices where hygiene and precision are paramount.

Taylor-Winfield’s Commitment to Quality and Innovation

Taylor-Winfield Technologies is committed to providing not just machines, but complete welding solutions. Their dedication to innovation is evident in their ongoing research and development efforts, aimed at enhancing the capabilities of CD welding machines. The company’s focus on customer support ensures that clients receive comprehensive assistance, from machine selection to after-sales service.

Conclusion

Taylor-Winfield Technologies’ capacitor discharge welding machines are a testament to the company’s legacy of excellence and innovation in the welding industry. By offering machines that are fast, precise, and energy-efficient, Taylor-Winfield continues to set the standard for capacitor discharge welding machine manufacturers. As the demand for advanced welding solutions grows, Taylor-Winfield remains at the forefront, ready to meet the challenges of modern manufacturing with their state-of-the-art capacitor discharge welding machines.

No comments yet