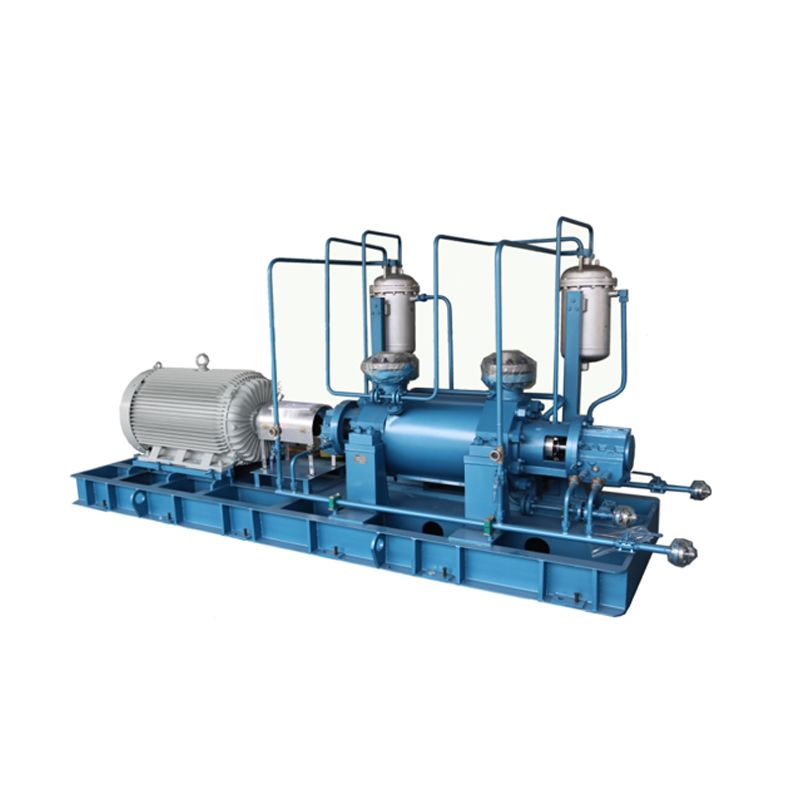

What are Centrifugal Pumps and where are they used?

Centrifugal Pumps are devices that use a rotating impeller move fluids. These are typically used in a lot of different industries such as farming, construction, chemical, and oil and gas. The pump functions by transforming mechanical energy hydraulic power, which moves the fluid from one place to another. Centrifugal Pumps are used when it comes to quantity of applications, including transferring water and other liquids, distributing water to irrigation systems, and going oil and gas through pipelines.

Advantages of Centrifugal Pumps

One regarding the main advantages of Centrifugal pump is the efficiency. They are able to move big levels of fluid at high speeds, helping to make them perfect for applications that want lots of fluid to be moved quickly. Another advantage may be the ease of use. Centrifugal Pumps are relatively simple devices need little maintenance and could be operated by you aren't basic training.

Innovation in Centrifugal Pumps

Over time, there has been innovations which may be many Centrifugal technology Pump. One of the most extremely significant may be the use of adjustable frequency drives (VFDs), which enable the pump to run at various speeds. This may reduce energy usage and improve effectiveness. Other innovations include the use of materials that are resistant to corrosion and wear, which extends the complete life the pump.

Safety Considerations

When using Centrifugal Pumps, safety is a top issue. Operators ought to be trained on how to operate the pump properly and should wear protective gear such as gloves and eye protection. The pump should be properly secured also to prevent it from tipping over or moving during procedure.

How to Use a Centrifugal Pump

Using a Centrifugal Pump is not very hard. The Chemical centrifugal pumps ought to be set up so the inlet is underneath the fluid level and the outlet is above it. After the pump is set up, it might be switched on and the impeller shall start rotating, that will move the fluid through the pump and out of the socket.

Service and Maintenance

Regular service and maintenance are necessary for keeping the pump running well. Including checking the pump for leaks or damage, replacing damaged or worn parts, and lubricating the pump as required. It truly is also important to clean the pump regularly to prevent buildup and make sure it is functioning properly.

Quality and Durability

When choosing a Centrifugal Pump, durability and quality are crucial factors to start thinking about. High-quality pumps are produced from materials that are resistant to wear and corrosion and are available to continue for a long period. It's important to pick out a pump that fits the needs of the sure application to select built one to last.

Applications of Centrifugal Pumps

Centrifugal Process pump are used in many different applications including

1. Agriculture - Pumps are used to go water and fluids through irrigation systems.

2. Construction - Pumps are used to move water, concrete, and other materials.

3. Chemical - Pumps are used to go chemicals and other liquids through pipelines.

4. Oil and gas - Pumps are used to go oil and gasoline through pipelines.

No comments yet