CNC Machining Metal Prototypes - Is It The Best Choice?

During the product development process, many companies use prototypes to test with Aluminum Beads out new products and make sure they’re working properly. Prototypes are also a great way to see if there are any design changes that need to be made.

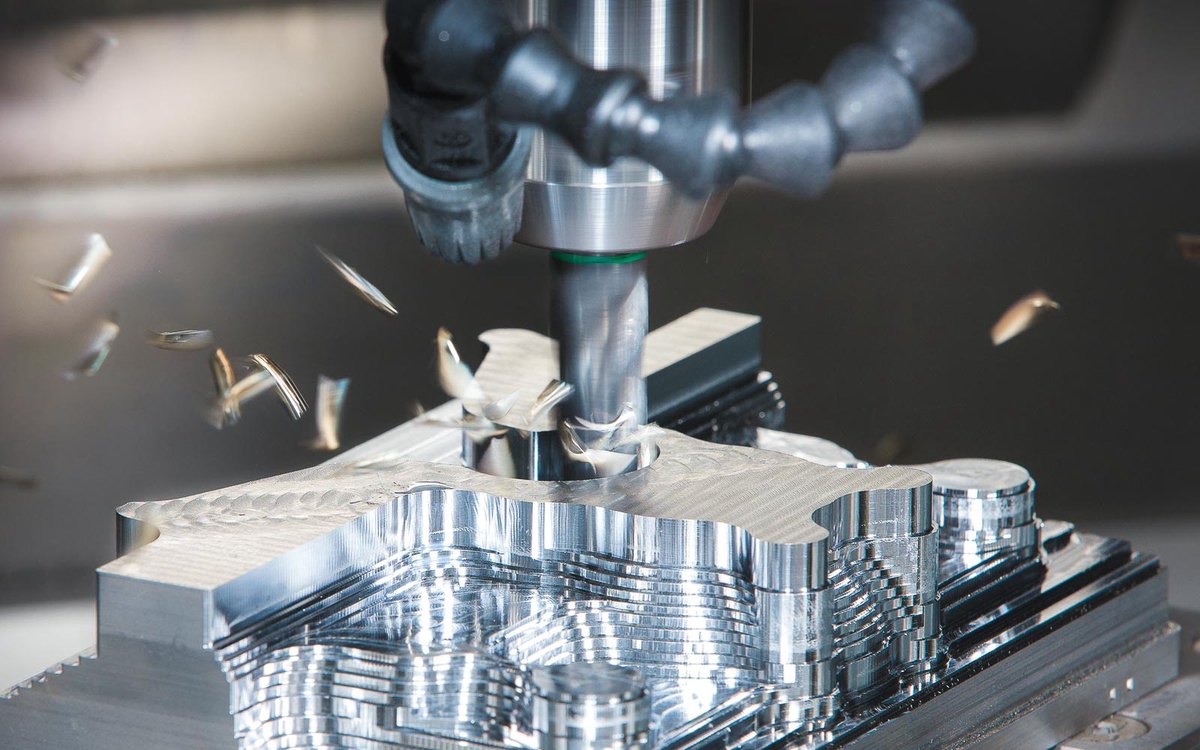

While CNC prototyping is a great option for creating metal prototypes, there are some pros and cons to consider before deciding to use it.

Cost

CNC machining can be an extremely cost-effective prototyping process. Its high-speed and precision capabilities allow you to make a wide range of prototypes that closely mirror the final product.

The first step is to define what types of prototypes you need. This will help you narrow down the options and find a machine that will work best for your business. The type of materials you plan to use will also determine which type of CNC machine is best for your needs.

In addition, you should consider how complex your prototypes are. This will determine whether or not you need a dedicated machine with multiple tool setups and sophisticated software for optimal functionality.

For example, if your product will require many complicated features and intricate geometric shapes, you may want to consider using a dedicated machine for your prototyping needs. This can help reduce the overall costs of your prototypes while increasing their quality.

Another benefit of using a CNC machine for your prototypes is that you can get high-quality parts that are easy to clean and maintain. This makes them perfect for demonstrating new features and engineering changes.

You can create prototypes in a variety of different materials, including plastics, metals, wood and engineered materials. This allows you to test a wide range of material options without having to compromise on functionality or durability.

Moreover, you can also add finishing touches to your CNC-machined prototypes, like polishing or powder coating. These steps will add a shine to your parts and make them look more like the real thing.

If you need metal prototypes that have very tight tolerances, then it is probably worth investing in a dedicated CNC machine. This will give you the ability to produce parts with ultra-tight tolerances that aren’t possible with other prototyping methods. These tight tolerances are crucial for manufacturing high-quality prototypes that are compatible with the final product.

Speed

Creating a functional prototype of a new product allows manufacturers to determine its properties, visual appeal, and durability. It also helps them eliminate defects that might occur in a production run. CNC machining is often used for prototyping because it can create accurate models of parts using a variety of materials.

When working with a reputable CNC machining partner, you can expect your prototype to be machined and ready to test in no time. Unlike 3D printing, which can take weeks to complete, CNC machining is a fast process that can produce hundreds of parts in a short amount of time for Medical Devices Parts.

The first step in preparing for a CNC prototype is to draft CAD designs that fit the desired product. This will ensure that the machining process is able to efficiently use the design and avoid unnecessary costs and time delays.

Another important consideration for the drafting stage is to make sure that the drawings are simple and easy to modify if necessary. Many CAD applications offer different tools for designing complex parts and features, so it is best to choose a program that will suit your needs.

Once the CAD file is finalized, the next step is to create a 3D model with 3D Printer Parts that is compatible with the CNC machine. The 3D model will tell the machine what to do with the material it is machining and how to create the desired surface finishes.

Finally, the prototype is then tested and approved by product experts. If it fulfills all requirements, the prototype is sent to production. However, if it does not, the prototype is redesigned and the second-best ideation is machined instead.

Medical Equipment Prototypes:

The medical industry is constantly evolving and requires new types of equipment to treat different ailments. Whether it’s an orthotic device, implant, safe enclosure, or research equipment, these companies need to see that their products can function properly before they go into production.

Since CNC machining is a reliable process that provides tight tolerances and high accuracy, it is the perfect choice for producing functional prototypes of these medical devices. Other methods, such as injection molding, do not have the same accuracy and may not be able to reproduce the exact features of the original design.

Accuracy

CNC machining is one of the best ways to create precision prototypes. It can also be used in conjunction with other prototyping techniques, including casting and 3D printing.

Using CNC machined parts for prototypes allows manufacturers to make accurate copies of the real thing in a short time. This is useful for medical equipment, for example, where there is a need to test the product before going to production.

To create a prototype, engineers first need to use CAD software. It must be compatible with the type of part they want to produce. This will help them to ensure the CAD file is efficient and can be programmed easily by a CNC machine.

The CAD file is then converted into G code, which tells the machine how to move. The machine can then cut the design in a variety of materials using a variety of tools.

These tools include ball end mills, face mills, and a sanding belt. They can be changed in seconds, enabling a high-quality finish to be achieved without wasting material or time.

Unlike 3D printing, CNC machining can achieve extremely tight tolerances and can be used in a variety of metals. Moreover, it can be used to produce parts with high durability and toughness.

Another benefit of CNC machining is that it can be used to create more complex shapes than other types of prototypes. In fact, some machines can be equipped with up to nine axes. This is a big advantage in the case of difficult-to-machine parts that require tight tolerances and precise machining.

This makes it a great choice for a variety of industries, as it is highly versatile and practical. It is especially useful for manufacturing medical equipment, such as orthotic devices and safe enclosures.

In order to achieve the highest level of accuracy, it is vital that a machined prototype can match the design that was created with the CAD file. Fortunately, CNC machining can be used to create an exact replica of any design.

Durability

CNC machining is a subtractive manufacturing process that takes a workpiece, removes unwanted material with a cutting tool, and shapes the part into the desired shape. The process requires specialized cutting tools and complex setups, which can increase the prototype’s cost and development time for anodized cnc parts.

It also leads to a lot of material waste because the machine cuts through metals, which can become chipped and useless for other purposes. In addition, the process uses a high level of energy and requires labor-intensive operations to complete the job.

In comparison, 3D printing is an additive manufacturing process that builds a prototype layer by layer. However, it produces high levels of material waste, which can add to the prototype’s costs and development time. In addition, it cannot make functional prototypes with complex internal geometry because the parts are made from the outside in.

Despite the limitations of 3D printing, it is still the best option for some applications. For example, the medical industry often uses it to create equipment such as orthotic devices, safe enclosures, and MRI machines.

This application requires equipment to be very accurate, and it is important that the prototype closely mirrors the final product so that there are no issues with its function. For this reason, CNC machining is the best option for making these types of prototypes.

CNC machining can produce prototypes in a variety of materials, from the hardest alloys and metals to materials such as wood and plastics. This makes it an ideal option for testing new designs and materials before committing to a final product.

Prototypes created using this technique tend to have with anodized cnc machining parts a high degree of similarity to the final product, due to their materials and the process itself. This allows engineers to get feedback from their machinists before committing to full-scale production.

In addition, CNC machining can make prototypes in the same material that they will eventually be made from when the product goes into mass production. This means that the machining of a prototype can be more accurate than other prototyping methods.

For these reasons, it is a great choice for medical prototypes. The process is also used to create other forms of medical equipment, including safe enclosures and implants. The machining of these prototypes can be extremely precise, which helps medical companies ensure that the products are functioning properly.

No comments yet