Imagine a world where manufacturing processes are not just efficient but also remarkably precise, where intricate designs are brought to life with utmost accuracy. This is where CNC technology steps in, revolutionizing industries and shaping the future of manufacturing. In this article, we'll delve into the cnc meaning, its significance, how it operates, its types, advantages, applications across sectors, future trends, challenges, and why it matters in today's dynamic landscape.

Introduction

CNC, short for Computer Numerical Control, is a sophisticated technology that empowers machines to carry out precise operations with minimal human intervention. It's the backbone of modern manufacturing, enabling intricate designs and complex shapes to be replicated with impeccable accuracy. The evolution of CNC has not only streamlined production processes but has also elevated standards in terms of quality and efficiency.

What Does CNC Stand For?

CNC stands for Computer Numerical Control. This technology involves the use of computer programs to automate machine tools, such as lathes, mills, and routers, for precise and repetitive tasks. The concept traces back to the 1940s when John T. Parsons pioneered numerical control, laying the groundwork for today's CNC systems.

How Does CNC Work?

At its core, CNC operates based on digital instructions fed into the machine's computer. These instructions, often in the form of G-code, dictate the precise movements and operations the machine will perform. CNC machines are equipped with motors that drive the cutting tools, following the programmed paths with incredible accuracy.

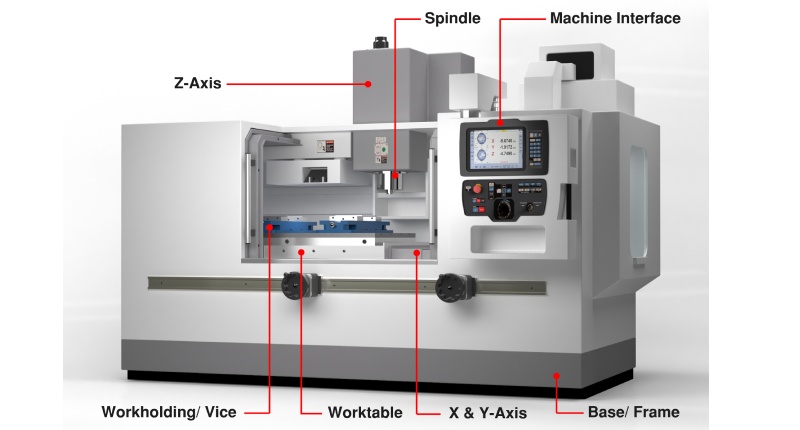

Types of CNC Machines

CNC technology encompasses a wide range of machines tailored for specific tasks. These include CNC routers used for cutting and shaping materials like wood and plastics, CNC mills for metalworking operations, CNC lathes for cylindrical parts, and advanced multi-axis machines for complex geometries.

Advantages of CNC Technology

The adoption of CNC technology brings a plethora of benefits to industries. One of the key advantages is the unparalleled precision and accuracy it offers, leading to consistent quality in production. Moreover, CNC machines enhance productivity by reducing setup times and enabling continuous operation, thus optimizing workflow efficiency.

Applications of CNC Machines

The versatility of CNC machines extends across various sectors. In the automotive industry, CNC machining is crucial for manufacturing precision components like engine parts and chassis components. Aerospace companies rely on CNC technology for crafting intricate aircraft components with tight tolerances. The medical sector benefits from CNC's precision in producing surgical instruments and implants. Even hobbyists and DIY enthusiasts utilize desktop CNC machines for crafting customized projects.

Future Trends in CNC

Looking ahead, the future of CNC is intertwined with advancements in artificial intelligence (AI) and machine learning. These technologies will enhance CNC systems' capabilities, enabling self-optimization and predictive maintenance. Sustainability is also a growing focus, with CNC manufacturers exploring eco-friendly materials and energy-efficient processes.

Challenges in CNC

While CNC technology offers immense advantages, challenges persist. The initial investment required for acquiring CNC machines and training personnel can be substantial. Additionally, there is a demand for skilled operators and programmers who can harness the full potential of CNC systems.

Conclusion

In conclusion, CNC technology has redefined the landscape of manufacturing, offering precision, efficiency, and versatility across industries. As we embrace advancements like AI integration and sustainable practices, CNC's role in shaping the future of production is set to expand further, driving innovation and excellence.

FAQs (Frequently Asked Questions)

- What are the primary components of a CNC system?

- Can CNC machines work with different materials?

- How is G-code essential in CNC programming?

- What is the difference between CNC milling and CNC turning?

- Are there affordable options for small businesses to adopt CNC technology?

No comments yet