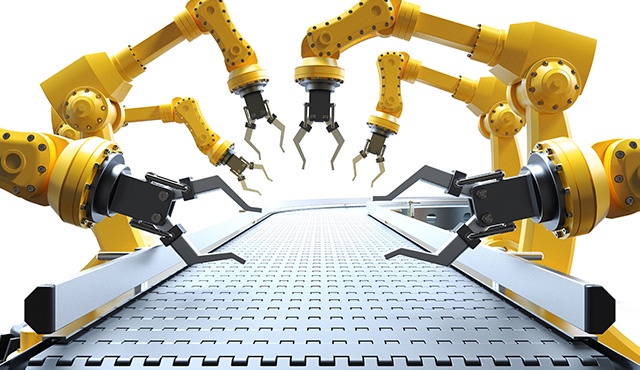

In the realm of industrial evolution, the emergence of Collaborative Robots (or cobots) stands as a pivotal milestone, redefining the landscape of Automation Robotics and particularly revolutionizing the sphere of machine tending.

The Evolutionary Leap

Automation Robotics have long been the cornerstone of manufacturing prowess, optimizing processes, and driving efficiency. However, the advent of Collaborative Robots represents a quantum leap in this arena. These robots, unlike their traditional counterparts, are designed to interact and collaborate seamlessly with human counterparts, ushering in a new era of adaptable automation.

Unveiling Unparalleled Flexibility

Traditional Automation Robotics often operated within predefined parameters, excelling in repetitive tasks but lacking the adaptability required in dynamic settings. Enter Collaborative Robots, engineered with sensors and advanced algorithms, enabling them to learn and adapt swiftly to varying tasks. This ability to work in tandem with human operators without compromising safety has transformed the notion of machine tending.

Redefining Human-Robot Collaboration

The integration of Collaborative Robots in machine tending has birthed the concept of human-robot collaboration (HRC). It's not merely about robots performing tasks; it's about robots and humans complementing each other's strengths. This symbiosis optimizes workflows, enhancing efficiency while ensuring a safe and conducive working environment.

Enhanced Efficiency and Precision

The marriage of Collaborative Robots with Automation Robotics in machine tending endeavors unlocks a realm of possibilities. While traditional automation ensures precision and consistency in tasks, the adaptability of cobots supplements this by handling tasks that demand flexibility and human-like decision-making.

Bridging the Gap in Industry 4.0

The era of Industry 4.0 demands interconnectedness and agility in manufacturing. Collaborative Robots bridge the gap by combining the strength of human intuition with the efficiency of automated systems. Their capability to collaborate, learn, and evolve aligns seamlessly with the demands of a rapidly changing industrial landscape.

The Road Ahead: Innovations and Challenges

As Collaborative Robots continue to evolve, innovations in AI, machine learning, and sensor technology are poised to amplify their capabilities. However, challenges such as regulatory frameworks and ensuring seamless integration into existing workflows remain focal points for industry leaders.

Conclusion: The Future is Collaborative

In conclusion, Collaborative Robots have emerged as the driving force in the evolution of Automation Robotics for machine tending. Their ability to collaborate with humans, adapt to diverse tasks, and enhance overall efficiency signifies a paradigm shift in industrial automation. The future indeed belongs to a harmonious collaboration between man and machine, where innovation and efficiency converge to shape the industries of tomorrow.

No comments yet