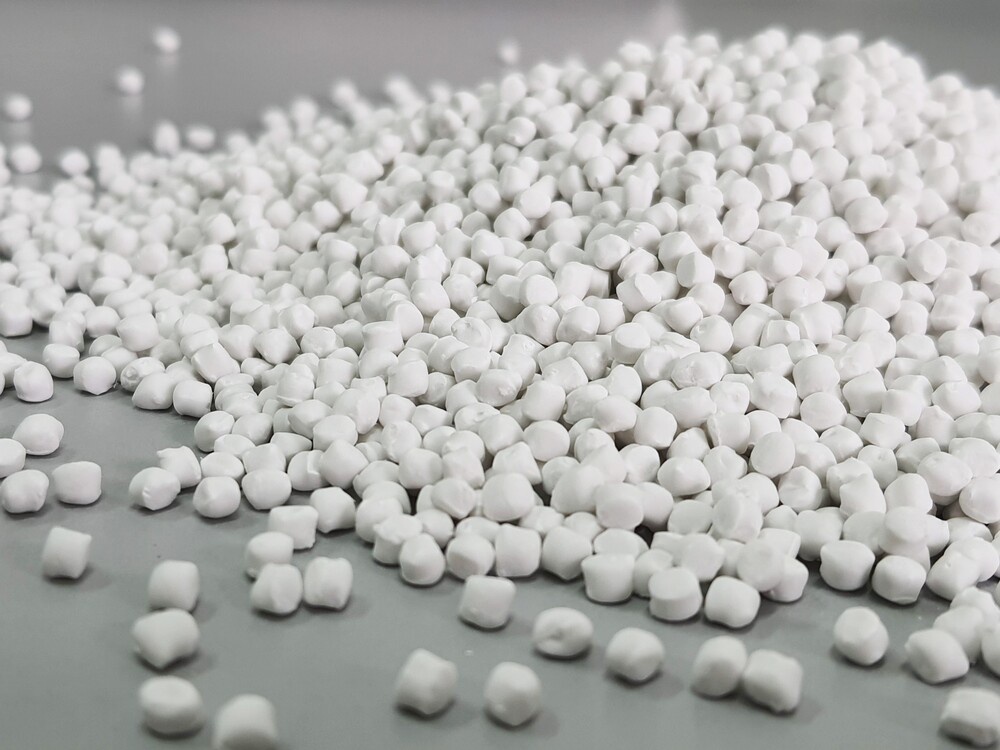

Filler masterbatches play a vital role in enhancing the properties and reducing the cost of plastic products. Comprising a carrier resin and high concentrations of additives, filler masterbatches are extensively used in various industries. From improving strength to achieving desired colors, they serve diverse purposes.

Some common applications for filler masterbatches:

1. Packaging Industry: Filler masterbatches find extensive usage in the packaging industry. Whether it's flexible packaging films or rigid containers, they help enhance properties such as tensile strength, impact resistance, and barrier properties. Moreover, they aid in reducing the overall cost of packaging materials while maintaining quality.

2. Automotive Sector: In the automotive industry, where stringent performance requirements meet cost-efficiency concerns, filler masterbatches are a boon. They are utilized in manufacturing components like bumpers, dashboards, and interior trims. By incorporating fillers such as calcium carbonate or talc, these masterbatches improve stiffness, dimensional stability, and heat resistance of automotive parts.

3. Construction Materials: Filler masterbatches play a significant role in the construction sector, especially in the production of pipes, sheets, and profiles. By adding fillers like glass fibers or minerals, these masterbatches enhance mechanical properties, weather resistance, and durability of construction materials. They also facilitate cost reduction without compromising on quality.

4. Electrical and Electronics: The electrical and electronics industry demands materials with excellent electrical insulation properties and mechanical strength. Filler masterbatches are used in manufacturing cables, connectors, and housings for electronic devices. They improve flame retardancy, thermal conductivity, and resistance to environmental stress, ensuring safety and reliability.

5. Agriculture: In agriculture, where weather conditions and operational stresses are significant challenges, filler masterbatches contribute to the production of durable and efficient materials. Mulch films, irrigation pipes, and greenhouse components benefit from the incorporation of filler masterbatches, which enhance UV resistance, mechanical strength, and longevity.

Conclusion:

Filler masterbatches are indispensable in various industries, offering a cost-effective means to enhance properties and improve performance. From packaging and automotive to construction and agriculture, their versatility makes them a preferred choice for manufacturers striving to balance quality with affordability. As innovation continues to drive the development of new filler materials and formulations, the applications of filler masterbatches are poised to expand further, catering to evolving industry needs.

Kothari Polymers, a leading provider of filler masterbatches, stands at the forefront of this dynamic industry, offering high-quality solutions tailored to diverse applications. With a commitment to innovation and customer satisfaction, Kothari Polymers continues to redefine standards in the realm of filler masterbatches, contributing to the success of industries worldwide.

No comments yet