Introduction

Every car owner knows how vital a smoothly running engine is for the overall performance of their vehicle. The crankshaft position sensor plays a crucial role in ensuring the engine's proper functioning. When this sensor starts to malfunction, it can lead to various problems that affect the vehicle's performance. In this article, we will explore the symptoms of a faulty crankshaft position sensor and learn how to detect and resolve these issues effectively.

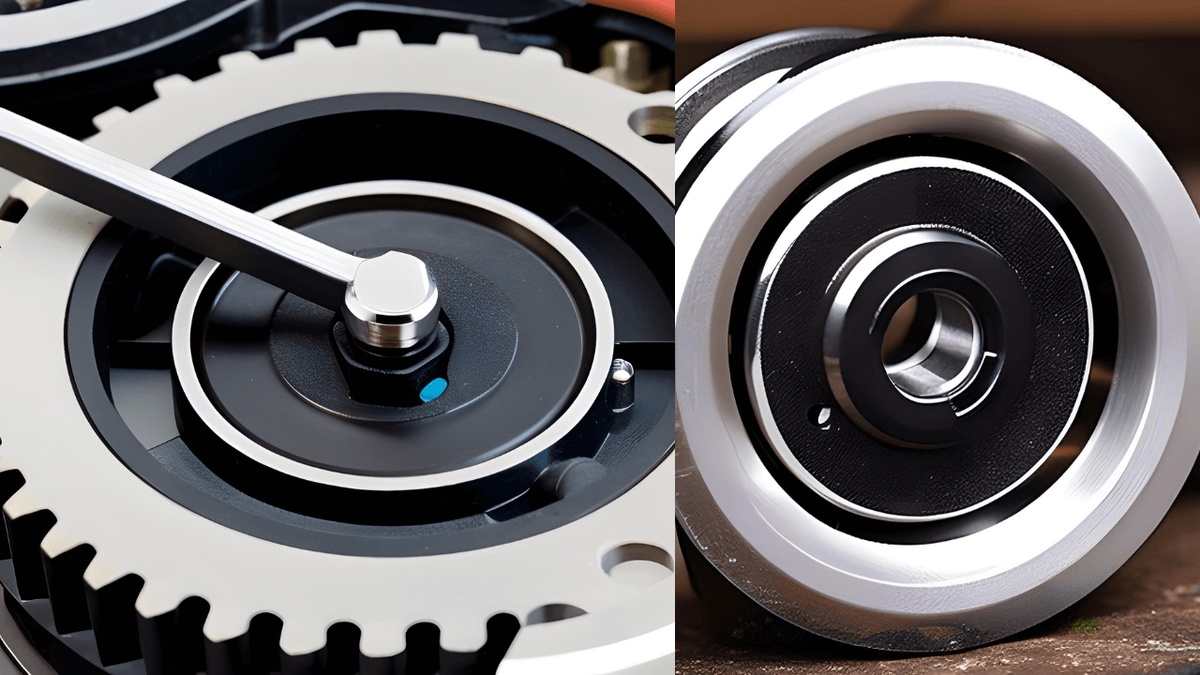

1. Understanding the Crankshaft Position Sensor

Before delving into the symptoms, it's essential to understand the role of the crankshaft position sensor. This sensor monitors the position and rotational speed of the crankshaft in the engine. It provides vital data to the engine control unit (ECU), enabling it to adjust the ignition timing and fuel injection. This synchronization is crucial for the engine to work smoothly and efficiently.

2. Common Symptoms of a Failing Crankshaft Position Sensor

When the crankshaft position sensor starts to fail, it can cause various issues that may initially go unnoticed. Here are some common symptoms to look out for:

2.1 Engine Stalling or Misfiring

A faulty crankshaft position sensor can cause intermittent engine stalling or misfiring. This happens because the ECU receives incorrect data, leading to improper fuel injection and ignition timing.

2.2 Difficulty Starting the Engine

One of the primary indicators of a failing sensor is difficulty starting the engine. If the sensor is not providing accurate data to the ECU, it can prevent the engine from starting altogether.

2.3 Rough Idling

A malfunctioning crankshaft position sensor can lead to rough idling or unstable RPMs. The engine may rev up and down or feel shaky when idling.

2.4 Drastic Drop in Fuel Efficiency

A drop in fuel efficiency is another sign of a faulty sensor. When the ECU receives incorrect data, it may supply more fuel than necessary, leading to increased fuel consumption.

2.5 Loss of Engine Power

A failing sensor can cause sudden power loss while driving. The ECU's inability to adjust the engine's timing and fuel injection can result in a decrease in engine power.

3. Diagnosing the Issue

If you notice any of the above symptoms, it's crucial to diagnose the problem accurately. Here's how you can do it:

3.1 OBD-II Scanner

Using an OBD-II scanner is the most efficient way to diagnose a faulty crankshaft position sensor. This device can read the error codes stored in the ECU and pinpoint the exact problem.

3.2 Visual Inspection

Perform a visual inspection of the sensor and its wiring harness. Look for signs of physical damage or loose connections.

3.3 Resistance Testing

You can also use a multimeter to test the sensor's resistance. Refer to your vehicle's service manual for the specific resistance values.

4. Replacing the Crankshaft Position Sensor

If the diagnosis confirms a faulty crankshaft position sensor, it's essential to replace it as soon as possible. Here's how you can do it:

4.1 Gather the Necessary Tools

Before starting, ensure you have the right tools for the job, including a socket set and a torque wrench.

4.2 Locate the Sensor

The sensor is usually located near the engine's crankshaft. Refer to your vehicle's service manual for the exact location.

4.3 Disconnect the Battery

Always disconnect the battery before working on any electrical components to avoid potential hazards.

4.4 Remove the Old Sensor

Carefully remove the old sensor, taking note of its position for proper installation of the new one.

4.5 Install the New Sensor

Securely install the new sensor and reconnect any disconnected wires.

4.6 Test the New Sensor

After installation, test the new sensor to ensure it's working correctly.

5. Conclusion

The crankshaft position sensor is a vital component of your vehicle's engine management system. Recognizing the symptoms of a failing sensor and taking prompt action can save you from more significant engine issues in the future. Regular maintenance and timely replacement of faulty sensors will keep your engine running smoothly and efficiently.

You can know more about crankshaft position sensor symptoms

No comments yet