In the ever-evolving landscape of thermal management, the quest for efficient heat dissipation has led to the rise of skived heat sinks, marking a paradigm shift in cooling technology. This article delves into the realm of skived heat sink manufacturing, exploring the excellence achieved by industry leaders in this cutting-edge field, without endorsing specific brands or companies.

Skived Heat Sink Technology: A Brief Overview:

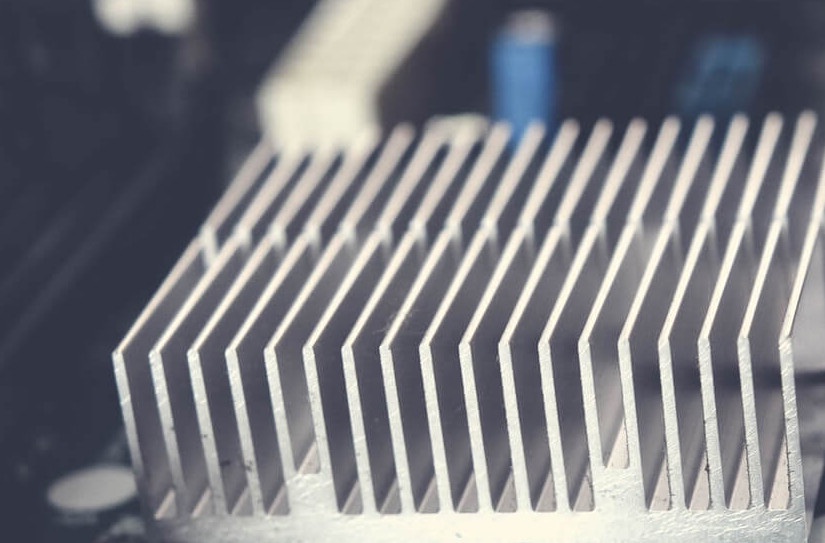

Skived heat sinks represent a cutting-edge approach to thermal management. Unlike traditional methods, skiving involves precision machining techniques where thin fins are sliced from a solid block of metal. This process creates intricate cooling fins with unparalleled precision, optimizing the surface area for efficient heat dissipation.

Precision Machining for Superior Cooling:

The heart of skived heat sink excellence lies in precision machining. Skiving allows manufacturers to achieve incredibly fine fin pitches and heights, resulting in a heat sink with an extensive surface area. This precision enhances the cooling efficiency of the heat sink, making it a formidable solution for dissipating heat from high-power electronic components.

Material Mastery in Skived Heat Sink Manufacturing:

Top manufacturers in the skived heat sink realm demonstrate material mastery by working with a variety of metals, including aluminum and copper. The choice of materials is crucial in achieving the right balance of thermal conductivity and durability. Skived heat sink excellence is characterized by the careful selection and machining of materials to ensure optimal thermal performance.

Efficiency in Every Slice:

Skived heat sink manufacturing excels in efficiency. The slicing process allows for the creation of intricate, multi-level fin structures that maximize the cooling surface area. This efficiency results in heat sinks that are not only highly effective but also lightweight and compact, making them ideal for applications where space is a critical consideration.

Customized Solutions for Varied Applications:

Skived heat sink excellence extends to the customization capabilities offered by top manufacturers. These industry leaders understand the unique thermal challenges faced by different sectors, from consumer electronics to industrial machinery. The adaptability of skived heat sink technology ensures that solutions can be tailored to meet the specific cooling needs of diverse applications.

Rigorous Quality Standards:

Achieving excellence in skived heat sink manufacturing requires adherence to rigorous quality standards. Top manufacturers implement thorough testing processes to ensure that each heat sink meets industry benchmarks. Consumers can rely on the fact that products from these leaders have undergone stringent testing for optimal heat dissipation and reliability.

As we explore the cutting-edge realm of skived heat sink excellence, it becomes evident that this technology is at the forefront of precision cooling solutions. The marriage of precision machining, material mastery, and efficiency in skived heat sink manufacturing positions it as a key player in the future of thermal management. As electronic devices continue to advance, the excellence achieved by skived heat sink leaders promises a cooler, more efficient future across a spectrum of industries.

No comments yet