In the present cutthroat assembling scene, boosting creation line proficiency is vital for keeping an upper hand. Proficiency upgrades efficiency as well as diminishes costs and works on overall quality. Executing procedures to upgrade creation line effectiveness can prompt critical additions in result and productivity. Here are a few significant hints to smooth out your production cycles and increase proficiency:

Invest in Automation and Technology

Putting resources into automation and innovation can essentially upgrade creation line effectiveness. Mechanized frameworks can perform redundant errands with accuracy and speed, lessening the requirement for difficult work and limiting the gamble of blunders. Consolidating trend setting innovations such as advanced mechanics, man-made consciousness, and Internet of Things (IoT) gadgets can additionally smooth out activities and further develop dynamic cycles. Also, moving up to present-day hardware and gear with improved abilities can increment throughput and limit downtime, enabling manufacturers to stay ahead in today's fast-paced market environment.

Streamline Workflow Processes

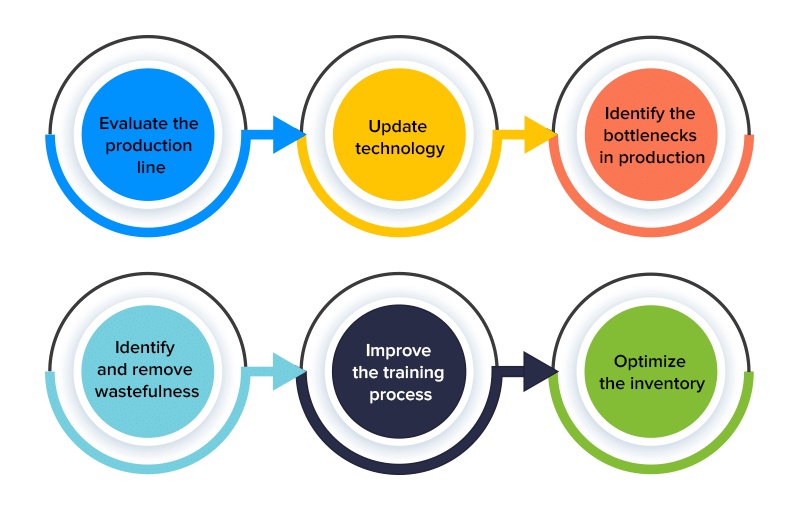

Streamlining workflow procedures is an essential step in increasing production line efficiency. Break down the whole presentation process beginning to end to distinguish bottlenecks, redundancies, and shortcomings. By upgrading work processes, you can dispense with pointless advances, diminish holding up times, and guarantee a smoother stream of tasks. Use strategies such as value stream mapping to picture the creation interaction and recognize regions for development. Carrying out lean assembling standards can likewise help in disposing of waste and working on general effectiveness.

Implement Effective Maintenance Practices

Customary upkeep of hardware and gear is fundamental for guaranteeing ideal execution and forestalling expensive breakdowns. Carrying out a proactive support timetable can assist with distinguishing likely issues before they heighten, limiting free time and exorbitant fixes. Predict equipment failures and schedule maintenance tasks accordingly by utilizing predictive maintenance methods like condition monitoring and vibration analysis. Effective remote vibration monitoring systems can provide real-time insights into the health of machinery, allowing for timely interventions and preventive measures.

Train and Empower Employees

Workers assume a pivotal part in the productivity of creation lines. Giving complete preparation projects can engage employees to work apparatus well, investigate issues, and streamline creation processes. Empower a culture of nonstop improvement where workers are effectively engaged with distinguishing valuable opportunities for upgrading and executing arrangements. You can improve productivity and efficiency in manufacturing by instilling a sense of ownership and accountability among your employees. Moreover, laying out clear correspondence channels and empowering cooperation among colleagues cultivates a feeling of brotherhood and shared liability, further encouraging everyone and boosting efficiency.

Monitor Performance and Continuously Improve

Checking execution measurements is fundamental for distinguishing areas of progress and estimating the adequacy of carried out methodologies. Track key execution pointers (KPIs) such as throughput, process duration, and deformity rates to measure creation line effectiveness precisely. Consistently dissect information and execution patterns to distinguish examples and regions for streamlining. Carry out an arrangement of consistent improvement where input circles are laid out, and illustrations gained from previous encounters are utilized to refine processes further. You can ensure that production line efficiency remains at its highest levels by actively monitoring performance and looking for opportunities for improvement.

In conclusion, improving creation line proficiency is a multi-layered effort that requires a mix of vital preparation, interest in innovation, worker strengthening, and powerful support rehearses. By smoothing out work process processes, utilizing mechanization and innovation, engaging representatives, carrying out successful upkeep practices, and observing execution, makers can advance their creation lines for most extreme productivity and seriousness in the present powerful market scene. Embracing a culture of consistent improvement is critical to remaining on the ball and making feasible progress in assembling tasks.

No comments yet