From low-voltage distribution networks to high-voltage transmission systems, simple electrical appliances to next-generation sensitive electronic devices, or any form of commodities, chemical earthing has become an essential component of any electrically powered structures and infrastructures. The traditional methods of earthing that used salt and charcoal as additions to lower soil resistance and offer low-resistance earthing to electrical facilities are long gone.

Chemical earthing is a more sophisticated type of maintenance-free earthing that replaces the use of salt and charcoal in traditional earthing with superior ground-enhancing chemicals like backfill compound. This Chemical Earthing Pit can reduce ground resistance and easily achieves low-resistance earthing.

Where is Chemical Earthing used?

The foundation of all electrically connected structures, infrastructure, equipment, and networks is chemical earthing. Without any exceptions, it is a need for all electrical systems and anything about electricity and electrical systems.

Anywhere that electricity is used or present, including houses, offices, constructions, structures, universities, landmarks, manufacturing establishments, chemical plants, medical facilities server rooms, natural gas and petroleum facilities, armed forces sites, and security points, must have it.

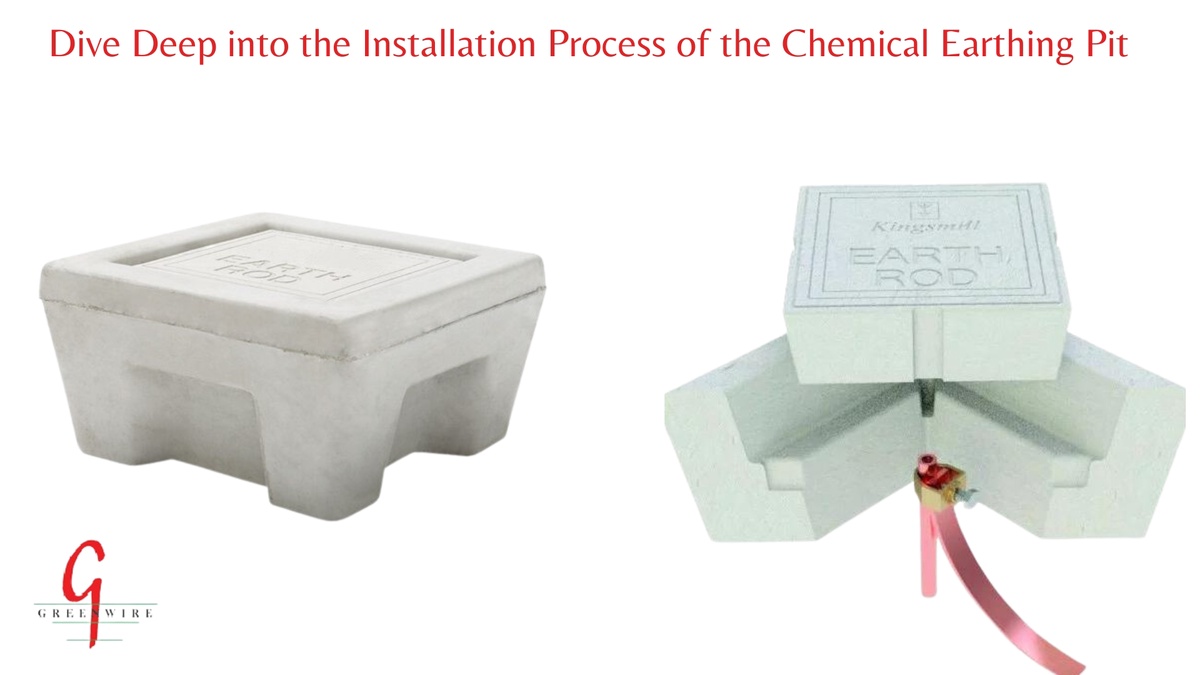

A Chemical Earth Pit: What Is It?

A Chemical Earthing Pit is a hole dug that is approximately 4-5 inches deep and ranges in depth from 1 to 3 meters, depending on the width and length of the earthing electrode. The purpose of the pit is to install the earthing electrode and fill it with ground enhancement compound, also called backfill compound, inside the ground.

The Benefits of Chemical Earthing Pit Application:

- Lowers the soil's resistance

- It's referred to as maintenance-free earthing since it doesn't require water, unlike earthing that uses coal and salt.

- We have steady on-earth resistance throughout the year thanks to chemical earthing, which prolongs life.

Let's examine the benefits of chemical earthing in more detail.

- Service Free: Because this method keeps the moisture in the soil for a longer amount of time, it requires no additional water to be poured regularly like conventional earthing does.

- Reliability: In contrast to a typical copperplate or rod, the stability of an earthing pit material will not change over time, and the weather will have less of an impact on the electrode's resistance.

- Larger Space: By forming a conductive zone, the conductive compound increases the surface area available for dissipating peak current while simultaneously obtaining a stable reference point.

Simple Installation: It may be put in practically any type of soil, both indoors and outdoors. Facilities, whether new or old, need less time and space.

Dig a hole that is 10 inches in diameter and 6 feet deep to create chemical earthing. The hole must be made deeper by the electrode's length. Place the electrode into the opening. Remember that the termination needs to be erect as shown above. The ground line and the earthing electrode must be connected. Pour water and ground-enhanced compound into the soil hole. It is polite to prepare the combination of Ground Enhance Compound and water. Thus, this will lessen the resistance of the ground.

One of the most fascinating and popular objects of Greenwire Power Solutions Pvt. Ltd. is chemical earthing. It is necessary to anticipate some questions while considering earthing. You have also looked at Chemical Earthing Questions on those questions. In general, coal and salt are added to the electrode during earthing.

However, Chemical Earthing Pit does not serve that purpose. We covered the chemical earthing with chemical powder.

No comments yet