INTRODUCTION:

In the world of fashion, where trends come and go, Eastern garments stand as a timeless testament to the rich cultural heritage and artistic diversity of the East. From the vibrant fabrics to intricate designs, Eastern garments weave a tapestry that seamlessly blends tradition with contemporary elegance.

EXPERTIES:

Eastern Garments controls a highly technical and advanced knit garment manufacturing facility. Its prime function is to manufacture up to date, innovative and high quality knitted apparel products via state of the art machines and technology. The facility can produce 600,000 garments per day. Our customer includes HBI, Champion, Alternatives, Under Armour, Gear for Sports, 47 Brand, Fanatics, Russell Athletic, Dickies, Carrefour etc.

Kniting

Our knitting units produce single knit, double knit, 2-end and 3-end fleece, single knit jacquards, auto and engineered stripes, Single knit circular machines from 17” to 30” diameter (all convertible to fleece), double knits pattern machines, flat knits including plain and jacquard, wide range of textures from 14 gauge to 28 gauge.

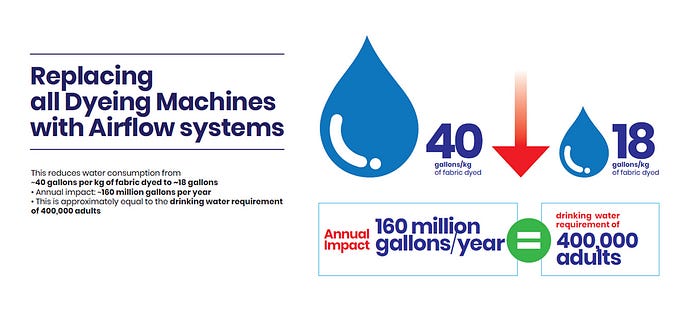

Dyeing

Eastern garments holds a production capacity of 20 metric tons per day for cotton and 5 metric tons for synthetics. We possess high capacity Sclavos, Brazoli and Fongs dyeing machines capable of handling up to 2200 lbs. per batch. We possess both air flow and water flow machines. We have exceptional shade-band continuity with minimum number of batches per year and have a state of the art and fully equipped lab support. Perfect colors are achieved through color prediction and color correction technology by Data color spectrophotometers.

Fabrication

While rooted in tradition, Eastern garments have successfully adapted to the demands of the modern world. Contemporary designers are incorporating traditional elements into their creations, resulting in a fusion of the old and the new. This synergy has given rise to outfits that capture the essence of Eastern heritage while catering to the tastes of a global audience.

Cutting

Our knitting units produce single knit, double knit, 2-end and 3-end fleece, single knit jacquards, auto and engineered stripes, Single knit circular machines from 17” to 30” diameter (all convertible to fleece), double knits pattern machines, flat knits including plain and jacquard, wide range of textures from 14 gauge to 28 gauge.

Sewing

Eastern Garments sewing department is equipped with cutting-edge electronic technology and the equipment that is required to produce high quality consumer goods. Our switch track garment-handling system is functioned to increase the maximum rate of production and to decrease startup and cycle times. We guarantee utmost level of productivity and efficiency through our hourly production monitoring system. Our sewing production unit is designed to handle assorted articles from very small to very large product line with maximum flexibility in order size to its optimum capacity.

Garment Dyeing

Our Washing facility is equipped with state-of-the-art laundry equipped with the latest machines, and for various washing effects.The facility is capable of normal garment washing, Resin, Coating, Baking, Pigment Dyeing, Garment Dyeing, Water-Saving Bleach Processes, Fading Methods, Randomized Washes, and Plenty of Other Techniques.

Embellishment

Eastern garments have highly developed technology in the field of embellishment. We are the pioneer of laser-cutting technology for tackle-twill, felt and chenille applique decorations in Pakistan. We are capable of successfully handling hundreds of SKUs per season with absolute precision and control. We also provide in-house digitizing and development expertise at our Design Head Quarters. We possess embroidery, circular printing, heat transfers, table printing facilities.

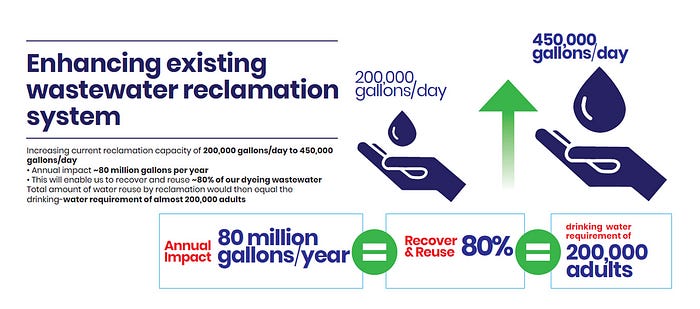

SUSTAINABILITY INACTIVITIES:

Eastern garments regularly produce variety of unmatched, unique and trendy collection of denim jeans, jerseys, denim knits; such as hoodies, jeggings, polo shirts and crew necks for men, women and children according to international standards. Our exclusive product range promises the consumer comfort, luxury and premium quality and furthermore gives them the sense of satisfaction and aesthetics so they can rise and shine in every way of life.

QUALITY ASSURANCE PROCESS:

State-of- the-art workrooms assure maximum productivity at every stage to achieve higher quality and superior products. Statistical process control (SPC) methods are employed in order to monitor and control all the processes so the company can operate at its full potential. Global methods and certifications of quality control like JC Penney Quality Assurance System, Parallel Management System for Production and Quality Assurance, On-line Quality Information System and In-House Audit Team maintain the equilibrium between the manufacturer and the consumer allowing us to produce excellent textile products.

Quality Control

Through a strict regimen of quality checks & controls, we maintain consistency in the quality of raw materials procured, in the quality of our manufacturing work, in packaging, in Shipment & Service etc.

Lab Testing

Laboratories are an extremely valuable component of our services and also facilitate the manufacturers — exporters & importers to conduct their business with the least quality risk. Our laboratory service includes.

Pre Production Check

First finished products are checked against buyer’s specifications and a prototype sample. Deviations areidentified and corrected.

Final Inspection

Final Inspection is based on specification of the buyers and it cover criteria such as design/ style, shrinkage, accessories, marking, colors, labeling, material, etc.

CONCLUTION:

Eastern Garments is a global manufacturer and exporter of private label apparel products for men, women and children. Since its inception in 1976, the Company has continually strived to create products that follow a body before-fabric philosophy, placing equal emphasis on comfort, aesthetics and quality.

No comments yet