In the realm of non-destructive testing (NDT), eddy current testing has emerged as a pivotal technique for evaluating the integrity of materials without causing damage. Recognising the significance of mastering this advanced technology, RVS Quality Certifications Pvt Ltd., a leading ISO Certification Training and Consultant, introduces comprehensive Eddy Current Training Courses. In this exploration, we unveil the top three benefits that position Eddy Current Training as an invaluable resource for professionals seeking to elevate their inspection capabilities.

Unleashing the Power of Precision in Defect Detection:

At the heart of such training lies the pursuit of precision in defect detection. Eddy current testing is renowned for its ability to identify and characterise flaws, cracks, and defects in conductive materials with exceptional accuracy. We recognise the critical role of precision in defect detection, particularly in industries where safety and reliability are paramount.

Through structured training, professionals gain an in-depth understanding of the principles behind eddy current testing. They learn to interpret the subtle variations in electrical currents induced in conductive materials, allowing them to pinpoint defects and irregularities. This skill at finding defects with great accuracy is very useful in fields like aerospace, automotive, and manufacturing, where parts are closely examined to make sure they meet safety and quality standards.

Enhanced Versatility for Diverse Material Applications:

These courses transcend the conventional boundaries of defect detection by emphasising the enhanced versatility of eddy current testing across diverse material applications. This non-destructive testing technique is not limited to a specific material type and can be applied to a wide range of conductive materials, including metals and alloys.

Professionals undergoing eddy current training gain the expertise to adapt the technique to various materials encountered in their respective industries. Whether testing the integrity of aerospace components, automotive parts, or industrial structures, the versatility of eddy current testing becomes a valuable asset. The ability to apply this technique across diverse materials ensures that professionals are equipped to meet the evolving needs of industries where materials vary in composition and conductivity. Elevating inspection capabilities through such training stands as a transformative step for professionals engaged in Non-Destructive Testing Services.

As industries continue to demand higher standards of quality, safety, and efficiency, professionals equipped with Eddy Current training become invaluable assets. RVS Quality Certifications Pvt. Ltd. invites individuals and organisations to explore the possibilities unlocked by Eddy Current Training, where precision, versatility, and efficiency converge to redefine the boundaries of non-destructive testing. Embrace the future of inspection capabilities with the mastery of eddy current testing, positioning yourself at the forefront of excellence in the dynamic world of material evaluation.

Real-Time Inspection Efficiency with Advanced Instrumentation:

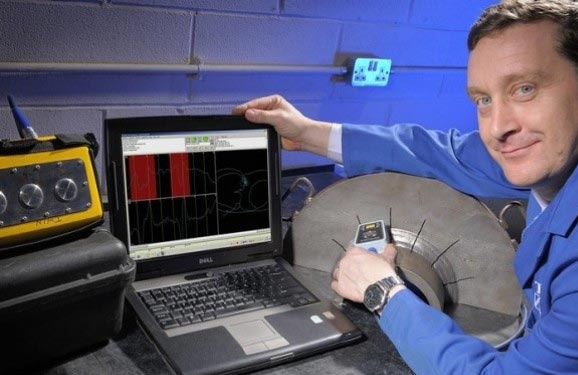

The emphasis on real-time inspection effectiveness, made possible by advanced instrumentation, is a distinguishing feature of training. Eddy current testing instruments have changed over time to include more advanced features that make inspections easier and give instant results and full data analysis.

Professionals undergoing Eddy Current Training learn to operate state-of-the-art instruments, gaining hands-on experience in real-world scenarios. The advanced instrumentation enables them to conduct inspections more efficiently, making quick and informed decisions based on real-time data. This efficiency is especially crucial in industries where downtime is minimised and rapid inspection is essential for maintaining operational continuity.

No comments yet