Edge banding is a crucial technique in woodworking that involves covering the exposed edges of wood panels or boards with a thin strip of material to create a seamless and finished appearance. Whether you're a seasoned woodworker or a beginner DIY enthusiast, mastering the art of edge banding can elevate the quality of your projects. In this comprehensive guide, we'll explore everything you need to know about edge banding, from its types and materials to step-by-step instructions and expert tips for achieving flawless finishes.

Introduction to Edge Banding

What is Edge Banding?

Edge banding, also known as edge veneer or edge trim, is the process of applying a thin strip of material to the exposed edges of wood panels or boards. This technique not only enhances the aesthetic appeal of the finished product but also provides protection against moisture, impacts, and wear.

Importance of Edge Banding in Woodworking

Edge banding serves both functional and aesthetic purposes in woodworking. By concealing the raw edges of wood panels, it prevents moisture infiltration and prolongs the lifespan of the furniture or cabinetry. Additionally, it adds a polished and professional look to the final product, making it more visually appealing.

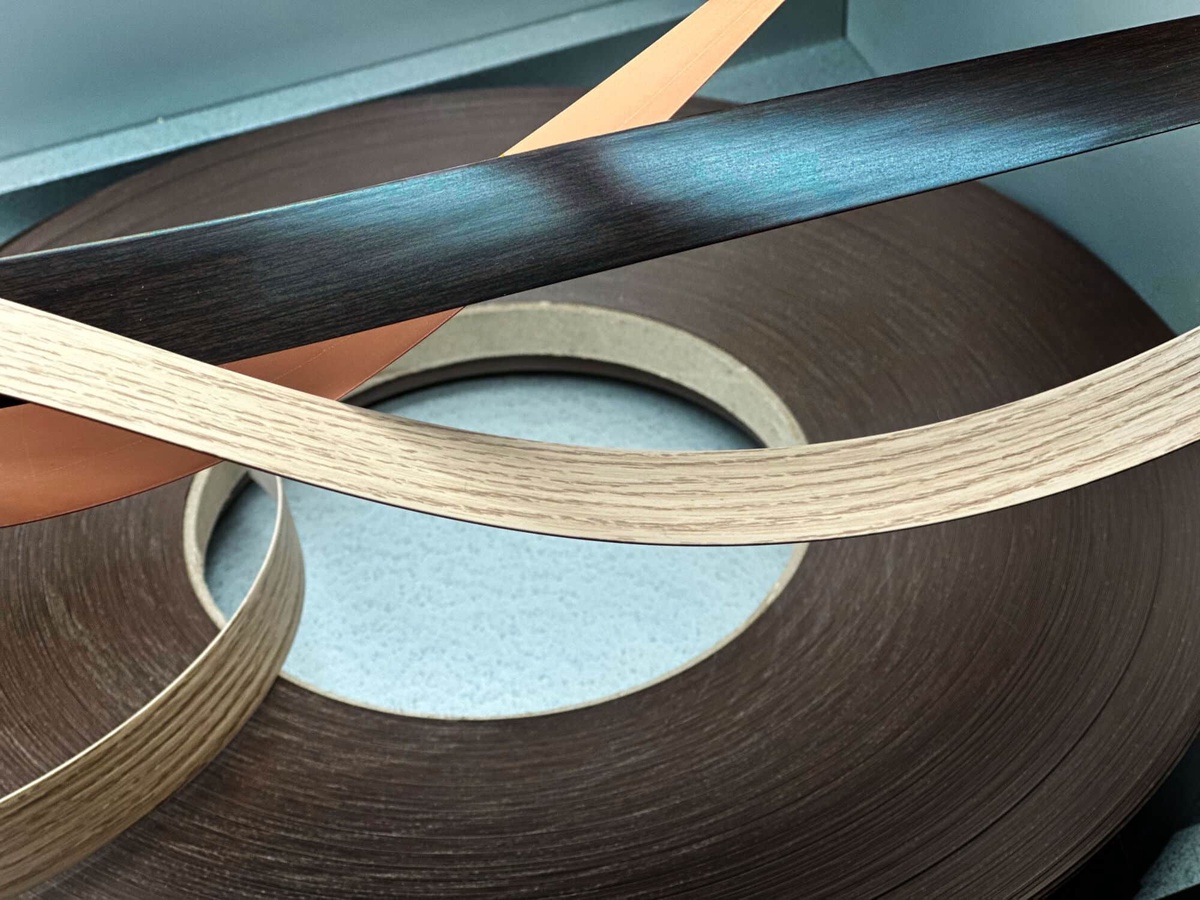

Types of Edge Banding

There are several types of edge banding materials available, each offering unique advantages and suitable for different applications:

Pre-glued Edge Banding

Pre-glued edge banding comes with a heat-activated adhesive applied to one side. It is easy to apply by simply ironing it onto the edge of the substrate, making it ideal for DIY projects and small-scale woodworking tasks.

Iron-on Edge Banding

Iron-on edge banding requires the use of a household iron to activate the adhesive and bond the banding to the edge of the panel. This type offers a strong and durable bond and is available in various widths and colors to suit different design preferences.

Peel-and-Stick Edge Banding

Peel-and-stick edge banding features a self-adhesive backing that allows for quick and hassle-free installation. It is an excellent choice for projects where time is of the essence or for covering curved or irregular edges.

Materials Used in Edge Banding

Edge banding materials come in a variety of options, including:

Wood Veneer

Wood veneer edge banding offers a natural and authentic look, making it popular for high-end furniture and cabinetry. It is available in a wide range of wood species and can be stained or finished to match the substrate perfectly.

PVC

PVC edge banding is known for its durability and resistance to moisture, making it suitable for applications in kitchens, bathrooms, and other high-moisture environments. It is available in a plethora of colors and finishes, including matte, glossy, and textured surfaces.

ABS

ABS edge banding combines the benefits of both wood veneer and PVC, offering excellent durability and a wide range of design options. It is resistant to scratches, impacts, and chemicals, making it ideal for commercial and industrial applications.

Tools Required for Edge Banding

To achieve professional results in edge banding, you'll need the following tools:

Edge Banding Trimmer

An edge banding trimmer is used to trim excess banding material flush with the surface of the panel, ensuring a seamless finish. It features a sharp blade that cuts through the banding cleanly without damaging the substrate.

Edge Banding Roller

An edge banding roller is used to apply pressure to the banding, ensuring proper adhesion to the substrate. It helps to eliminate air bubbles and ensures a strong bond between the banding and the panel.

Edge Banding Cutter

An edge banding cutter is used to trim the ends of the banding material at precise angles, allowing for seamless joins between adjacent pieces of banding. It ensures clean and professional-looking corners without any overhang or gaps.

Step-by-Step Guide to Edge Banding

Preparation of the Surface

Before applying edge banding, it's essential to prepare the surface of the panel by sanding it smooth and removing any dust or debris. This will ensure better adhesion and a seamless finish.

Application of Edge Banding

Bespoke Joinery and Board Cutting, Start by cutting the edge banding slightly longer than the edge of the panel using a sharp utility knife or scissors. Then, align the banding with the edge of the panel and apply pressure to bond it in place.

Trimming the Excess

Once the banding is securely attached, use an edge banding trimmer to trim off the excess material flush with the surface of the panel. Work slowly and carefully to achieve clean and precise cuts.

Tips for Achieving Flawless Finishes

Proper Alignment

Ensure that the edge banding is aligned perfectly with the edge of the panel to achieve a seamless and professional-looking finish. Use a straightedge or a carpenter's square to maintain straight lines and consistent widths.

Using the Right Tools

Invest in high-quality edge banding tools to achieve professional results consistently. Sharp blades, sturdy rollers, and precise cutters will make the edge banding process more efficient and enjoyable.

Applying Even Pressure

Apply uniform pressure when bonding the edge banding to the panel to ensure a strong and durable bond. Use a roller to apply pressure evenly across the surface, paying attention to the edges and corners.

Common Mistakes to Avoid

Poor Surface Preparation

Skipping or rushing through the surface preparation process can lead to adhesion issues and poor-quality finishes. Always take the time to sand the surface smooth and remove any dust or debris before applying edge banding.

Incorrect Application Technique

Applying too much or too little pressure when bonding the edge banding can result in uneven adhesion and unsightly gaps or wrinkles in the banding. Follow the manufacturer's instructions carefully and use the recommended techniques for applying and trimming the banding.

Ignoring Temperature and Humidity

Temperature and humidity can significantly affect the performance of adhesive-based edge banding materials. Avoid applying edge banding in extreme conditions, as high temperatures can cause the adhesive to dry too quickly, while high humidity can interfere with adhesion.

Benefits of Edge Banding

Enhanced Durability

Edge banding not only enhances the appearance of wood panels but also adds a layer of protection against wear, impacts, and moisture. By sealing the edges, it helps prevent delamination and extends the lifespan of the finished product.

Aesthetic Appeal

The seamless and finished look achieved with edge banding adds a touch of sophistication to furniture, cabinets, and other woodworking projects. It allows for creative design possibilities, such as contrasting or matching banding colors and textures.

Protection Against Moisture

Exposed edges are vulnerable to moisture infiltration, which can cause swelling, warping, and degradation of the substrate. Edge banding creates a barrier that seals out moisture, keeping the underlying material safe and intact.

Applications of Edge Banding

Edge banding is widely used in various woodworking applications, including:

- Furniture Manufacturing: From tables and chairs to cabinets and shelving units, edge banding is essential for creating clean and polished edges in furniture construction.

- Cabinet Making: Kitchen cabinets, bathroom vanities, and storage cabinets benefit from the added durability and aesthetic appeal provided by edge banding.

- Interior Design Projects: Edge banding allows interior designers to customize furniture and architectural elements with seamless edges that complement the overall design aesthetic.

Edge Banding Services for Professionals

While DIY enthusiasts can certainly tackle edge banding projects on their own, professional Edge Banding Services offer several advantages, including:

- Expertise and Experience: Professional edge banding technicians have the knowledge and experience to handle complex projects with precision and efficiency.

- Quality Assurance: Professional edge banding services use high-quality materials and equipment to ensure consistent results and superior craftsmanship.

- Time and Cost Savings: Outsourcing edge banding tasks to professionals saves time and eliminates the need to invest in specialized tools and equipment.

Conclusion

Mastering the art of edge banding is essential for achieving flawless finishes in woodworking projects. By understanding the different types of edge banding materials, tools, and techniques, you can enhance the durability and aesthetic appeal of your creations. Whether you're a seasoned woodworker or a novice DIY enthusiast, incorporating edge banding into your projects will elevate the quality and professionalism of your work.

No comments yet