Introduction:

In the realm of concrete block manufacturing, efficiency is key to success. Every aspect of the process, from machinery to materials, plays a vital role in determining output quality and quantity. Among these components, pallets are fundamental. In this article, we'll explore the importance of pallets for concrete block machine, covering types like production boards, pallets, and hardwood pallets, and how they impact production.

Understanding the Significance of Pallets:

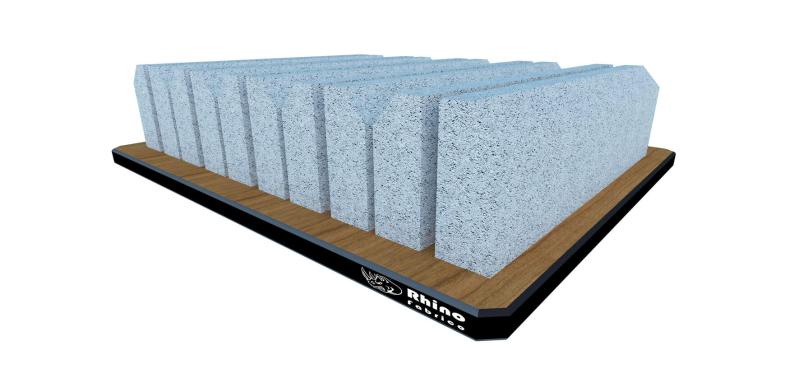

Pallets serve as foundational platforms for forming and curing concrete blocks within block making machines. They provide essential support during compaction and curing, ensuring uniformity and strength in the final product. The choice of pallets directly influences various aspects of production, including block quality, cycle time, and maintenance costs.

Types of Pallets for Concrete Block Machines:

Production Pallets: These production pallets are specifically engineered to withstand the rigorous demands of concrete block production. They endure high pressure and repeated use without warping or deteriorating, ensuring consistent block quality.

Hardwood Pallets: Renowned for their durability, hardwood pallets offer exceptional stability and longevity in high-volume production facilities.

Production Boards: These boards provide a flat and stable surface for block formation, enhancing precision and consistency in the manufacturing process.

Advancements in Pallet Technology:

The industry has witnessed significant advancements in pallet design and manufacturing processes. Modern pallet solutions incorporate advanced materials and engineering techniques to enhance performance and durability. Features like reinforced construction and surface treatments contribute to improved efficiency and extended lifespan, ultimately optimizing production outcomes.

Benefits of Upgrading to Advanced Pallet Solutions:

Enhanced Durability: Advanced pallets withstand harsh conditions, ensuring prolonged service life and reduced maintenance requirements.

Optimized Performance: Stable support minimizes block deformities, increasing production efficiency and lowering operating costs.

Environmental Sustainability: Composite pallets offer a sustainable alternative, reducing waste and promoting resource conservation.

Customization Options: Tailored pallet specifications suit unique production requirements, ensuring compatibility with various block making machines.

Key Considerations for Selecting Pallet Solutions:

Compatibility: Choose pallets compatible with the specific requirements of your concrete block machine, considering size and weight capacity.

Durability: Prioritize pallets with superior resistance to wear and tear, especially in high-intensity production environments.

Cost-effectiveness: Evaluate long-term benefits against upfront costs to ensure a sound investment.

Sustainability: Opt for eco-friendly options that minimize environmental impact and promote circular manufacturing practices.

Conclusion:

In the dynamic landscape of concrete block production, pallets play a crucial role. Embracing advanced pallet solutions is essential for maximizing efficiency, quality, and sustainability. Whether opting for traditional hardwood pallets for concrete block machine or innovative composite alternatives, manufacturers can gain significant advantages by investing in pallets tailored to their production needs. By prioritizing durability, performance, and environmental responsibility, concrete block manufacturers pave the way for a more resilient and efficient future.

#PalletsConcreteBlockMachine #ProductionBoardsConcreteBlockMachine #ProductionPallets #HardwoodPalletsConcreteBlockMachine #ProductionPalletConcreteBlocks

No comments yet