Cleanrooms are essential in a variety of industries, including pharmaceuticals, biotechnology, electronics, and healthcare. These controlled environments require strict regulations to keep contaminants at bay and ensure the quality and safety of the products being produced. One technology that has revolutionized cleanroom construction is the use of sandwich panels.

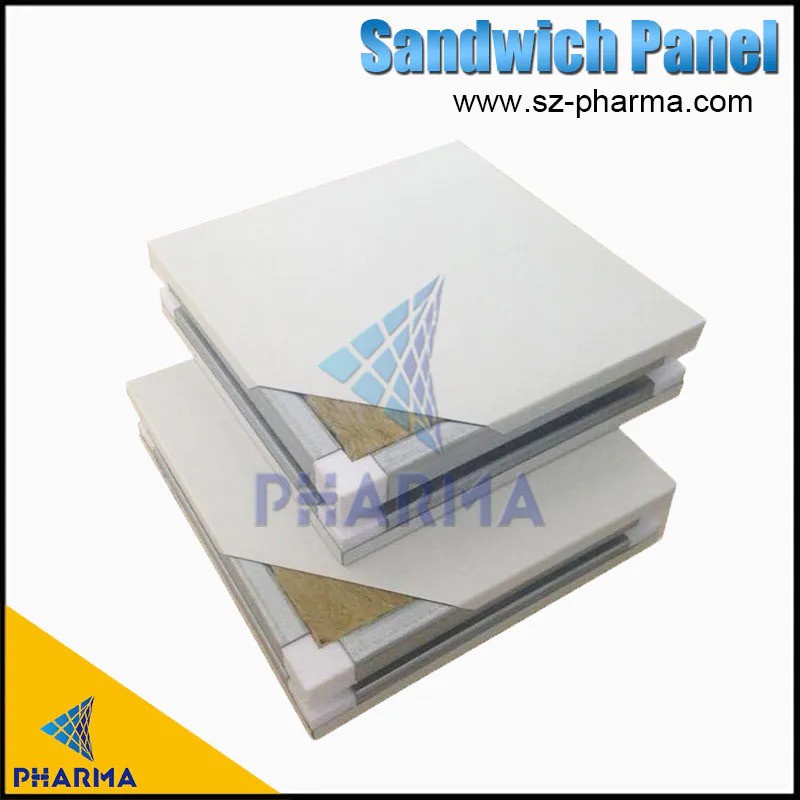

Structure and Composition

Sandwich panels consist of two outer layers (typically made of metal or composite materials) with a core material in between. This core material can vary depending on the specific needs of the cleanroom, with options such as foam, honeycomb, or mineral wool. The combination of these layers provides a strong and durable structure that is also lightweight and easy to install.

Thermal Insulation Properties

One of the key benefits of using sandwich panels in cleanroom construction is their thermal insulation properties. Cleanrooms often require precise temperature control, and sandwich panels provide excellent insulation to help maintain the necessary temperature levels. This not only ensures the comfort of workers inside the cleanroom but also protects sensitive equipment and products from temperature fluctuations.

Sound Insulation

In addition to thermal insulation, sandwich panels also offer superior sound insulation. Cleanrooms can be noisy environments, with equipment running constantly and workers moving about. By using sandwich panels with sound-insulating properties, the noise levels within the cleanroom can be significantly reduced, creating a more comfortable and productive working environment.

Fire-Resistant Properties

Another advantage of sandwich panels is their fire-resistant properties. In industries where flammable materials are present or in close proximity to the cleanroom, fire safety is a top priority. Sandwich panels with fire-resistant cores can help provide an extra layer of protection in the event of a fire, minimizing damage and ensuring the safety of workers inside the cleanroom.

Modular and Customizable

The modular nature of sandwich panels also allows for quick and easy installation, saving time and reducing construction costs. With traditional construction methods, building a cleanroom can be a lengthy and complex process. However, sandwich panels can be prefabricated off-site and then assembled on-site, speeding up the construction process and minimizing disruptions to ongoing operations.

Highly Customizable

Furthermore, sandwich panels are also highly customizable, allowing for flexibility in cleanroom design. Whether you need specific colors, finishes, or configurations, clean room sandwich panel can be tailored to meet your unique requirements. This customization not only enhances the aesthetic appeal of the cleanroom but also allows for efficient use of space and resources.

Conclusion

Overall, the use of sandwich panels in cleanroom construction offers a wide range of benefits that can significantly enhance the efficiency and effectiveness of the cleanroom environment. From thermal and sound insulation to fire resistance and quick installation, sandwich panels are a versatile and cost-effective solution for creating high-quality cleanrooms in a variety of industries. By harnessing the advanced technology of sandwich panels, companies can achieve superior cleanliness standards and provide a safe and productive working environment for their employees.

No comments yet