Introduction

In the world of packaging and printing, dielines play a crucial role. They are the blueprint or template that defines the exact shape and size of a package before it is manufactured. Dielines ensure precision in the packaging process and allow designers to visualize how the final product will look. In this article, we will delve deep into the concept of dielines, their significance in the packaging industry, and how they contribute to creating functional and attractive packaging solutions.

What is a Dieline?

1.1 Understanding Dielines in Packaging

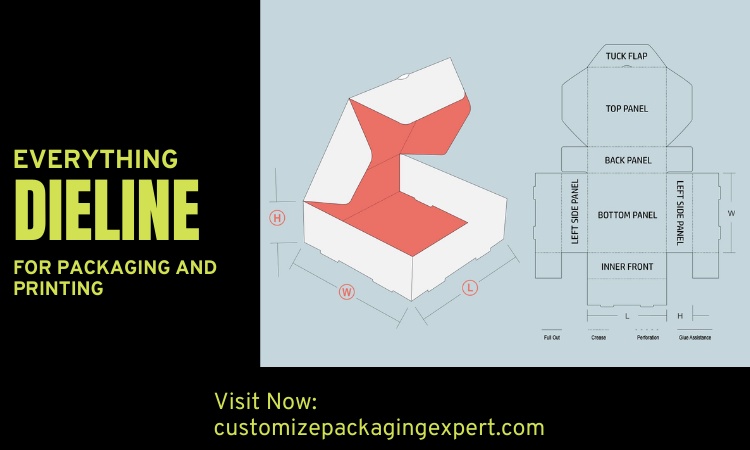

A dieline is a two-dimensional outline or template that represents the shape and size of a package. It serves as the foundation for designing and manufacturing packaging materials. Designers create dielines before proceeding with the actual artwork, allowing them to visualize the structure of the package accurately. Dielines are essential in ensuring that the final product meets the desired specifications and functions optimally.

1.2 Importance of Dielines in Printing

In the printing process, dielines are used to create print-ready files. They provide essential guidelines for printers to cut, fold, and assemble the package accurately. Dielines guarantee that the design aligns correctly with the package, reducing errors and minimizing material wastage during production.

Types of Dielines

2.1 Straight Tuck End Dieline

The straight tuck end dieline is one of the most common types of dielines used in packaging. It features a straightforward design with both ends of the package tucked in. This dieline is ideal for packaging that requires easy access and a clean, seamless appearance.

2.2 Reverse Tuck End Dieline

The reverse tuck end dieline is similar to the straight tuck end, but the ends of the package tuck in opposite directions. This design is often used for smaller retail items and pharmaceutical packaging.

2.3 Auto-Bottom Lock Dieline

The auto-bottom lock dieline offers a secure bottom closure, which automatically locks into place when the package is assembled. This dieline is commonly used for heavy or bulk items, providing added structural support.

2.4 Seal End Dieline

The seal end dieline features a tuck end on one side and a sealable flap on the other, offering a secure closure. This dieline is often used for food packaging, ensuring product freshness and preventing tampering.

Creating Dielines

3.1 Manual Dieline Design

In manual dieline packaging design, designers create the templates using traditional drafting tools like pencils, rulers, and paper. This approach requires precision and accuracy to ensure the dieline aligns perfectly with the final package.

3.2 Computer-Aided Dieline Design

Computer-aided dieline design involves using specialized software to create digital dielines. This method offers greater flexibility and efficiency, enabling designers to make quick adjustments and visualize the dieline in 3D.

Key Considerations for Dieline Design

4.1 Material Selection

The choice of material is crucial in dieline design. Different materials have varying levels of flexibility, sturdiness, and printability. Designers must select materials that suit the packaging requirements and enhance the overall appearance of the product.

4.2 Structural Integrity

Dielines must be structurally sound to ensure the package can withstand handling, transportation, and storage. Reinforcements like scores, perforations, and flaps are incorporated into the dieline to enhance its strength and stability.

4.3 Printing Techniques and Finishes

Consideration of printing techniques and finishes is vital to achieve the desired visual impact. Dieline designs should accommodate the chosen printing method and finishing options, such as embossing, foiling, or varnishing.

How Dielines Facilitate Printing

5.1 Printing Methods Compatible with Dielines

Dielines play a significant role in guiding the printing process. They ensure the artwork aligns correctly with the package, preventing any misalignments that could occur during printing.

5.2 Print Finishing Techniques for Dielines

Various print finishing techniques can enhance the visual appeal and texture of packaging materials. Dieline designs should incorporate areas designated for these finishes to create eye-catching packaging.

Dielines in Different Industries

6.1 Food and Beverage Industry

In the food and beverage industry, dielines are used for a wide range of products, including cereal boxes, snack packages, and beverage containers. Dielines help in creating functional and appealing packaging that protects the contents and attracts consumers.

6.2 Cosmetics and Personal Care Industry

Cosmetics and personal care products rely heavily on creative and attractive packaging. Dielines enable designers to craft innovative packaging solutions that reflect the brand's identity and resonate with customers.

6.3 Electronics and Technology Industry

In the electronics and technology industry, dielines are used for packaging various devices and accessories. These dielines ensure the safety and protection of delicate electronics while also providing an aesthetically pleasing appearance.

Also Read: What is the Packaging Trend in Cosmetics 2023?

The Role of Dielines in Sustainable Packaging

7.1 Reducing Material Waste

Efficient dieline design can significantly reduce material waste during the production process. Minimizing excess material leads to a more sustainable and cost-effective packaging solution.

7.2 Enhancing Eco-Friendly Packaging Solutions

Dielines play a pivotal role in incorporating eco-friendly materials and designs into packaging solutions. Sustainable practices in dieline design contribute to reducing the environmental impact of packaging waste.

Best Practices for Dieline Implementation

8.1 Collaboration between Designers and Manufacturers

Effective collaboration between designers and manufacturers ensures seamless execution of the dieline design, leading to a successful and visually appealing end product.

8.2 Test Prints and Prototyping

Conducting test prints and creating prototypes allows designers to identify and address any issues with the dieline before full-scale production. This step helps in fine-tuning the design and achieving the desired results.

Common Dieline Design Errors to Avoid

9.1 Insufficient Bleed and Safety Margins

Insufficient bleed and safety margins can lead to issues during printing and finishing processes. Adequate margins should be included to avoid any unwanted cropping or misalignment.

9.2 Ignoring Perforation and Folding Lines

Overlooking perforation and folding lines can hinder the functionality of the package. Designers must ensure that these lines are accurately placed to create a seamless folding experience.

Advancements in Dieline Technologies

10.1 3D Rendering and Visualization

Modern dieline technologies allow designers to render and visualize packaging designs in 3D. This advancement aids in better understanding the final product and making necessary adjustments before manufacturing.

10.2 Interactive Dielines for Customer Engagement

Interactive dielines enable brands to engage customers through unique packaging experiences. Augmented reality (AR) and QR code-based dielines offer exciting interactions that leave a lasting impression on consumers.

Also Read: Eco-Friendly Cosmetic Packaging for Small Business

Future of Dielines in the Packaging Industry

11.1 Integration of Smart Technologies

With the rise of smart packaging, dielines will play a crucial role in integrating technology such as sensors and NFC tags into packaging solutions. This integration will enable functionalities like product tracking and authentication.

11.2 Customization and Personalization

The future of dielines lies in customization and personalization. Advanced dieline technologies will allow brands to create packaging tailored to individual customer preferences, enhancing brand loyalty and consumer satisfaction.

Conclusion

Dielines are the backbone of the packaging and printing industry. They ensure that every package is precisely designed and produced to meet the specific needs of the product and brand. From improving printing accuracy to enabling sustainable packaging practices, dielines are at the forefront of innovation and creativity. Embracing the potential of dielines and staying abreast of technological advancements will undoubtedly shape the future of packaging, making it more functional, sustainable, and visually captivating.

FAQs

Q1: What is the primary purpose of a dieline in packaging?

A1: The primary purpose of a dieline in packaging is to serve as a template or blueprint that defines the exact shape and size of a package before it is manufactured.

Q2: Can dielines be created manually?

A2: Yes, dielines can be created manually using traditional drafting tools. However, computer-aided dieline design offers greater flexibility and efficiency.

Q3: How do dielines contribute to sustainable packaging?

A3: Efficient dieline design reduces material waste during production, contributing to more sustainable and eco-friendly packaging solutions.

Q4: What are some common dieline design errors to avoid?

A4: Some common dieline design errors to avoid include insufficient bleed and safety margins, and overlooking perforation and folding lines.

Q5: What does the future hold for dielines in the packaging industry?

A5: The future of dielines in the packaging industry lies in integrating smart technologies and offering customization and personalization options to consumers.

No comments yet