Metal fabrication from ancient times makes weapons, armour, etc., from bronze using a smelting process. But from the 1960s, laser or light amplification by stimulated emission of radiation has become the best metal fabrication technique. It is because of its improvements in edge squareness, accuracy, and entire control of heat input.

Hence, laser metal fabrication is replacing many profiling cutting techniques like oxy-fuel, plasma, and others. Laser beams have high energy densities, over four trillion times more than the sun’s focused energy. The top component manufacturer uses CNC or computer numerical control laser machines for cutting, bending, and assembling.

The significant benefit of it is getting the precise laser cutting parts to be helpful in construction, automotive, aerospace, and other industries.

Continue reading this article until the end to learn about laser metal fabrication to make many laser cut bend metal parts from cutting sheet metals with high precision and accuracy for use in many industrial verticals.

What is laser metal fabrication?

Metal fabrication is a critical process for making many parts for various industries. Sheet metal, being a multifunctional material because of its versatility and ability to get processed easily, is now the most used for making many components in various forms and shapes. It helps make mobile phones, lockers, refrigerators many other accessories, mechanical parts, etc.

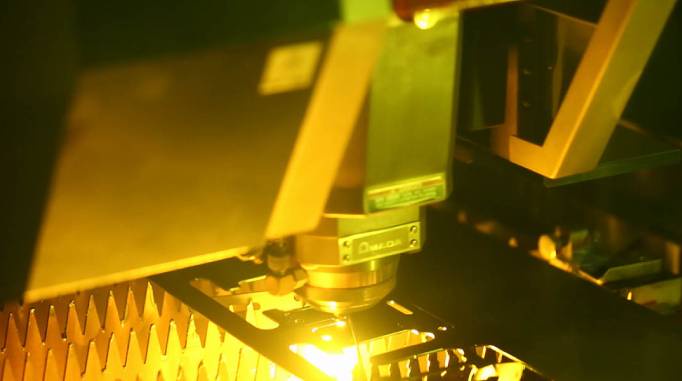

Laser metal fabrication for the past half a century revolutionized the industrial world by enabling the making of many parts with high precision and accuracy. It is a form of thermal cutting method using a focused high-power density laser beam to cut metals or steel sheets into many parts.

With many projects in several industries facing time and budgetary constraints, it is critical to use precise laser cut bend metal parts. Not only that, but the laser cutting technique provides laser-cut parts with high efficiency, flexibility, cost optimization, and superior quality. Also, using the CNC machines will avoid unnecessary errors, prevent material wastage, and save costs by streamlining production.

What are laser-cutting parts?

A vehicle has around 30,000 parts with high precision to fit and perform for its aesthetic look and smooth road running. For construction projects, numerous parts are involved for the buildings, bridges, and others to stay strong. Hence, laser-cut parts using CNC machines to control the high-density beams for clean and smooth cuts only need later post-cut processing.

With laser cutting, joining, and subtracting materials, they can even add them by laser metal deposition or 3-D printing. The top manufacturer can change pule frequencies, power levels, and energy densities to make high-quality, precise laser-cut bend metal parts.

Six Benefits of Laser Metal Fabrication

In the past fifty years, the laser has transformed industrial processes by solving many manufacturing problems by providing high-quality laser-cut parts. The experienced manufacturer uses many process variables like beam diameter and manipulation to cut, weld, and add or remove material layers.

The many laser technology advancements are creating a meaningful impact even on the Fourth Industrial Revolution in the 21st century. It is because of the many benefits of laser metal fabrication that include the following, among others.

1. Offers unmatched precision cutting with less heat-affected zones for making accurate laser cut parts with plus or minus 0.1mm accuracy

2. Provide highly efficient cutting with reduced effort or person-hours and minimize material waste to save costs.

3. It offers excellent flexibility, with no need for exchange tools for each separate cut not to have any intriguing issues.

4. Enables repeatability of cutting parts that are replicas of each other with plus or minus 0.05 mm precision

5. Provides quicker cutting or parts than all other mechanical methods, and thermal cutting methods like flame or plasma cutting

6. Reduces workforce by using automated laser-cutting machines to make laser-cut parts with high-precision

San Automotive is the leader in making laser cutting parts with high precision in its three state-of-the-art facilities.

No comments yet