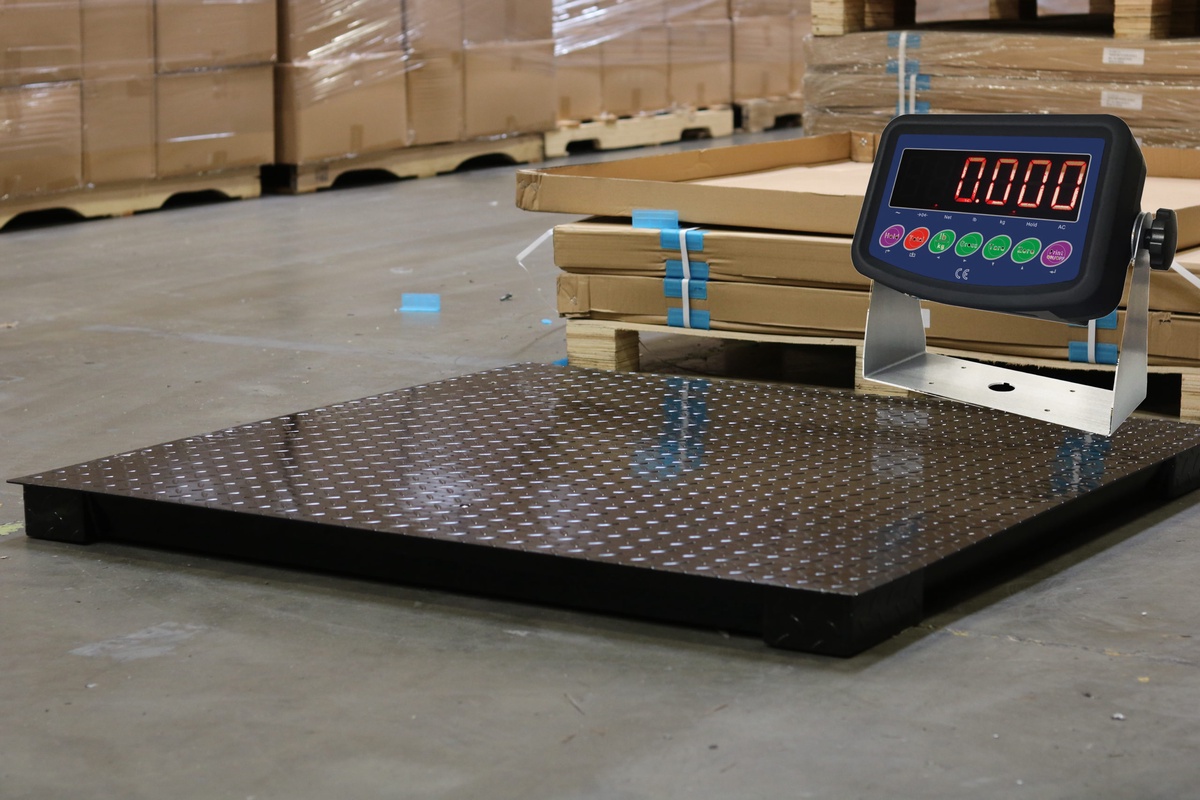

In the logistics and industrial world, precision and efficiency are paramount. When it comes to managing inventory and shipments, accurate weight measurement is essential. This is where pallet scales come into play. In this comprehensive guide, we'll delve into everything you need to know about pallet scale, including their accuracy, uses, how to weigh a pallet, and the significance of commercial scales.

Are Pallet Scales Accurate?

One of the most common questions surrounding pallet scales is their accuracy. Pallet scales are designed to provide precise weight measurements of palletized goods. When properly calibrated and maintained, pallet scales can offer highly accurate readings, ensuring that businesses can rely on them for crucial weight data in their operations. However, like any other measurement device, the accuracy of pallet scales can be affected by factors such as calibration frequency, environmental conditions, and proper usage.

What is a Pallet Scale Used For?

Pallet scales serve various purposes across different industries. Their primary function is to weigh palletized goods quickly and accurately. This weight data is essential for inventory management, shipping and receiving, quality control, and compliance with regulations. Pallet scales are commonly found in warehouses, distribution centers, manufacturing facilities, and shipping yards, where they play a crucial role in streamlining operations and optimizing logistics processes.

How Can I Weigh a Pallet?

Weighing a pallet using a pallet scale is a straightforward process that involves the following steps:

- Preparation: Ensure the pallet scale is calibrated and in proper working condition. Clear the scale platform of any debris or obstructions.

- Placement: Position the pallet scale in a flat, stable location. Carefully place the pallet loaded with goods onto the scale platform, ensuring it is centered and balanced to prevent inaccuracies.

- Recording: Once the pallet is securely positioned on the scale, wait for the weight reading to stabilize. Record the weight displayed on the scale indicator or digital display.

- Documentation: Document the weight measurement for record-keeping and reference purposes. Ensure accuracy by double-checking the recorded weight if necessary.

- Unload: After obtaining the weight measurement, carefully remove the pallet from the scale platform, ensuring safe handling of the goods.

By following these steps, businesses can effectively weigh pallets using pallet scales, facilitating efficient inventory management and logistics operations.

What is a Commercial Scale?

A commercial scale refers to a weighing device specifically designed for commercial and industrial applications. Unlike household scales used for personal weight measurement, commercial scales are built to withstand heavy-duty use and provide accurate weight readings for various purposes. Commercial scales come in a wide range of types and configurations, including pallet scales, floor scales, bench scales, and truck scales, each tailored to specific weighing needs in commercial settings.

Conclusion

Pallet scales are indispensable tools in the realm of logistics and industrial operations. From accurately weighing palletized goods to facilitating efficient inventory management and logistics processes, pallet scales play a crucial role in enhancing productivity and profitability for businesses. By understanding their accuracy, uses, and proper weighing procedures, businesses can harness the full potential of pallet scales to optimize their operations and stay ahead in today's competitive marketplace.

FAQ's

- Are pallet scales accurate?

Pallet scales are designed to provide accurate weight measurements of palletized goods. When properly calibrated and maintained, pallet scales can offer highly precise readings, ensuring reliable weight data for various applications in logistics and industrial settings.

- What is a pallet scale used for?

Pallet scales serve multiple purposes across different industries. Their primary function is to weigh palletized goods quickly and accurately. This weight data is essential for inventory management, shipping and receiving, quality control, and compliance with regulations.

- How can I weigh a pallet?

Weighing a pallet using a pallet scale is a straightforward process. First, ensure the scale is calibrated and in proper working condition. Then, position the pallet on the scale platform, wait for the weight reading to stabilize, record the measurement, and document it for reference. Careful handling and proper placement of the pallet ensure accurate weight readings.

- What is a commercial scale?

A commercial scale is a weighing device specifically designed for commercial and industrial applications. Unlike household scales used for personal weight measurement, commercial scales are built to withstand heavy-duty use and provide accurate weight readings for various purposes. Pallet scales are one type of commercial scale, tailored to weigh palletized goods efficiently.

No comments yet