In the dynamic world of manufacturing, where precision and efficiency are paramount, various techniques are employed to create high-quality products. One of the most versatile and widely used techniques is plastic injection molding. With its ability to produce intricate designs and complex shapes, plastic injection molding has revolutionized the manufacturing industry.

In this article, we will delve into the world of manufacturing techniques, with a special focus on plastic injection molding.

Understanding Plastic Injection Molding

Plastic injection molding is a manufacturing process that involves injecting molten plastic into a mold cavity. The process begins with the selection of the appropriate polymer resin, which is then heated and melted. The molten plastic is then injected into a specially designed mold, which shapes and cools the material. Once solidified, the molded part is ejected, and the cycle repeats.

The Advantages Of Plastic Injection Molding

Versatility: Plastic injection molding offers tremendous design flexibility, allowing for the creation of intricate and complex shapes that would be difficult to achieve with other techniques. This versatility makes it an ideal choice for various industries, including automotive, medical, consumer goods, point of sale branding, and electronics.

High Efficiency: Plastic injection molding is a highly efficient manufacturing process. The ability to produce multiple parts simultaneously, known as multi-cavity molding, drastically reduces production time and cost. Additionally, the automation of the process ensures consistent quality and reduces the margin of error.

Cost-Effectiveness: Once the initial investment in tooling and mold development is made, plastic injection molding becomes a cost-effective method for high-volume production. The ability to reuse molds for long production runs reduces per-unit costs, making it an attractive option for large-scale manufacturing.

The Advanced Techniques Of Injection Molding

Overmolding: Overmolding is a technique that involves molding one material over another to create a single, integrated part. This technique is widely used to improve product aesthetics, functionality, and grip.

For example, soft rubber grips on tools or handles can be overmolded onto rigid plastic components, enhancing ergonomics and user experience.

Insert Molding: Insert molding involves the placement of pre-fabricated metal or plastic inserts into the mold before the injection process begins. This technique enables the integration of additional features or reinforcement into the final product.

Common applications include adding threaded inserts, electrical contacts, or metal reinforcements to plastic parts, resulting in improved functionality and structural integrity.

Gas Assisted Injection Molding (GAIM): GAIM is a technique that introduces pressurized gas, typically nitrogen, into the mold during the injection process. This gas displaces the molten plastic from the center of the part, allowing for the creation of hollow sections or complex geometries.

GAIM reduces material usage, minimizes warpage, and enhances the overall strength-to-weight ratio of the final product.

In-Mold Decoration (IMD): IMD is a technique that combines plastic injection molding with decorative elements such as graphics, labels, or textures. The decorative film or foil is placed in the mold before the injection process, and the molten plastic encapsulates and bonds with the film, creating a durable and visually appealing surface finish.

IMD is widely used in the consumer electronics and automotive industries to achieve high-quality, customized designs.

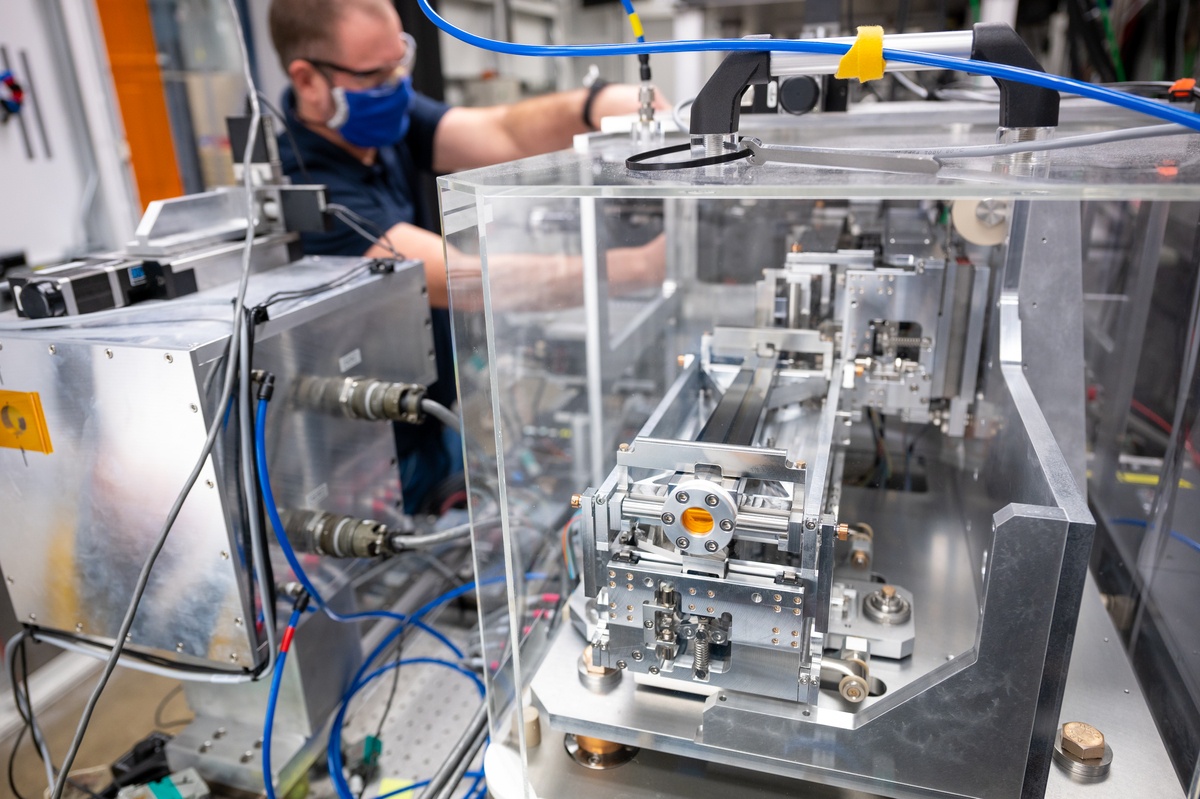

Micro Injection Molding: Micro injection molding is a specialized technique used to produce small, intricate parts with high precision. This technique utilizes extremely small molds and specialized injection machines capable of injecting tiny amounts of molten plastic.

Micro injection molding finds applications in the medical field, where small and precise components are needed for devices such as catheters, microfluidic chips, and surgical instruments.

How Plastic Injection Molding Manufactures Our Modern World

Plastic injection molding stands out as one of the most prominent and versatile techniques in the manufacturing industry. Its advantages in terms of versatility, efficiency, and cost-effectiveness have made it a go-to method for producing high-quality plastic parts. Moreover, advancements in plastic injection molding have led to the development of several advanced techniques that further enhance its capabilities.

Overmolding, insert molding, gas-assisted injection molding, in-mold decoration, and micro injection molding are just some of these advanced techniques employed in plastic injection molding.

These advanced techniques not only showcase the versatility of plastic injection molding but also contribute to the advancement and innovation in various industries. From automotive and electronics to medical devices and consumer goods, plastic injection molding plays a crucial role in manufacturing a wide range of products.

However, it is important to note that while plastic injection molding offers numerous advantages, the process requires expertise, careful design considerations, and quality control measures to ensure optimal results. Skilled engineers and technicians work closely with designers to develop molds, select suitable materials, and optimize process parameters to achieve the desired outcomes.

As technology continues to advance over time, we can expect further developments in plastic injection molding techniques. Continuous research and innovation are driving the industry toward more sustainable and environmentally friendly practices, such as the use of biodegradable polymers and recycling initiatives.

No comments yet