In the world of manufacturing and fabrication, versatility and adaptability are key. One material that embodies these qualities is vacuform plastic sheets. These sheets, made from thermoplastic materials, offer a wide range of applications across various industries. In this comprehensive guide, we'll delve into the world of Vacuform sheets manufacturers, exploring their characteristics, applications, and the benefits they offer to different sectors.

Understanding Vacuform Plastic Sheets

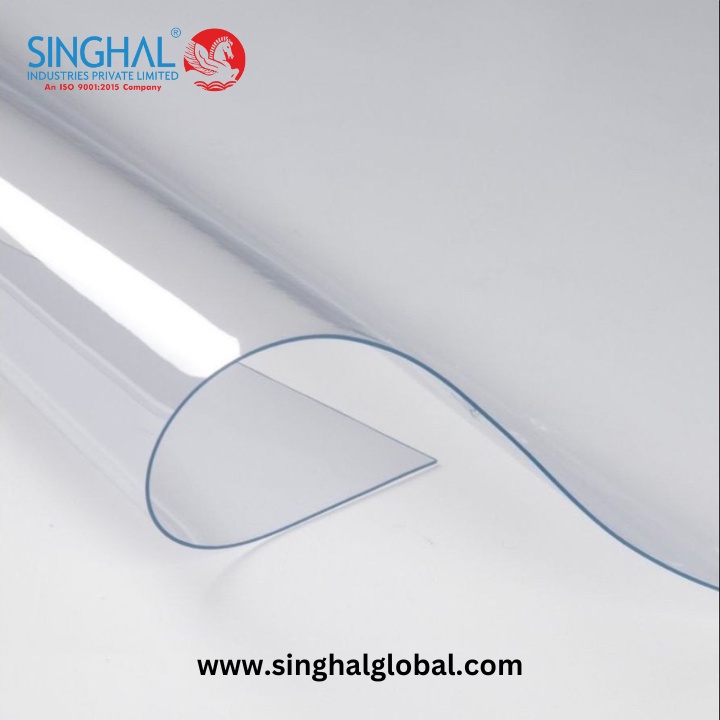

Vacuform plastic sheets, also known as vacuum-formed plastic sheets, are produced through a thermoforming process. This process involves heating a sheet of thermoplastic material, such as ABS (Acrylonitrile Butadiene Styrene) or polystyrene, until it becomes pliable. The heated sheet is then stretched over a mold or form using vacuum pressure, resulting in a precise and detailed replication of the mold's shape. Once cooled, the formed plastic sheet retains its shape and can be trimmed or finished as needed.

Characteristics of Vacuform Plastic Sheets:

- Lightweight: Vacuform plastic sheets are lightweight, making them easy to handle and manipulate during the forming process. This characteristic also contributes to their versatility, allowing them to be used in various applications without adding excessive weight.

- Durable: Despite their lightweight nature, vacuform plastic sheets are durable and resistant to impact, making them suitable for applications where strength and resilience are required.

- Versatility: Vacuform plastic sheets can be formed into a wide range of shapes and sizes, making them adaptable to diverse manufacturing and design requirements. They can replicate intricate details and textures, offering endless possibilities for creative expression.

- Cost-Effective: Compared to other manufacturing processes such as injection molding or machining, vacuum forming is a cost-effective method for producing plastic parts and components. Vacuform plastic sheets require minimal tooling and setup costs, making them an economical choice for small to medium-scale production runs.

- Customizable: Vacuform plastic sheets are highly customizable, allowing for the incorporation of features such as undercuts, inserts, and multi-color finishes. They can be tailored to meet specific design specifications and branding requirements, offering flexibility in product development.

Applications of Vacuform Plastic Sheets:

- Automotive Industry: Vacuform plastic sheets are widely used in the automotive industry for manufacturing interior and exterior components, such as dashboards, door panels, trim pieces, and grilles. Their lightweight construction and ability to replicate complex shapes make them ideal for automotive applications.

- Packaging and Display: In the packaging and display industry, vacuform plastic sheets are utilized for creating product packaging, blister packs, point-of-purchase displays, and signage. Their clarity, durability, and customizable features make them suitable for showcasing products and attracting customers' attention.

- Aerospace and Defense: Vacuform plastic sheets find applications in the aerospace and defense sectors for producing aircraft interiors, cockpit components, and protective equipment. Their lightweight yet durable properties meet the stringent requirements of these industries while offering cost-effective solutions.

- Medical Devices: In the medical field, vacuform plastic sheets are used for manufacturing medical device enclosures, equipment housings, and disposable medical supplies. Their biocompatibility, sterilizability, and ease of customization make them suitable for medical applications where hygiene and precision are essential.

- Toy and Hobby Industry: Vacuform plastic sheets are popular in the toy and hobby industry for creating model kits, figurines, and scenic elements. Their versatility and affordability make them an ideal choice for hobbyists and enthusiasts looking to bring their creative visions to life.

Benefits of Vacuform Plastic Sheets:

- Rapid Prototyping: Vacuform plastic sheets enable rapid prototyping and product development, allowing designers and manufacturers to iterate designs quickly and cost-effectively. This accelerates the product development cycle and reduces time-to-market.

- Lightweight Design: Vacuform plastic sheets contribute to lightweight design solutions, reducing the overall weight of products and components without sacrificing strength or durability. This is particularly advantageous in industries such as automotive and aerospace, where weight reduction is critical for performance and fuel efficiency.

- Design Flexibility: Vacuform plastic sheets offer design flexibility, allowing for the creation of complex shapes, textures, and finishes. This versatility opens up opportunities for creative expression and differentiation in product design.

- Cost-Effective Production: Vacuum forming is a cost-effective production method for manufacturing plastic parts and components in small to medium volumes. Vacuform plastic sheets require minimal tooling and setup costs, making them a cost-efficient choice for custom or low-volume production runs.

- Environmental Sustainability: Vacuform plastic sheets can be produced from recyclable materials, contributing to environmental sustainability and resource conservation. Additionally, vacuum forming generates minimal waste compared to other manufacturing processes, further reducing its environmental footprint.

Best Practices for Using Vacuform Plastic Sheets:

- Choose the Right Material: Select vacuum-placed plastic sheets that are suitable for the intended application in terms of material properties, such as strength, temperature resistance, and chemical compatibility.

- Optimize Mold Design: Design molds and forms with consideration for the material flow, uniformity of thickness, and ease of release. Ensure that the mold design accommodates the desired shape and dimensions of the final product.

- Control Heating Parameters: Maintain consistent heating parameters during the thermoforming process to achieve uniform heating and optimal material flow. Monitor heating temperatures, heating time, and cooling rates to prevent defects and ensure quality.

- Implement Quality Assurance Measures: Implement quality assurance measures to verify the dimensional accuracy, surface finish, and structural integrity of vacuform plastic sheets. Conduct regular inspections and testing to identify any defects or deviations from specifications.

- Consider Post-Forming Operations: Plan for post-forming operations such as trimming, finishing, and assembly to achieve the desired final product. Ensure that post-forming operations are carried out efficiently and accurately to meet quality standards and production schedules.

Conclusion

Vacuform plastic sheets offer a versatile, cost-effective, and environmentally sustainable solution for a wide range of manufacturing and fabrication applications. From automotive components and packaging to aerospace interiors and medical devices, vacuumed plastic sheets play a crucial role in bringing innovative products to life. By understanding their characteristics, applications, and benefits, manufacturers and designers can leverage the potential of Vacuform sheets manufacturers India to create high-quality, customized products that meet the evolving needs of the market.

Frequently Asked Questions (FAQs):

1. How does Singhal Industries ensure the quality and durability of its vacuform plastic sheets for diverse industrial applications?

Singhal Industries prioritizes quality at every stage of the production process. We utilize advanced manufacturing techniques and source high-quality thermoplastic materials to ensure that our vacuform plastic sheets meet rigorous industry standards for strength, durability, and dimensional accuracy. Additionally, our quality control team conducts thorough inspections and testing to verify the integrity and performance of each batch of vacuform plastic sheets before they are released to customers.

2. Can Singhal Industries provide customized vacuform plastic sheets to meet specific design requirements or project specifications?

Absolutely! At Singhal Industries, we understand that every project has unique requirements. That's why we offer customization options for our vacuform plastic sheets, allowing customers to specify their desired shapes, sizes, colors, and finishes. Whether it's for automotive components, packaging, or aerospace interiors, our experienced team works closely with clients to create tailored solutions that meet their exact design and performance needs.

3. How does Singhal Industries support customers with technical assistance and guidance in the selection and application of vacuform plastic sheets?

Singhal Industries is committed to providing exceptional customer support. Our knowledgeable team of experts is available to offer technical assistance, answer inquiries, and provide guidance on the selection, installation, and application of vacuform plastic sheets. Whether you have questions about material properties, forming techniques, or post-processing options, we're here to help you find the right solution for your project.

No comments yet