Low-volume injection molding is among the popular manufacturing processes used to churn out plastic parts in small quantities. If you’re into short-run production, product development, and prototyping, then injection molding is the go-to process. That’s why more and more injection molding manufacturers invest in this process. Still, thinking about the upsides of putting your money on low-volume injection molding? Well, then, read on because this blog is dedicated to exploring the benefits of this injection molding process.

Benefit #1: Cost-Effective

High-volume injection molding is costly, especially if you want small quantities of a particular part. Enter low-volume injection molding, where the cost of every mold is lower when compared to its high-volume counterpart. The best part? Low-volume injection molding doesn’t tether you with any minimum order quantities.

Benefit #2: Flexibility

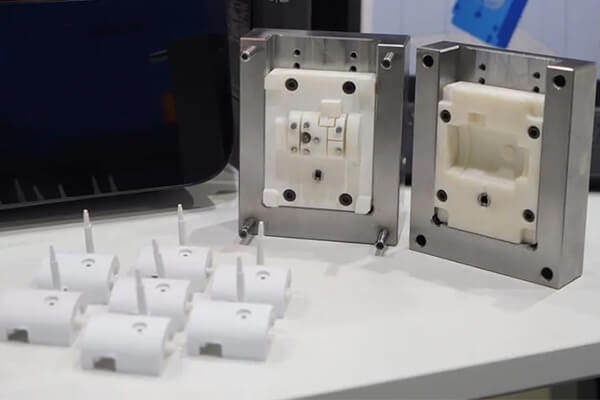

When it comes to process flexibility, low-volume injection molding is matchless. After all, you can leverage this process to produce a humungous number of parts, from extremely complicated to dead simple. On top of that, this molding form can help you introduce any design-specific changes to the parts easily and blazingly fast.

Benefit #3: Quality

Low-volume injection molding can offer great help to create quality parts with impeccable precision and amazingly high accuracy. Why? Because the process is so tightly controlled, the scope of errors is the bare minimum. So, if you want your parts to have high accuracy and flawless precision, you won’t go wrong with the molds you’d get from low-volume injection molding.

Benefit #4: Speed

Low-volume injection molding companies can help you produce parts at a superior pace. Why? Well, the reason behind the speed is one simple fact – the size of the molds is smaller, so they’re easier and faster to cool down and heat up. Better yet, a low-volume injection molding manufacturer will have small production runs and will be able to improve your time to market effectively.

Benefit #5 Customization

Do you want custom parts and want to keep the volume low? If you nod in the affirmative, investing in low-volume injection molding will surely be your best bet. But why’s that, you may ask? This is because the low-volume variant of the molding process can have molds made as per your specific requirements.

Finding a perfect low-volume injection molding manufacturer

Selecting the right low-volume injection molding company is easier said than done. This is why we’ve compiled a few tips to help you start your journey to find an ideal manufacturer for yourself.

- Experience: Ensure the manufacturer has vast experience working with low-volume injection molding.

- Speed: Inquire about the lead time of the manufacturer.

- Quality: Understand the manufacturer's quality control processes for the production process.

- Pricing: Always receive quotes from different manufacturers before making a final decision.

Wrapping It Up

No doubt, low-volume injection molding is a flexible, quality-centric, and cost-effective manufacturing process. These factors make this molding process the best bet for many applications. So, the bottom line is simple – if you want to churn out only a small quantity of plastic parts, then low volume will be the best option for you.

No comments yet