Examining CNC Milling Services' Benefits for Precision Manufacturing

To the world of precise manufacturing, welcome! Modern organizations want cutting-edge solutions that can provide the highest levels of quality, accuracy, and efficiency in the fast-paced, highly competitive market of today. That's the situation with CNC milling services. Our ability to precisely and painstakingly build complex parts and components has been completely transformed by these cutting-edge technologies. Whether you work in the automotive, aerospace, or any other industry where excellence is required, CNC milling services can help you increase the efficiency of your production. So grab a seat, and let's explore the benefits of CNC milling services for precision production. Get ready for an incredible experience using cutting-edge equipment and revolutionary methods that will leave you wanting more!

High-quality Machining in the Prospects

Quality is paramount in the dynamic realm of production. Precision is now absolutely necessary, as opposed to being a luxury in the past. You may be sure that every part and component satisfies the highest standards of quality if you have access to CNC milling services. With no space for mistakes or irregularities, these sophisticated robots produce complex designs with perfect accuracy thanks to computer-controlled technology.

However, how does CNC machining differ from conventional techniques? By automating the entire process, human error is eliminated. Less errors and more consistent outcomes throughout several production runs are the results of this. When working with metals like titanium or aluminum, or even more unusual materials like carbon fiber composites, CNC milling machines provide unmatched versatility.

In addition, compared to manual machining techniques, CNC milling services offer higher efficiency and quicker turnaround times. Increased productivity and shorter production times are the outcomes of the automation's ability to operate continuously without rest periods or tiredness. Businesses get a competitive edge in fulfilling deadlines without sacrificing quality, in addition to saving important resources.

Investing in CNC milling services is a wise choice if you want to future-proof your production operations because technology is advancing at a rapid pace. Accepting this ground-breaking technique that ensures exact outcomes each and every time will help to establish new standards for high-quality machining that will influence industries for years to come.

Every task requires precision machining.

One size does not fit all when it comes to precise machining. Every task has specific requirements and needs of its own. Here's where services for precision machining come in. With the help of these services, every project's unique requirements are met, guaranteeing that each component is expertly made.

You should only settle for perfection when it comes to precise machining. Precision machining may handle large or small jobs, such as sophisticated components for aeronautical engineering or delicate pieces for medical devices. Tight tolerances and accurate measurements are made possible by the sophisticated technology and experience supporting these services, which provide immaculate final goods.

There is no sector or application where precision machining cannot be used. CNC milling services are a flexible answer for any task requiring premium components, from the production of electronics to the automobile industry. CNC milling service providers can consistently produce outcomes since they have access to modern equipment and knowledgeable operators.

Precision machining guarantees that every component meets precise specifications, regardless of the complexity of your project or the materials used. You can rely on CNC milling services to complete the task correctly whether you require aluminum or stainless steel components machined with the highest precision and attention to detail! When you can get exact outcomes that are catered to your needs, why would you settle for anything less? Selecting precision milling will ensure optimum quality without sacrificing any aspects.

Services for Accurate CNC Milling

In the field of precise manufacturing, precision CNC milling services are essential. Technology has advanced to the point where CNC milling is now more precise and efficient than traditional manual machining.

In CNC milling, material is removed from a workpiece with extreme precision and accuracy by means of computer-controlled machinery. This facilitates the creation of elaborate designs and complex shapes. The unparalleled precision of CNC milling services guarantees that every piece satisfies strict tolerance requirements, whether it is for large-scale production runs or prototypes.

Its adaptability is one of the main benefits of CNC milling services. These machines can work with any kind of material that you need parts created of, including plastic, wood, and metal. For industries like aerospace, automotive, medical devices, and many more, the flexibility to deal with different materials opens up unlimited possibilities.

Apart from its adaptability, CNC milling also provides quick turnaround times without sacrificing quality. Because these automated equipment can operate without human intervention for extended periods of time, productivity may be boosted and project lead times can be shortened. This efficiency helps producers cut costs by saving time as well.

It's understandable why CNC milling services have grown to be a vital resource in today's precise manufacturing sector given its unmatched precision and versatility as well as quicker turnaround times at cheaper prices.

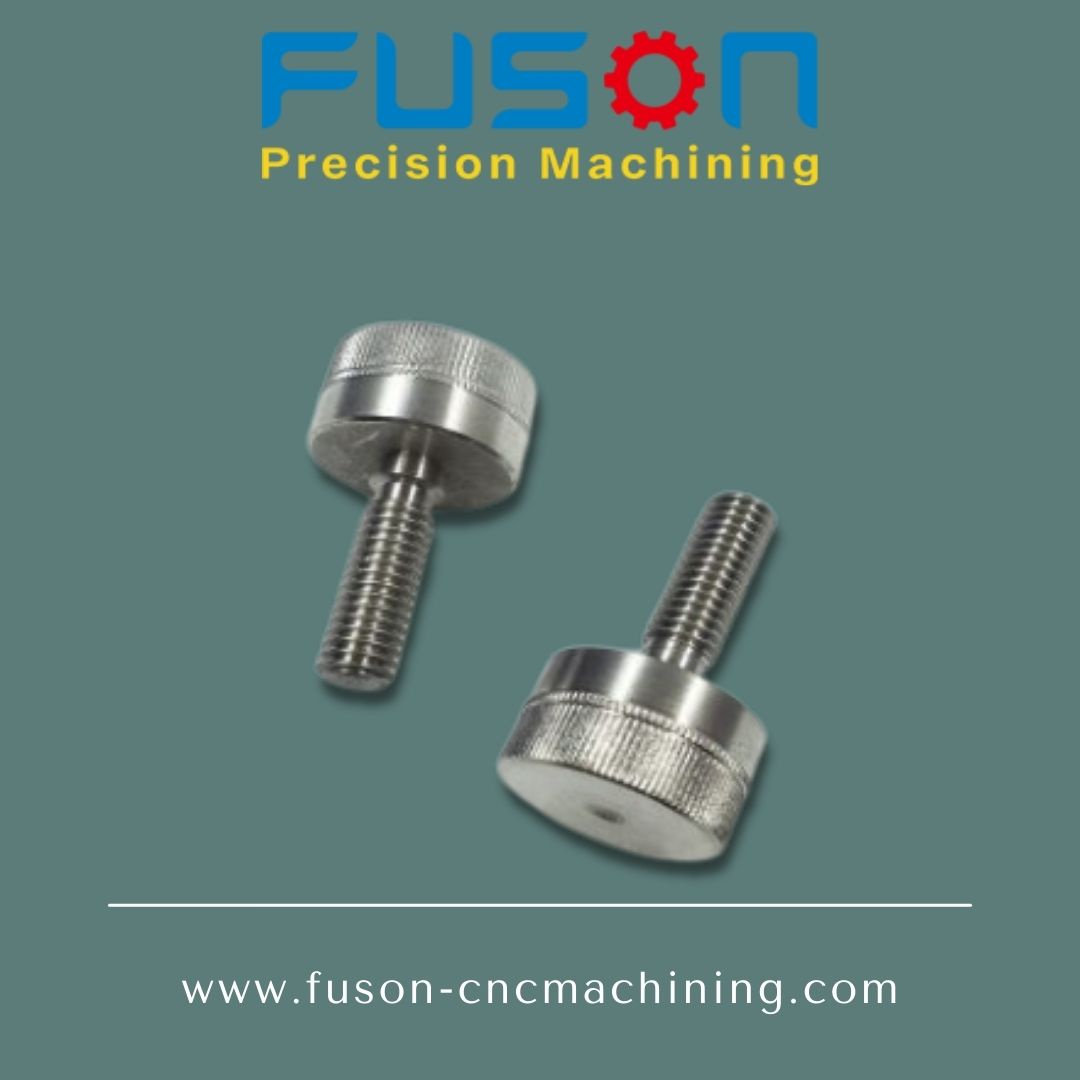

Pieces machined precisely with a CNC

CNC machining services are essential to the production of excellent parts with remarkable accuracy in precision manufacturing. The capacity to generate elaborate shapes and complex geometries that would be practically impossible to do manually is one of the main advantages of CNC precision machining parts. Manufacturers may create items with precise tolerances and reliable quality by using computer-controlled machinery.

Furthermore, items created with CNC precision machining have unmatched repeatability, guaranteeing that every part meets the given standards. This degree of uniformity is crucial in sectors like aerospace and automotive where even minute deviations can have serious repercussions. For each production run, enterprises using CNC milling services can count on accurate measurements and low human error.

The ability to work with a variety of materials is another benefit of CNC precision machining parts. These machines can handle a wide range of materials with ease, including plastic polymers and metals like aluminum and stainless steel. This adaptability enables producers to serve a broad spectrum of markets and uses without sacrificing effectiveness or quality.

For precision manufacturing operations, CNC precision machining parts have many benefits. These technologies transform the way manufacturers approach difficult projects, from easily generating elaborate designs to ensuring consistent quality throughout manufacturing runs. CNC milling services offer an essential way to efficiently produce high-performance components because of its adaptability in working with various materials and the precise tolerances they can attain through computer control systems.

Aluminum components with precise milling

In the realm of precision manufacturing, CNC milling services are essential to producing precise and high-quality goods. Precision milled aluminum parts are one application where CNC milling excels.

Aluminum is a popular lightweight and durable material that finds application in a wide range of industries, including electronics, automotive, and aerospace. With the use of CNC milling services, producers can easily construct complicated forms and elaborate designs.

There are many benefits to use CNC machining for precisely machined aluminum components. The accuracy that can be attained is the most important factor. Precision measurements and tight tolerances are guaranteed by the cutting-edge technology employed in CNC machines, producing parts that fit together flawlessly.

Faster production speeds are also possible with CNC milling as opposed to conventional machining techniques. It is possible to produce several pieces at once without sacrificing quality when using automated procedures and computer-controlled operations.

Additionally, because to CNC milling's adaptability, producers may deal with a variety of aluminum alloys. Both 6061 and 7075 aluminum can be carefully machined to suit certain specifications, including strength or resistance to corrosion.

An additional benefit is the economical nature of CNC milling services when it comes to creating precisely machined aluminum components. Manufacturers can reduce waste and save time by doing away with human mistake and optimizing cutting patterns to minimize material waste.

A reliable miller machine shop's CNC milling services are the best option for precise production demands, such as producing complex forms or elaborate designs out of lightweight yet robust materials like aluminum. For producers in a variety of industries hoping to stay competitive in today's market, this cutting-edge technology opens up a world of possibilities, from assuring accuracy to cutting production times and costs.

No comments yet