From Waste to Energy: Establishing a Palm EFB Pellet manufacturing that is prosperous Line

Are you searching for a green and way that is efficient dump your palm oil industry waste and generate energy that is clean? Search no further than establishing a palm that is pellet production line that is successful! Here you will find the advantages, innovation, security, use, how to utilize, solution, quality, and application of producing and palm that is utilizing pellets.

Advantages

Palm fruit that is empty (EFBs) are agricultural waste generated in large quantities by the palm oil industry. In the place of letting the EFBs Compost Turner rot or burning them openly, which pollutes the air and soil, they may be became pellets that are valuable biomass energy for power plants and boilers which can be industrial. Unlike traditional fossil fuels like coal and gas, burning palm EFB pellets releases fewer harmful gases and has lower CO2 emissions, which might help combat climate modification and protect the environment. Another advantage is the financial great things about creating market that is new palm EFB pellets, which increases revenue and job opportunities for neighborhood farmers and industry workers.

Innovation

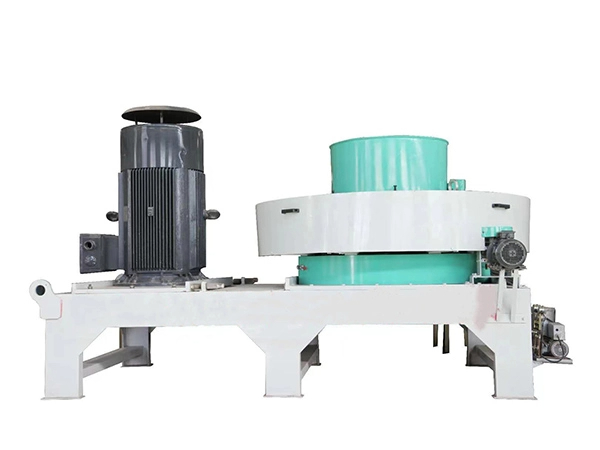

The success of establishing a palm EFB pellet manufacturing line is reliant on innovation in equipment and technology. The manufacturing process is optimized to make certain effectiveness that is high constant quality of pellets with advanced pellet mills, hammer mills, dryers, and conveyors. Plus, some manufacturers have actually developed a kind that is new of EFB pellets called densified palm EFB (DP-EFB) pellets, which are denser and more durable than regular palm EFB pellets, with better storage and transportation properties.

Safety

Security is paramount in producing palm EFB pellets, as some risks exist in the method, such as for instance fire and explosion hazards whenever handling and EFBs being drying. To prevent accidents, strict safety measures should really be implemented atlanta divorce attorneys phase, such as using modern gear with automatic control systems, professional training for operators, regular upkeep, and fire extinguishing systems. Plus, palm EFB pellets are safe to make use of as fuel, as they don't produce sparks and also relatively moisture content that is low.

Use

Palm EFB pellets have various applications, mainly as gas for energy generation, such as in biomass energy plants and boilers which are industrial. They could also be used as animal feed, soil amendment, and being a material that is natural making paper, fiberboard, as well as other lumber items. In comparison to wood that is regular, palm EFB pellets have greater value that is calorific reduced ash content, and less clinker development, which enhances their combustion effectiveness in power plants.

How to Use

A combustion device is necessary, such as for instance a pellet stove, boiler, or furnace to make use of palm EFB pellets. First, the pellets are given into the device, and then ignited by an automatic or ignition system that is manual. While the pellets burn, they release heat energy, that can be harnessed for electricity or heating manufacturing. The ash generated from burning palm EFB pellets is also a byproduct that is valuable since it has high content that is nutrient can be used as organic fertilizer.

Service

To make sure the establishment that is prosperous of palm EFB coco pellets production line, manufacturers should provide solutions that are comprehensive such as installation, commissioning, operation training, and upkeep. They should also be attentive to customer inquiries and have actually competitive pricing and service that is after-sale. A sustainable palm EFB pellet market could be developed with the cooperation of the product manufacturers, palm oil mills, and electricity companies.

Quality

The grade of palm EFB pellets is vital in determining their market performance and value. Top quality pellets should have value that is high is calorific low ash content, low moisture content, and uniform size and form. To reach consistent quality, manufacturers should utilize top-quality raw materials, such as fresh EFBs with low impurities, and adopt advanced technology and equipment to ensure the correct drying and process that is pelleting. Regular evaluating and quality control should be set up also to monitor the pellet quality.

Application

The applying of palm efb pellet process is not limited to the palm oil industry but has wide-ranging benefits for the energy and sectors that are environmental. Through the use of palm EFB pellets, energy demand can be met sustainably, reducing reliance on traditional fossil fuels and reducing greenhouse gasoline emissions. A circular economy is created, where waste from one industry is turned into a valuable resource for another industry, advertising sustainability and innovation during the exact time that is same.

Establishing a palm that is pellet that is successful line is a green, efficient, and revolutionary method to transform waste into energy and generate economic benefits. With proper safety measures, advanced technology, comprehensive service, and good quality control, palm EFB pellets could be widely applied into the energy, environmental, and commercial sectors, creating a future that is sustainable.

No comments yet