In the world of product development and manufacturing, managing costs can be a real headache. But fear not, there's a hero in the form of Siemens PLM (Product Lifecycle Management), here to rescue you from those pesky cost management woes. In this article, we'll explore how Teamcenter helps resolve some common pain points in product cost management, using real-world examples.

The Costly World of Product Development

Creating a new product, whether it's a car, a smartphone, or a piece of machinery, can be an expensive journey. From sourcing materials to optimizing manufacturing processes, every decision impacts the final cost. That's where Teamcenter comes to the rescue.

Pain Point 1: Accurate Cost Estimation

One major headache in product cost management is getting accurate cost estimates. Imagine you're designing a new car, and you need to know how much it'll cost to produce. Teamcenter uses its magic to gather real-time data from different sources, like suppliers and manufacturing teams, to give you precise estimates.

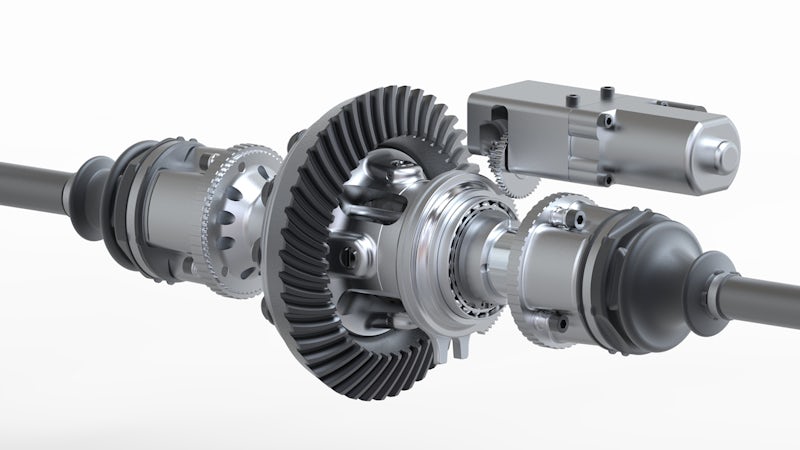

Example: American Axle & Manufacturing (AAM), a leading automotive supplier, leverages Siemens Teamcenter to effectively manage costs in their product development processes. Teamcenter allows AAM to meticulously track and analyze cost data throughout their manufacturing and design operations. This enables AAM to make data-driven decisions, optimize their product designs, and identify cost-saving opportunities. By integrating Teamcenter into their cost management workflows, AAM can enhance efficiency, control expenses, and maintain competitiveness in the automotive industry, ultimately delivering high-quality products to their customers while managing costs effectively.

Pain Point 2: Supply Chain Surprises

Supply chain disruptions are like unexpected plot twists in a movie. They can wreak havoc on your budget and timelines. Teamcenter acts as a crystal ball, helping you spot potential disruptions early. It tracks and analyzes supply chain data, so you can prepare for the unexpected.

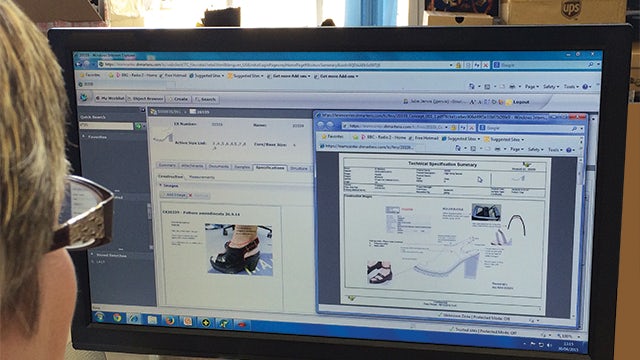

Example: Dr. Martens, the renowned footwear brand, has harnessed the power of Teamcenter to effectively manage its global supply chain. In the fast-paced fashion industry, supply chain disruptions are common, ranging from changes in demand to unexpected logistical challenges. By implementing Teamcenter, Dr. Martens can monitor its supply chain in real-time, anticipate potential disruptions, and swiftly adapt to changing circumstances. This proactive approach not only minimizes costly surprises but also ensures that the iconic Dr. Martens boots reach their loyal customers reliably and on time, maintaining the brand's reputation for quality and style.

Pain Point 3: Design Changes and Cost Impact

In product development, design changes are inevitable. But they can be costly if not managed properly. Teamcenter keeps track of design revisions and instantly calculates their impact on costs. This ensures that changes don't blow your budget.

Example: Northrop Grumman, a global aerospace and defense technology company, harnesses the power of Teamcenter PLM to streamline their design change management processes and assess the associated cost impacts. When design modifications are proposed in their complex aerospace and defense projects, Teamcenter's robust capabilities enable Northrop Grumman to swiftly evaluate how these changes will affect the overall project costs. This real-time cost analysis ensures that decisions are made with a comprehensive understanding of the financial implications, allowing Northrop Grumman to maintain cost-efficiency while delivering cutting-edge solutions for national security and aerospace advancements

Pain Point 4: Vendor and Supplier Management

Dealing with vendors and suppliers can be a headache. Teamcenter simplifies vendor and supplier management by centralizing communication and data sharing. This improves collaboration, reduces errors, and ensures cost transparency.

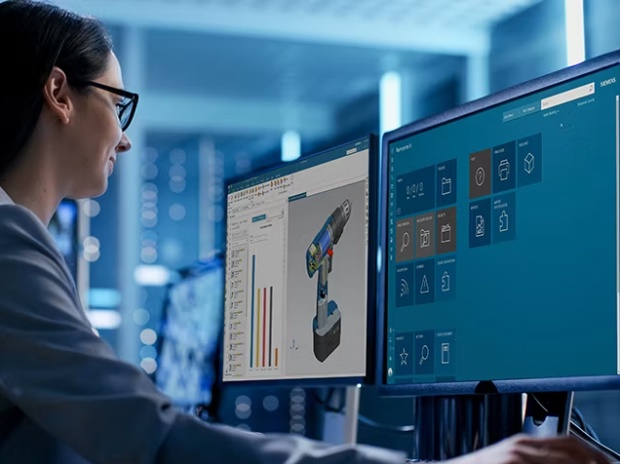

Example: Siemens Healthineers, a medical device company, relies on Teamcenter to collaborate with suppliers. It helps them streamline supplier relationships and manage costs effectively while producing life-saving medical equipment.

Teamcenter - Your Cost-Saving Sidekick

In the complex world of product cost management, Siemens Teamcenter Cost Management Software emerges as the ultimate sidekick. With its ability to provide accurate cost estimates, predict and mitigate supply chain disruptions, manage design changes, and simplify vendor relationships, Teamcenter is your cost-saving hero. It's the tool that ensures you stay on budget, meet deadlines, and bring your innovative products to market without breaking the bank. So, the next time you're tackling the challenges of product cost management, remember that Teamcenter is your trusty partner, here to make your journey smoother and more cost-effective.

Get Free Siemens PLM Software Trial Now!

No comments yet